It is also known as battery thermal management system (BTMS), or battery cooling system (BCS), or electric battery thermal management (eBTM), or battery cooling, or battery pack cooling system. The main purpose is to ensure that the battery pack can discharge power within the optimum temperature range. This ensures maximum stability and efficient power release. At present, the technology in this area of small cars is relatively simple. But that's rare for larger vehicles like electric buses and electric trucks. This is because the battery pack of a larger vehicle generates more voltage and current during operation. This requires more expertise.

The global climate continues to heat up, and the increasing severity of climate disasters in recent years illustrates the seriousness of the matter. Protecting the environment is becoming a growing concern around the world. Countries are inclined to start adopting electric buses and electric trucks.

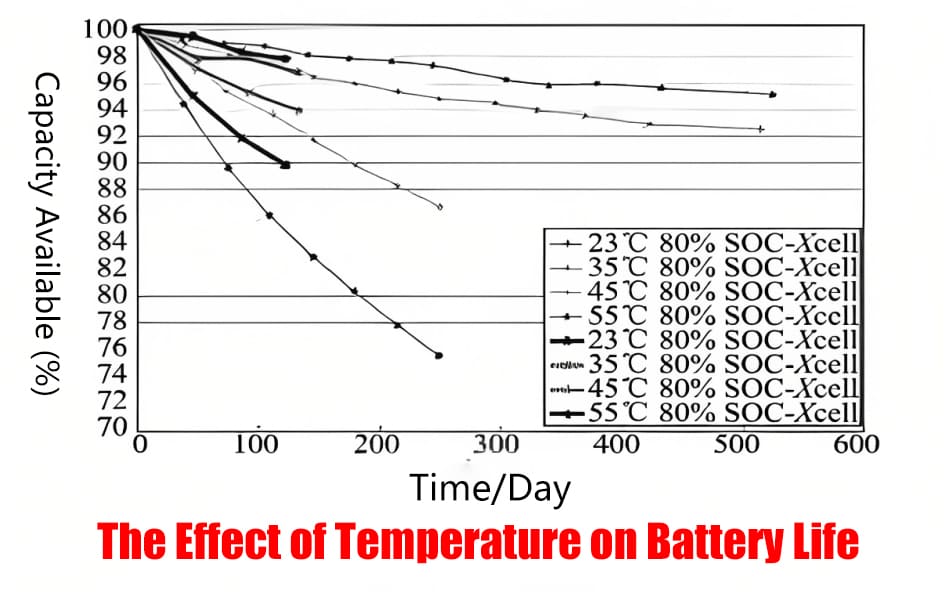

The process of releasing power from a battery is inevitably accompanied by the release of heat. The optimal operating temperature for batteries is 20° to 40°, and if this temperature is exceeded, not only will the performance of the battery will be reduced, but the driving range and the life of the battery will be drastically reduced. More serious, it may also affect the surrounding equipment, causing the consequences of combustion and explosion. This is where battery cooling technology comes in.

