This article introduces the following contents in detail: Types of electric bus charging station, BYD Olectra project cases, electric bus charging time, charging station location recommendations, and how to maintain them?

Currently, there are two mainstream methods for charging electric buses. They are Pantograph Charging and Plug-in charging.

Pantograph Charging is a charging method specially designed for electric buses. This charging equipment automatically connects to the charging interface on the top of the electric bus through a professional robotic arm, and then transmits electric energy.

Specific steps: When an electric bus enters the charging area, the charging device will automatically identify and locate the charging interface on the top of the bus. The robotic arm will then move precisely to ensure perfect docking with the charging port. Once the docking is successful, Pantograph Charging can start charging the battery of the electric bus.

Solutions for Automotive Manufacturers

The main advantages of this electric bus charging station solution are automation, efficiency and safety.

1. Automation: This solution does not require manual operation, the system will automatically recognize the signal, start and end.

2. Efficiency: It can quickly and accurately connect to the charging interface of the electric bus, reducing preparation time and improving charging efficiency.

3. Safety: Since the charging process is automated and the equipment is designed with safety factors in mind, such as preventing electric shock and overheating, this method is highly safe for both people and equipment.

The disadvantages of this electric bus charging solution are high cost, difficulty in construction, and small scope of application.

1. High cost: Because it is an advanced automation system, the cost of charging equipment, charging station construction and later maintenance is higher than that of ordinary DC charging stations.

2. Difficulty in construction: This kind of charging equipment has a special installation method, so it has high requirements on the layout and space of the charging station.

3. Small scope of application: This charging method is only suitable for large electric buses.

Plug-in charging, which is the ordinary DC charging method. It first obtains AC power from the power grid, and then converts the AC power into DC power through an internal inverter. This DC power is then delivered to the battery of the electric bus for rapid charging.

Specific steps: The staff accurately inserts the connector of the DC charger into the electric bus. Then use the charging card to set the time or power of the charger. Finally turn on charging.

TKT Electric Bus Charging Station in China

Compared with Pantograph Charging, its advantages are that the cost is relatively low, the construction of charging stations is less difficult, and the scope of application is wider. Almost all electric buses can be used. There is no need to distinguish between specific bus makes and models. Therefore this charging method is the most common fast charging method for electric buses.

This project is our cooperation with BYD Olectra, a famous Indian electric bus manufacturer. The number of charging stations in the first batch exceeds hundreds. In this project we are honored to work with Dinesh Navgire from Olectra. He is an electrical engineer with extensive experience and professional skills. He focuses on the operation and maintenance of electric bus charging infrastructure. He has efficient solutions for the maintenance and management of EV charging infrastructure, which can ensure the stable operation and efficient use of charging facilities. Our collaboration focuses on improving the performance and experience of EV charging stations. He worked closely with our team to ensure the smooth progress of the project, demonstrating excellent professionalism and teamwork.

Electrical engineer installs and commissions electric bus charger

Here, we share a photo of Mr. Dinesh in front of the charging station. This group photo symbolizes his support and recognition of our project. We look forward to working with Olectra to bring innovation and improvements to public transportation systems across India. We believe that through our joint efforts, we can create a greener and more efficient future for the earth.

Trusted by Fortune 500 Customers

| Power | 180kW Level 3 electric bus charging station | |||

| Input Voltage | 3-Phase 400V/440V/480V+15% AC | |||

| Working Frequency | 45~65Hz | |||

| Power Factor | ≥0.99 | |||

| Efficiency | ≥94% | |||

| Rated Voltage | 1000Vdc | |||

| Max. Output Current | 250A | |||

| Display | 8” LCD Touchscreen | |||

| Language | Chinese, English, Russian, Other languages support customization | |||

| Payment | Mobile APP/RFID | |||

| Network Connection | 4G / Ethernet | |||

| Communication Protocols | OCPP1.6J | |||

| Working Temperature | -30°C ~ +50°C | |||

| Storage Temperature | -35°C ~ +55°C | |||

| Protection | IP54 | |||

| Cable Length | 5m/7m | |||

| Certificate | ISO9001, IATF16949, NTC CE, IEC61851-1, IEC61851-23, IEC61851-21-2, etc. | |||

| View this product page Two outlet | 80kW- 200kW | ||||

First, you need to know what the battery capacity of your electric bus is. The battery capacity of electric buses varies depending on the model, manufacturer and design requirements. Let me take the BYD K9 electric bus as an example. Its battery capacity is 324kWh.

