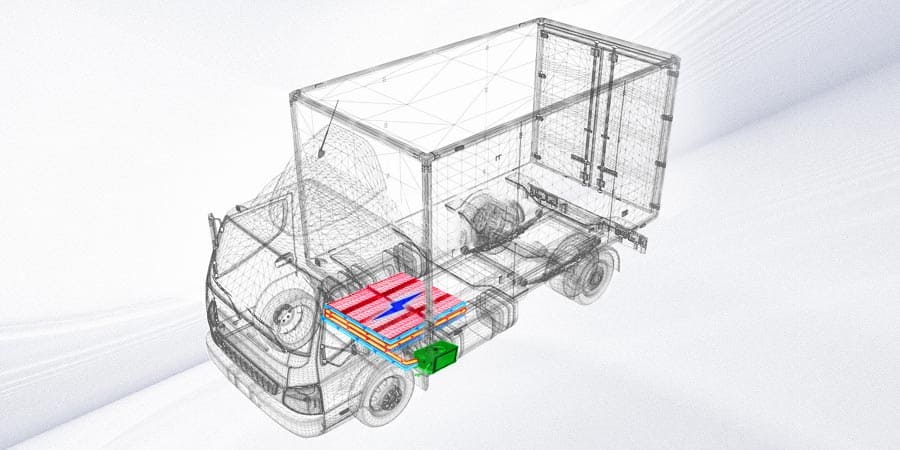

Battery thermal management system is an important part of electric vehicles. Battery Thermal Management System for Truck corresponds to electric trucks. The system is used to effectively control the temperature of electric truck batteries. During the operation of an electric truck, the battery temperature will rise continuously and it must be cooled. If the battery temperature is too high, it will reduce the battery performance, damage the battery life, reduce the safety of the electric truck, and even cause an explosion in serious cases. Therefore, a battery thermal management system is a necessary part of truck electrification.

TATA motors, one of the world's top 500 companies

TKT has first-class technical strength and has had a customised cooperation project with TATA motors for air conditioning and Battery Thermal Management System for buses as early as 2018. The first batch of order was co-operated more than 400 units. As we all know, TATA motors, a Fortune 500 company, is very strict in its selection of suppliers. Our product performance, quality and service have been fully trusted and recognised by them over the past 6 years.

This year, our cooperation goes one step further. We were awarded custom development of Battery Thermal Management System for Truck. This is their new electric light truck development project. Currently, the project is still in the testing phase and has not yet entered mass production. The following video is of a test truck in action. The whole process seemed very stable and smooth. We believe that in the near future, we will carry out mass production and our cooperation will go further.

In addition to TATA, we have a number of partners in the BTMS programme. For example, BYD, Switch mobility, greenmot and many more.

Contact us now to get solutions from the experts.

Condenser coil, condenser fan, water tank, water pump, heat exchanger, electric compressor, control panel, CAN module, expansion valve, etc.