| 80% Remaining Capacity - Time Relationship | |

| Temperature (°C) | Lifespan (days) |

| 23 | 6238 |

| 35 | 1790 |

| 45 | 670 |

| 55 | 272 |

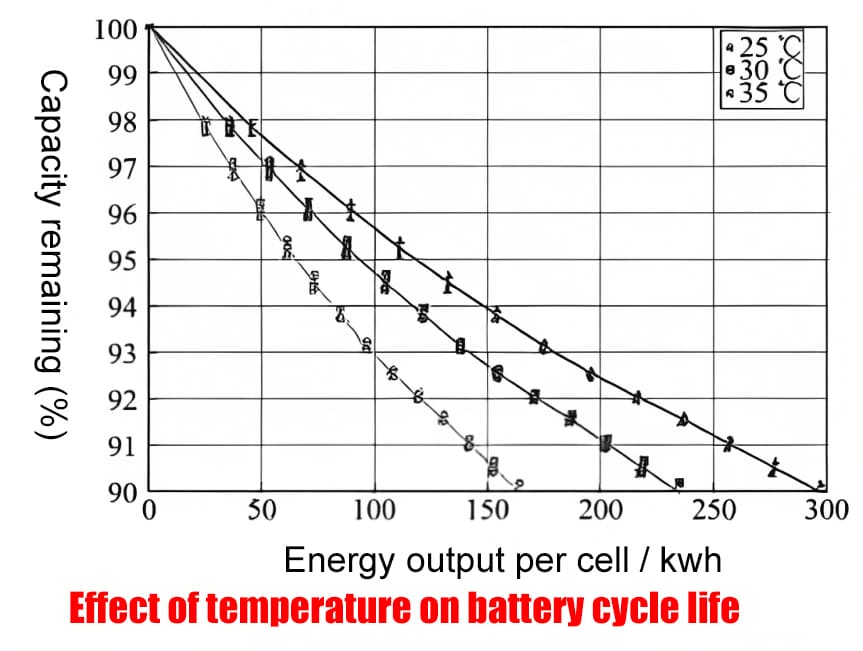

| 90% Remaining Capacity - Energy Output | |

| Temperature (°C) | Capacity output (kwh) |

| 25 | 300 |

| 30 | 235 |

| 35 | 163 |

Traditionally, air has been used to remove the heat. The heat is actually blown away. An air cooling system requires an air circulation system with ducts and vents, a fan unit to move the air, and a chiller unit to cool the heated air before it is returned to the circulation.

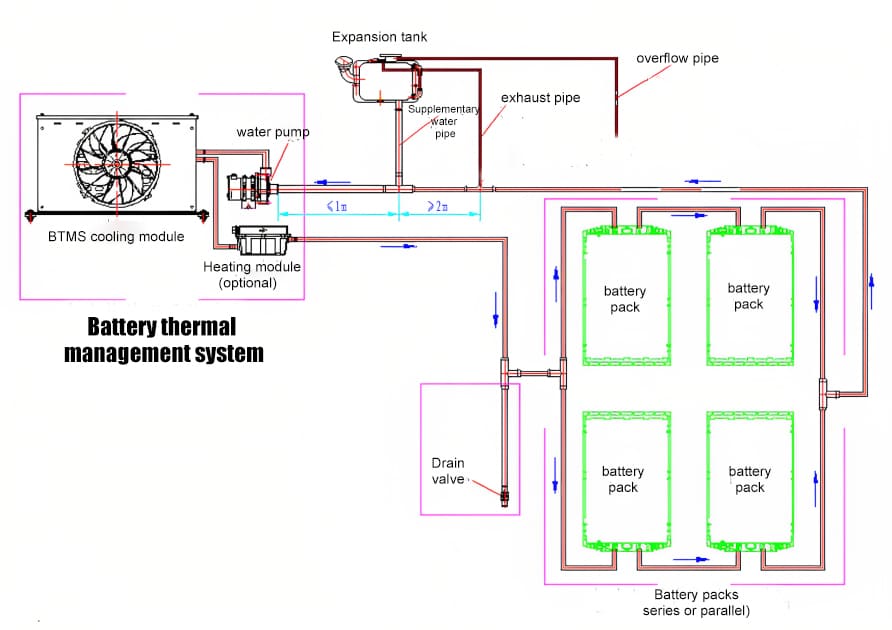

Another, better way to remove heat is to use a coolant cooling. The process here is also simple. The heat source has a radiator or a component that can be cooled with liquid. Cold liquid is circulated to the heat source and the heated liquid is pumped out and cooled with a water-to-water heat exchanger or a water-to-air cooler. A liquid cooling system requires a piping system, pumping station and a water-water heat exchanger or water-air cooler unit.

