Specially designed for electric marine BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 8KW / 5KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

As global industries transition toward greener development, electric ships have become a key area of technological upgrading. As the power source of ships, the safety and performance of batteries directly depend on a set of key technologies: the marine BTMS (Battery Thermal Management System). This intelligent temperature management system, designed specifically for marine lithium-ion batteries, utilizes advanced liquid cooling technology to ensure safe operation of battery packs in complex marine environments. Its primary functions include safety monitoring, energy efficiency optimization, and life extension. It is suitable for a variety of applications, including ro-ro passenger ferries, cargo ships, fishery administration vessels, and new energy vessels.

Marine battery thermal management systems (BTMS) and electric bus BTMS share core functionalities: both require precise temperature control, efficient balancing, and intelligent management to ensure battery safety and performance. However, the more specialized environments of marine BTMS require some differences in their technical implementation path compared to electric buses.

1. Salt spray and humid environments: Ships operate in high salt spray and high humidity environments, requiring BTMS system to possess enhanced corrosion resistance.

2. Vibration and shock: The continuous vibration and shock generated during ship operation necessitate reinforced mounting structures to ensure system stability.

| Model | 10CW | 8R | 5CW | 5R |

| Cooling Capacity | 10KW | 8KW | 5KW | 5KW |

| Standard Dimensions | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 750*550*293mm |

| Standard Weight | 40kg | 40kg | 30kg | 40kg |

| Air Outlet Direction | Side | Top | Side | Top |

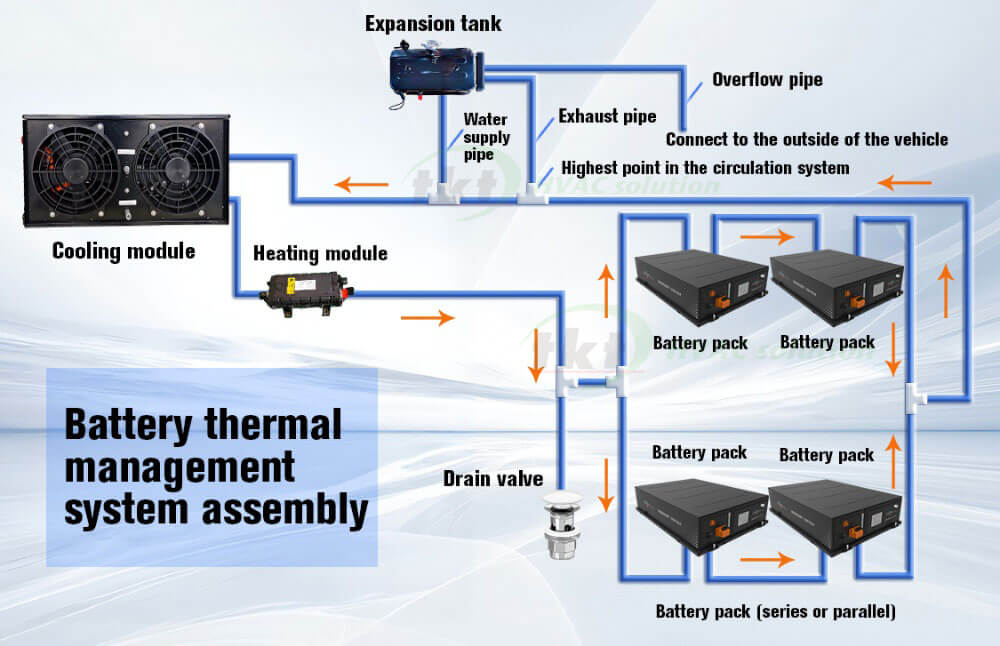

The coolant absorbs heat from the battery module, flows through a plate heat exchanger, transfers the heat to an external cooling system, and then returns to the battery module for a repeat cycle after cooling itself.

1. Liquid Cold Plate: Integrated within the battery pack, it utilizes highly thermally conductive material to maximize contact area.

2. Electronic Water Pump: Provides a stable coolant flow and serves as the power source.

3. Expansion Tank: Compensates for thermal expansion and contraction of the coolant, preventing cavitation.

1. “Battery Thermal Management System for Electric Vehicles and Battery Life” Click here to view

2. “Analysis of Battery Cooling System For Electric Bus, Truck” Click here to view

3. “Battery Liquid Cooling System – How Does It Work?” Click here to view

4. “BYD K9 Project: EV Battery Cooling System Combined with Bus A/C” Click here to view

5. “BTMS Battery: Principle, Design, Installation – TKT HVAC” Click here to view

6. “Battery Thermal Management System for Truck / Bus etc. – Supplied to Top 500 TATA” Click here to view

7. “Battery Thermal Management System for Switch Mobility – TKT” Click here to view

8. “Custom Battery Thermal Management System (BTMS) – TKT HVAC” Click here to view

9. “How to Design Bus BTMS Installation Location” Click here to view

10. “Battery Cooling | Battery Thermal Management System – TKT” Click here to view

Click to browse BTMS solutions for electric buses

Click to browse BTMS solutions for electric trucks

Click to browse BTMS solutions for electric heavy equipment

Click to browse BTMS solutions for electric marine

Click to browse OEM customized BTMS solutions

This article will use some failed cases to illustrate the risks of EV charging station investment. Don’t miss it if you’re interested!

Understand the 60kW EV Charger: Your Preferred Choice for Fast and Efficient EV Charging Solutions. TKT is a professional manufacturer.

The electric three wheeler rickshaw has become the best choice for short-distance commuting in cities and rural areas.