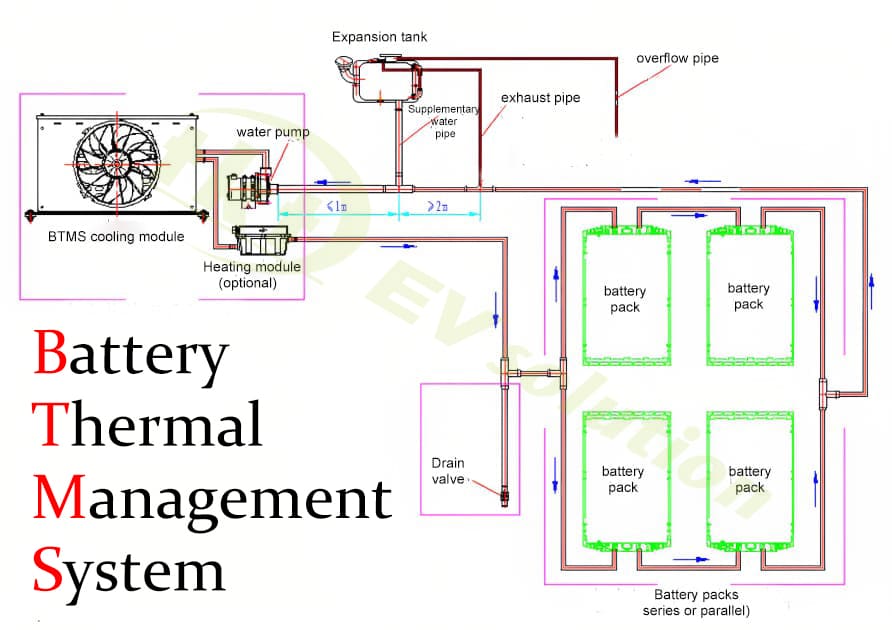

The condenser system cools down the coolant and the water pump will run the coolant through the battery cooling system (another name for Battery Thermal Management System) and the battery structure system to release the heat generated by the battery pack.

The BTMS is a part of the battery management system(BMS). It operates automatically according to the instructions of the battery management system. It will automatically switch on the cooling or heating mode according to the actual temperature around the battery. No manual intervention is required once the settings are complete.

TKT's BTMS uses can control throughout. The general process is that the battery management system first sends a request for cooling or heating and a target water temperature. The BTMS then automatically adjusts the real-time speed through advanced algorithms based on the difference between the outlet water temperature and the target water temperature.

1, Temperature Measurement:

The battery cooling system(BCS) first measures the temperature of the battery through sensors. The temperature measurements of the battery are transmitted in real time. Feedback to the battery management system(BMS).

2, Temperature Analysis:

The battery management system(BMS) analyses the collected temperature data and determines the actual working condition of the current battery. This process is real-time and ongoing.

3, Temperature Control:

On the basis of temperature analysis, the battery management system(BMS) will be used to issue a variety of instructions to manipulate the thermal management system. There are three main types: heating, cooling, maintenance reminders. And according to the analysis data, the water flow and fan speed and other real-time adjustment.

4, Temperature Monitoring:

In order to ensure the accuracy of battery temperature control, the battery cooling system(BCS) will monitor the battery temperature in real time. To fully ensure the performance and safety of the battery.

Cheapest System: Air-cooled system, where the battery is cooled by the surrounding air, simple and easy to maintain, but least efficient.

Limitations of Application: phase change material cooling system, using the characteristics of heat absorption and evaporation of phase change material for cooling, with no noise and energy saving. But there are more limitations.

Future Development Direction: submerged cooling system, is the entire battery and equipment completely submerged in a special cooling medium, this liquid has excellent thermal conductivity, can quickly absorb and disperse the heat generated by the equipment, so that the temperature of the equipment to maintain in the appropriate range. The system is currently unstable and is only one of the mainstream future research directions.

Currently the most practical and commercially viable is: liquid cooling system, that is, through the circulation of coolant to cool the battery, high efficiency and stability, TKT's Battery Thermal Management Systems(BTMS) belongs to this type. TKT has a variety of product models (learn more), can solve a variety of commercial electric vehicle battery temperature problems.

Electric heavy duty trucks, electric light duty trucks, electric construction vehicles, electric agricultural vehicles, etc. These large vehicles generally require long mileage or hours of operation, and usually require a large power output. Therefore their battery loads will all be large and generate a lot of heat. If they are not cooled down in time, overheating as well as spontaneous combustion can occur very easily.

Battery Thermal Management System for Truck have not been mentioned very often, mainly because of the difficulty of Truck Battery Thermal Management compared to smaller vehicles. And because the electrification of electric trucks is slow, there are fewer companies in the research. TKT has more than 10 years of research and manufacturing experience in this field, with a variety of commonly models (learn more) and also offers customized solutions.