Schematic diagram of BTMS

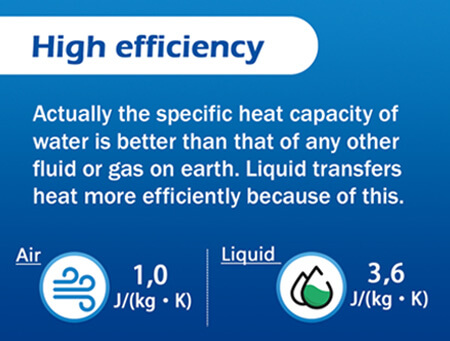

High efficiency - Actually the specific heat capacity of water is better than that of any other fluid or gas on earth. liquid transfers heat more efficiently because of this.

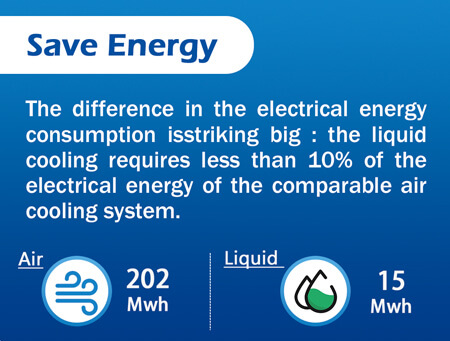

Save Energy - The difference in the electrical energy consumption isstriking big: the liquid cooling requires less than 10% ofthe electrical energy of the comparable air cooling system!

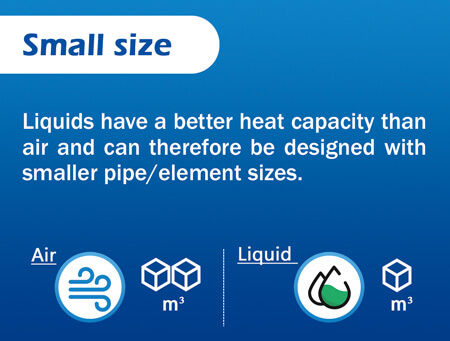

Small size - Liquids have a better heat capacity than air and can therefore be designed with smaller pipe/element sizes.

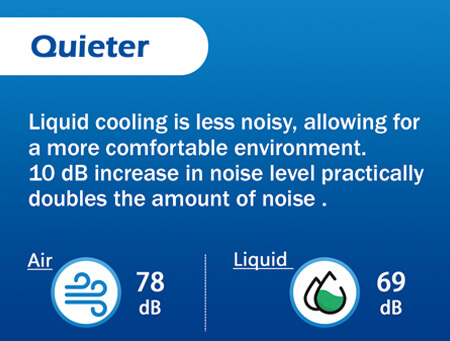

Quieter - Liquid cooling is less noisy, allowing for a more comfortable environment.

PS. 10 db increase in noise level practically doubles the amount of noise !

TKT specializes in battery chiller for electric buses and electric trucks. We has been researching and designing battery cooling technology since 2012. With 10 years of manufacturing experience, supporting OEM&OEM. With this technology, electric buses and electric trucks can travel farther with the same battery pack. The operation of the equipment is safer and more stable.

Over the past 10 years, TKT has designed and manufactured Battery Pack Cooling System according to the requirements of different OEM customers. Such as BYD, Yutong and Golden Dragon in China, and TATA Motors in India, Daewoo in Korea and other overseas markets. The cooling capacity and heating capacity of Battery Thermal Management System(BTMS) ranges from 3-10KW according to customer's requirements. We can meet the requirements of different commercial vehicles even if the ambient temperature reaches 60 degrees C or -20 degrees C. TKT also makes roof-mounted Battery Chiller, side-mounted Battery Chiller and chassis-mounted Battery Chiller according to the requirements of different customers.

Cooling System for Battery Pack - 3S Click to learn more

Cooling System for Battery Pack- 3R Click to learn more

Cooling System for Battery Pack - 5S Click to learn more

Cooling System for Battery Pack - 5R Click to learn more

Cooling System for Battery Pack - 8S Click to learn more

Cooling System for Battery Pack - 8R Click to learn more

Please feel free to leave a message Email:md@tkt-hvac.com and let our experts provide you with expert advice. We support OEM customisation.