OEM&ODM

We are a leading manufacturer of new energy vehicle equipment based in China, offering Battery Thermal Management Systems (BTMS), Electric Vehicle Air Conditioners (EV A/C), and Electric Vehicle Chargers.

TKT keeps an engineer team with 135 members, such as design engineer, structure engineer, electrical engineer, testing engineer, EMI/EMC engineer, after sales engineer ect., and has the complete ability design, development, testing and certification. At the same time, TKT has the national standard laboratory for bus air conditioner testing, which can simulate 60 Deg. C ambient temperature and sunlight, and can also do the vibration test in house.

For production, TKT has an experienced assembling team with 480 members, who already worked for TKT more from 5-20 years, and the abundant experience can guarantee the 0 defect of all TKT products and pass the test.

Meanwhile, TKT holds an experienced after sales team in China and world widely, which can provide local service in more than 85 countries in the world, and fulfill the after sales technical support from all the OEM world widely.

As a leading manufacturers of vehicle air conditioners, BTMS and EV chargers in China, TKT Busthermo has been supplied to BYD, YUTONG, Golden Dragon, Yaxing, Ankai, Neoplan, Hengtong, Shenlong, Foton and Nanjing Golden Dragon ect main bus manufacturer in China, and also do OEM to TATA Motor, Marcopolo, Daewoo, Isuzu, MAZ, INCARVEN, MODABUS, GET ect bus manufacturer in the world. Those rich experience and over 20 years of market verification prove that TKT HVAC Busthermo solutions is trustworthy.

With the assistance of the TKT China and TKT India teams, the bus air conditioner have been successfully installed on Olectra’s new buses.

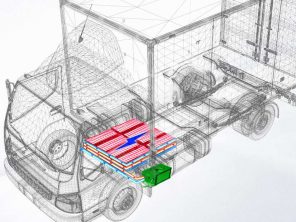

Provider of Battery Thermal Management System for Truck Bus. TKT is available in a variety of performance and size models.

With cooling capacity of 10 kW and heating capacity of 6 kW, the battery thermal management system was designed for British bus manufacturer.