Specially designed for electric bus BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 8KW / 5KW / 3KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

BTMS stands for Battery Thermal Management System. The electric bus BTMS is a core system specifically designed to regulate the temperature of the electric bus’s power battery. It ensures the battery operates within a safe and efficient temperature range to improve performance, extend lifespan, and avoid thermal runaway. Electric bus BTMS utilizes large-capacity power batteries, generating significant heat. Therefore, liquid battery cooling systems are currently used.

TKT’s electric bus BTMS is fully automated. It communicates with the vehicle controller and battery management system via the CAN bus, synchronizing battery temperature data in real time and adjusting operating frequency.

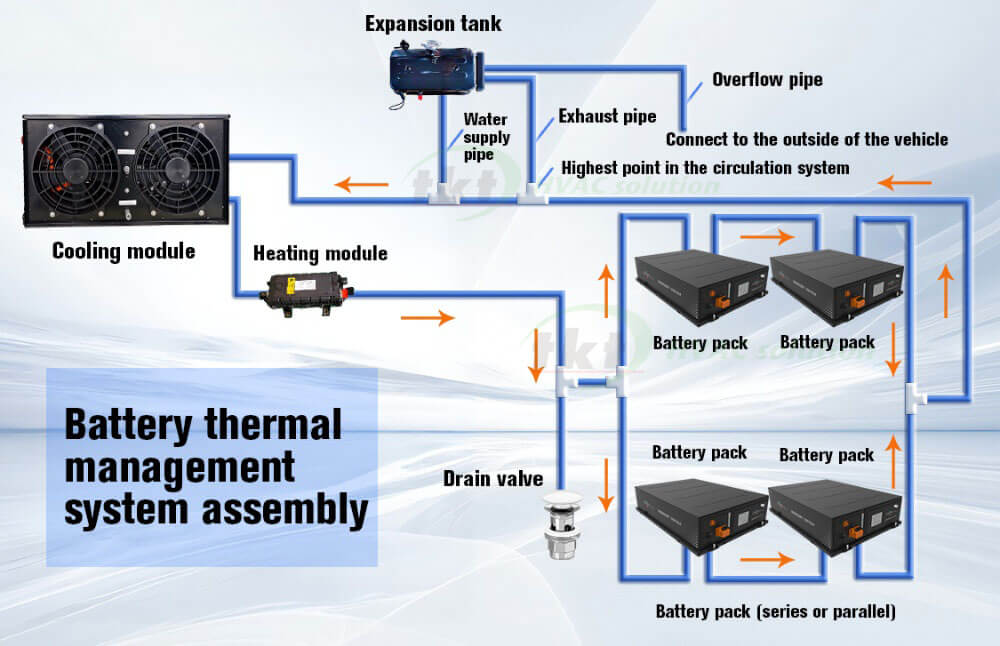

The BTMS system for electric buses typically includes cooling, heating, cooling, and electrical systems.

1. The cooling system consists of a compressor, condenser, plate heat exchanger, and water pump. It circulates the coolant to cool the battery.

2. The heating system uses a PTC water heater to heat the circulating fluid and warm the battery.

3. The cooling system includes an air-cooled radiator tank.

4. The electrical system includes the controller and wiring harness.

| Model | 10CW | 8R | 5CW | 3R |

| Cooling Capacity | 10KW | 8KW | 5KW | 3KW |

| Standard Dimensions | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 587*355*242mm |

| Standard Weight | 40kg | 40kg | 30kg | 25kg |

| Air Outlet Direction | Side | Top | Side | Top |

Contact us to get the BTMS PDF

As early as 2018, we established a deep partnership with TATA Motors, a Fortune 500 company. We custom-developed a 9m electric bus air conditioner and electric bus BTMS. After undergoing multiple rounds of rigorous testing, we became their designated supplier of electric bus air conditioners and BTMS.

Subsequently, TATA Motors initiated another collaboration project with us for the BTMS system of electric trucks. These collaborations serve as a testament to our design capabilities, product quality, and after-sales support.

Click to view more cooperation case pictures

Advantages

1. Efficient Heat Dissipation

The liquid has high thermal conductivity, quickly dissipating the large amounts of heat generated during charging and discharging. It is particularly suitable for high-temperature environments and large-capacity power batteries.

2. Excellent Temperature Uniformity

The battery cooling plate design provides a large contact area between the liquid and the battery, reducing local hot spots. This allows for precise control of inter-battery temperature differences and minimizes temperature differences.

Disadvantages

1. High System Complexity

Requires integration of components such as water pumps, piping, and seals, increasing weight.

2. High Cost

Requires more components, a more sophisticated design, and more complex assembly than air cooling.

Advantages:

1. Simple and Reliable Structure

No liquid circulation system is required; air flow is driven solely by a fan. Suitable for small battery packs or auxiliary cooling scenarios.

2. Low Cost

Lower production costs and no liquid replacement costs.

Disadvantages:

1. Low heat dissipation efficiency.

Poor air thermal conductivity makes it difficult to control battery temperature in high-temperature environments (e.g., above 45°C), which can easily lead to thermal runaway.

2. Poor temperature consistency.

Improper air duct design can result in temperature differences of more than 10°C between battery modules, affecting battery life and safety.

In summary, the high-voltage power batteries in electric buses generate significant energy and heat, necessitating a liquid battery cooling system. Air cooling systems cannot meet these cooling requirements.

1. “Battery Thermal Management System for Electric Vehicles and Battery Life” Click here to view

2. “Analysis of Battery Cooling System For Electric Bus, Truck” Click here to view

3. “Battery Liquid Cooling System – How Does It Work?” Click here to view

4. “BYD K9 Project: EV Battery Cooling System Combined with Bus A/C” Click here to view

5. “BTMS Battery: Principle, Design, Installation – TKT HVAC” Click here to view

6. “Battery Thermal Management System for Truck / Bus etc. – Supplied to Top 500 TATA” Click here to view

7. “Battery Thermal Management System for Switch Mobility – TKT” Click here to view

8. “Custom Battery Thermal Management System (BTMS) – TKT HVAC” Click here to view

9. “How to Design Bus BTMS Installation Location” Click here to view

10. “Battery Cooling | Battery Thermal Management System – TKT” Click here to view

Click to browse BTMS solutions for electric buses

Click to browse BTMS solutions for electric trucks

Click to browse BTMS solutions for electric heavy equipment

Click to browse BTMS solutions for electric marine

Click to browse OEM customized BTMS solutions

This article will use some failed cases to illustrate the risks of EV charging station investment. Don’t miss it if you’re interested!

Understand the 60kW EV Charger: Your Preferred Choice for Fast and Efficient EV Charging Solutions. TKT is a professional manufacturer.

The electric three wheeler rickshaw has become the best choice for short-distance commuting in cities and rural areas.