Specially designed for electric truck BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 5KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

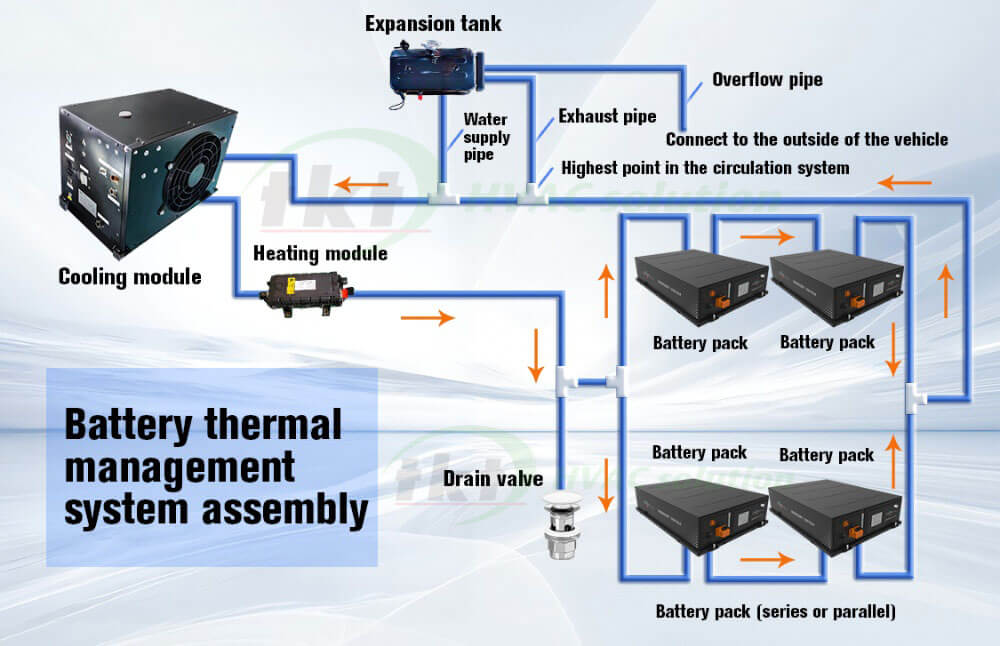

Electric truck BTMS stands for Battery Thermal Management System for electric trucks. It is a battery temperature control system designed specifically for electric trucks. This system cools or heats the battery pack to ensure it operates within the optimal temperature range, thereby improving performance, safety, and lifespan.

Cooling Cycle Operating Principle: An electronic water pump drives coolant through the cooling plates or liquid cooling pipes within the battery pack, absorbing heat generated by the battery. The high-temperature coolant is then transported to a plate heat exchanger, where it undergoes heat exchange with the refrigerant. The cooled coolant is then recirculated back to the battery.

Purpose of the Cooling Cycle: To rapidly cool the battery during high-power charging or discharging, preventing overheating and thermal runaway.

Heating Mode Circulation Principle: The refrigeration circuit is shut off, and the PTC heater is activated to directly heat the coolant. The high-temperature coolant transfers heat to the battery pack via pipes, ensuring normal battery operation in low-temperature conditions.

Purpose of the heating mode cycle: To enhance battery chemical activity in low-temperature environments using PTC heating, preventing range degradation.

Principle of the temperature equalisation mode: Multiple temperature sensors continuously monitor the temperature of each cell within the battery pack. The control system dynamically adjusts the coolant flow rate and cooling/heating power to reduce temperature differences between cells.

Purpose of the temperature equalisation mode: To reduce temperature differences between battery cells, prevent local overheating or overcooling, and extend battery lifespan.

| Model | 10CW | 5CW |

| Cooling Capacity | 10KW | 5KW |

| Standard Dimensions | 780*430*380mm | 620*350*414.5mm |

| Standard Weight | 40kg | 30kg |

| Air Outlet Direction | Side | Side |

Contact us to get the BTMS PDF

This marks the second collaboration following our initial partnership in 2018 for the electric bus BTMS project. This project focuses on the light-duty electric truck BTMS. It reflects the trust placed in us by TATA Motors, a Fortune Global 500 company, and serves as recognition of our design capabilities, product quality, and after-sales support.

Firstly, the core objectives of these two BTMS systems are consistent. Both aim to ensure that lithium-ion batteries operate within their optimal temperature range to prevent thermal runaway, maximise battery performance, extend battery life, and maintain vehicle range.

1. Cooling capacity

Electric truck battery packs are massive, with capacities typically five to ten times larger than those of passenger vehicles. This results in significant total heat generation. Additionally, heavy trucks require extremely high instantaneous power, such as during acceleration or hill climbing. Therefore, electric truck BTMS must be exceptionally well-designed to handle the extreme heat generated during heavy loads, high-speed driving, or rapid charging. The cooling system’s flow rate, heat exchange area, and radiator size all need to be significantly increased.

In contrast, electric passenger vehicles have relatively smaller battery packs and lower power requirements. Typically, a single cooling circuit or battery air cooling system is sufficient.

2. System Complexity and Cost

Electric truck BTMS have stringent cooling capacity requirements. The massive heat dissipation demands necessitate larger water pumps, compressors, heat exchangers, more coolant, and more complex piping. The system design complexity is higher, resulting in significantly higher costs compared to passenger vehicles.

Conventional electric vehicle systems are relatively simple, resulting in lower costs.

In summary, the BTMS for electric trucks is a more specialised solution designed to handle extreme thermal loads with stringent performance requirements. In contrast, the BTMS for passenger vehicles focuses on providing thermal management performance that meets daily needs within limited space and cost constraints.

1. “Battery Thermal Management System for Electric Vehicles and Battery Life” Click here to view

2. “Analysis of Battery Cooling System For Electric Bus, Truck” Click here to view

3. “Battery Liquid Cooling System – How Does It Work?” Click here to view

4. “BYD K9 Project: EV Battery Cooling System Combined with Bus A/C” Click here to view

5. “BTMS Battery: Principle, Design, Installation – TKT HVAC” Click here to view

6. “Battery Thermal Management System for Truck / Bus etc. – Supplied to Top 500 TATA” Click here to view

7. “Battery Thermal Management System for Switch Mobility – TKT” Click here to view

8. “Custom Battery Thermal Management System (BTMS) – TKT HVAC” Click here to view

9. “How to Design Bus BTMS Installation Location” Click here to view

10. “Battery Cooling | Battery Thermal Management System – TKT” Click here to view

Click to browse BTMS solutions for electric buses

Click to browse BTMS solutions for electric trucks

Click to browse BTMS solutions for electric heavy equipment

Click to browse BTMS solutions for electric marine

Click to browse OEM customized BTMS solutions

This article will use some failed cases to illustrate the risks of EV charging station investment. Don’t miss it if you’re interested!

Understand the 60kW EV Charger: Your Preferred Choice for Fast and Efficient EV Charging Solutions. TKT is a professional manufacturer.

The electric three wheeler rickshaw has become the best choice for short-distance commuting in cities and rural areas.