Specially designed for heavy equipment BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 8KW / 5KW / 3KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

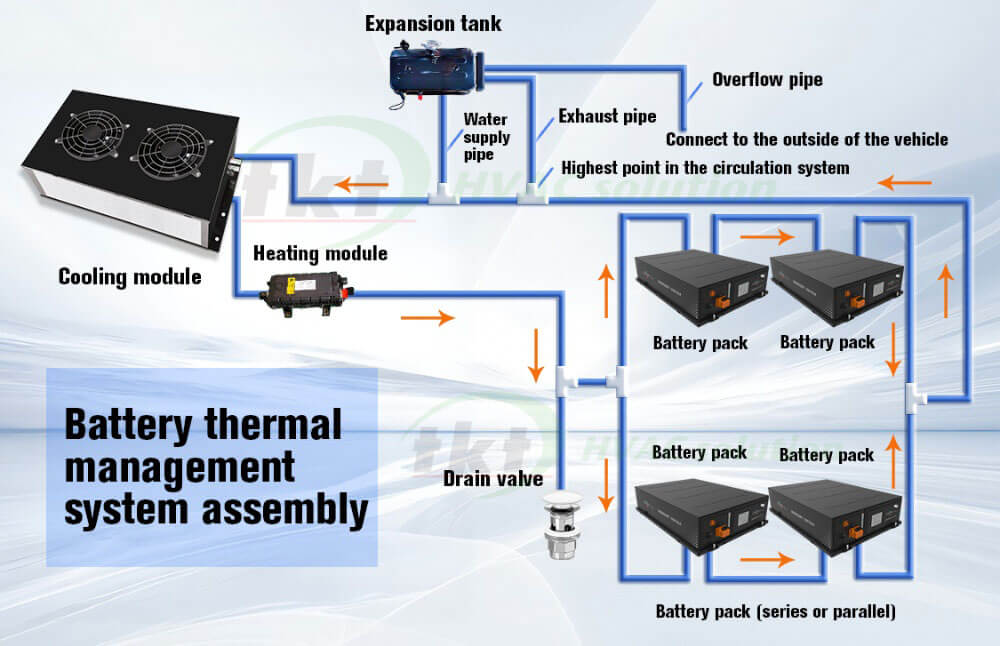

Heavy equipment typically refers to construction machinery and mining equipment, which operate in harsh environments such as high temperatures, high vibration, and high dust levels. The electric heavy equipment BTMS (Battery Thermal Management System) is a specialized temperature control system that cools and heats the power batteries in these devices. Batteries operating within the appropriate temperature range can achieve their maximum performance, extend their lifespan, and prevent thermal runaway in heavy equipment, making it safer.

Batteries in electric heavy equipment typically have capacities ranging from 300 to 600 kWh, or even 700 kWh. These batteries experience higher instantaneous charge and discharge currents, generating more heat and placing more stringent heat dissipation requirements. Therefore, the heavy equipment BTMS requires a robust heat dissipation design to withstand extreme temperatures. To meet these demands, the battery cooling system must utilize liquid cooling, which is currently the most mature and economical battery cooling method.

1. High Temperature: Battery temperatures can soar above 85°C (e.g., in desert mining areas) during continuous exposure to sunlight or high-load operation.

2. High Vibration and Shock: When operating or traveling on rough terrain, construction machinery experiences vibrations up to 20-50Hz, making traditional liquid cooling pipes susceptible to loosening or leakage.

3. High Dust and Corrosive Environments: Mine dust can easily clog heat dissipation channels, and salt spray corrosion (e.g., in coastal operations) can corrode metal components, degrading insulation performance.

4. Instantaneous High-Power Charging and Discharging: When electric mining trucks climb slopes or start under heavy load, instantaneous currents can reach hundreds of amperes, generating tens of kilowatts of heat from the batteries. Traditional battery air cooling systems struggle to meet these requirements.

| Model | 10CW | 8R | 5CW | 3R |

| Cooling Capacity | 10KW | 8KW | 5KW | 3KW |

| Standard Dimensions | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 587*355*242mm |

| Standard Weight | 40kg | 40kg | 30kg | 25kg |

| Air Outlet Direction | Side | Top | Side | Top |

Contact us to get the BTMS PDF

TKT was founded in 1998. We possess extensive battery thermal management system design experience and manufacturing capabilities. In 2018, we partnered with TATA Motors, a Fortune 500 company, to develop a custom BTMS. After undergoing multiple rounds of rigorous testing, our product received recognition and praise. Shortly thereafter, we entered into a second collaboration with them on a BTMS for electric trucks.

BTMS and BMS for electric heavy equipment are the two core subsystems of the battery system. They achieve comprehensive battery management through data sharing and collaborative control.

1. Data Sharing: The BMS transmits battery parameters such as SOC, SOH, and charge and discharge currents to the BTMS in real time. The BTMS dynamically adjusts cooling and heating power based on this data.

2. Collaborative Control: When the BMS detects an overheating alarm, it immediately initiates forced cooling. If it predicts a low temperature, it initiates preheating. Conversely, if the BTMS detects a cooling system failure, it automatically limits charge and discharge power to prevent battery overheating. They work together to ensure equipment safety and avoid the terrible phenomenon of thermal runaway.

1. “Battery Thermal Management System for Electric Vehicles and Battery Life” Click here to view

2. “Analysis of Battery Cooling System For Electric Bus, Truck” Click here to view

3. “Battery Liquid Cooling System – How Does It Work?” Click here to view

4. “BYD K9 Project: EV Battery Cooling System Combined with Bus A/C” Click here to view

5. “BTMS Battery: Principle, Design, Installation – TKT HVAC” Click here to view

6. “Battery Thermal Management System for Truck / Bus etc. – Supplied to Top 500 TATA” Click here to view

7. “Battery Thermal Management System for Switch Mobility – TKT” Click here to view

8. “Custom Battery Thermal Management System (BTMS) – TKT HVAC” Click here to view

9. “How to Design Bus BTMS Installation Location” Click here to view

10. “Battery Cooling | Battery Thermal Management System – TKT” Click here to view

Click to browse BTMS solutions for electric buses

Click to browse BTMS solutions for electric trucks

Click to browse BTMS solutions for electric heavy equipment

Click to browse BTMS solutions for electric marine

Click to browse OEM customized BTMS solutions

This article will use some failed cases to illustrate the risks of EV charging station investment. Don’t miss it if you’re interested!

Understand the 60kW EV Charger: Your Preferred Choice for Fast and Efficient EV Charging Solutions. TKT is a professional manufacturer.

The electric three wheeler rickshaw has become the best choice for short-distance commuting in cities and rural areas.