For personal safety: anti-electricity of the shell, plug insulation detection, leakage protection, control module self-test function, power off immediately when the cable falls off, etc.

For vehicle safety: overvoltage protection, undervoltage protection, overcurrent protection, short circuit protection, Battery anti-reverse connection, BMS independent security protection, etc.

For product safety: High quality military grade components. IP55 protection level, Anti-rain and snow, dust, rust and so on. Real-time detection of security protection, alarm feedback, flame retardant, etc.

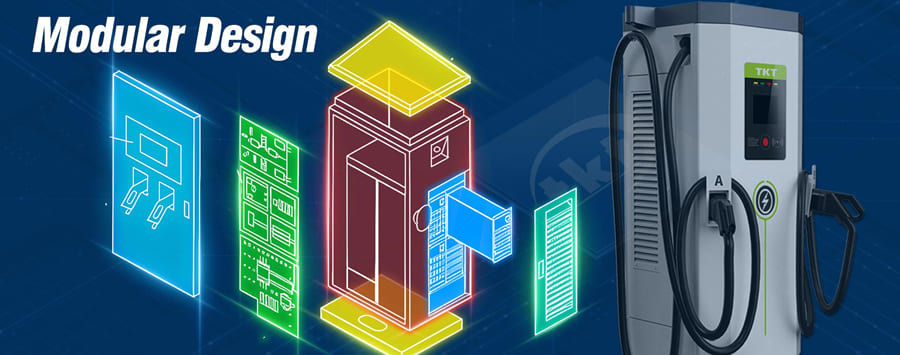

Easy to upgrade: With technological progress or changes in charging power requirements, each module of the charging pile can be directly upgraded to meet new changes. Can save costs.

Easy maintenance and repair: Perfect troubleshooting system, quickly find problematic modules, and replace modules independently. This saves maintenance costs and reduces technician requirements.

The time saved can increase the number of bus and truck trips; it can increase the number of paid charging of EV. Faster charging speeds bring higher profit margins and convenience.

In order to feel the charging speed more intuitively. I made the form. I will use 65kwh as an example. (If you can't calculate, our experts can help, please contact the experts)

| Electric Vehicle Battery Capacity | Charging Speed | Total Time to Fully Charge | Average Miles Gained Per Hour |

| 65kwh | Level 1 speed: 3kw | 21.67h | 10.5mi / 16.8km |

| Level 2 speed: 7kw | 9.29h | 24.5mi / 39.2km | |

| Level 2 speed: 11kw | 5.91h | 38.5mi / 61.6km | |

| Level 2 speed: 22kw | 2.95h | 77mi / 123.2km | |

| Level 3 speed: 180kw | 22min | 630mi / 1008km |

Through real-time monitoring, the reasonable distribution and balanced utilization of electric energy among multiple charging piles can be realized to improve charging efficiency, charging pile utilization rate and stability.

User terminal: color LCD touch screen, supports multiple languages, simple design close to the owner's use. Multiple payment methods are supported.

Management side: intelligent management, remote monitoring, fast and convenient. Various statistics are clear. Easily connects to any OCPP-based backend.

As a leading DC EV Charger Manufacturers, we has more than 10 years of technology accumulation, more than 100 patents, supports OEM&ODM, provides white label, customized management system, etc.

TKT is a DC EV charger manufacturers in China. We own a number of core patented technologies, which make our chargers charge faster, the system simpler and better to use, and easier to maintain and repair.

New Design of DC EV Charger

The full name of DC EV charger is Direct Current Electric Vehicle Charger. It is connected to the AC power grid, through which it realizes the process of changing AC power to DC power outside the vehicle. The DC power is then fed directly into the battery of the electric vehicle at a faster rate, which effectively fulfills the requirement of fast charging.

For a more detailed look at one of the processes, see another article: "How Do EV Charging Stations Work?"

TKT, as a mature DC EV Charger Manufacturers, has more than 10 years of design and manufacturing experience and holds core patents. We mainly take the following approaches:

1. Adopt high power charging technology: DC charger adopts high power charging technology, which can convert grid AC power into DC power and adjust output voltage and current according to the system in real time, so as to adapt to the charging demand of power batteries of different types of electric vehicles.

2. Multi-circuit parallel charging: DC charger adopts multi-circuit parallel charging method, which can charge multiple electric vehicles at the same time. This can fully utilize the output power of the charger, improve charging efficiency and shorten charging time.

We have a wide range of solutions for DC EV chargers. Different configurations are available for different regions. From charging power to charging connectors to the number of connectors. Click here for more details.