1. If you buy our best-selling 180kw EV DC charger. Approximate charging time is 113 minutes.

2. If you charge two electric buses at the same time, the approximate full charging time is 226 minutes.

Our dynamic load balancing function intelligently allocates charging power based on the electric bus’s battery model, remaining power, etc. It can achieve the shortest overall charging time.

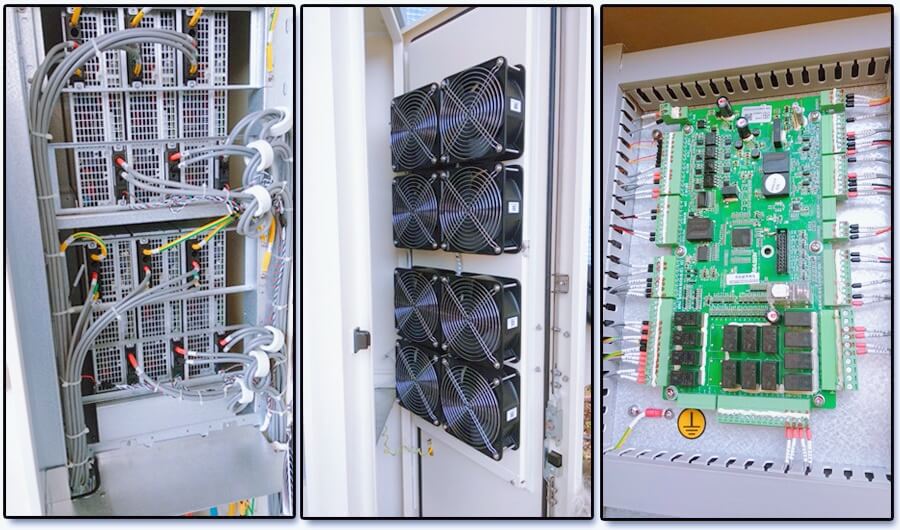

TKT electric bus charger factory

The power of the electric bus charger you should choose depends on comprehensive factors such as the daily operation history, frequency, and parking time of each vehicle. This helps maximize profits. If you still don’t know how to choose, please feel free to consult our expert advice. Email: md@tkt-hvac.com

Common DC charger connectors are CCS1, CCS2, CHAdeMO, and GBT.

In order to feel the connector more realistically, we made this picture. This picture shows what a charging connector looks like and what a socket on an electric vehicle looks like. I believe you can tell the difference if you look carefully.

When planning and laying out electric bus charging stations, there are three most important aspects to pay attention to:

1. Geographical location: It is recommended that charging stations be located near road sections where electric buses frequently pass or intersect. This reduces bus travel distance and charging time. Secondly, it can also improve the utilization rate of charging stations and reduce idle time.

2. Power resources and grid access: Charging stations need stable and sufficient power supply. Therefore, the convenience and stability of grid access need to be considered when selecting a site.

3. Safety factors and environmental protection: The construction and operation of EV charging stations require strict compliance with safety regulations, including lightning protection, fire protection, waterproofing and other measures. At the same time, environmental protection factors must also be considered, and environmentally friendly building materials and equipment must be selected to reduce the impact of charging stations on the surrounding environment.

Maintenance of electric bus charging infrastructure involves many aspects, which is beneficial to its normal operation and extended service life.

✔Check whether the charging connector and charging cable are intact.

✔Check whether the display screen and indicator light of the EV charger are normal.

✔Check for any unusual sounds or smells.

The periodic maintenance cycle of the DC charging station is recommended to be carried out at least once a year. However, due to differences in equipment usage frequency, environmental conditions, etc., comprehensive considerations are required.

✔Inspect and test charging modules, control units, communication modules, etc. to ensure their performance is stable and reliable.

✔Check whether the power supply and communication line connections of the charging station are normal to prevent loosening or breakage.

✔Check whether the electrical components and wiring inside the charger are intact and whether they are aged or damaged.

✔Check the grounding condition of the charger to ensure it is safe and reliable.

✔Test charger for overcurrent, overvoltage, undervoltage and other protection functions to ensure they are normal and effective.

✔Conduct lightning protection and anti-static tests regularly to prevent damage to equipment due to lightning or static electricity.

TKT is China's leading electric bus charger manufacturers. TKT factory occupies nearly 10,000 square meters and we are committed to providing quality and reliable charging station solutions. We control every step of the process, from design to manufacturing. In addition, we support customized EV chargers.

Email: md@tkt-hvac.com

WhatsApp: +86 13015505615

Facebook: https://www.facebook.com/TKTHVAC/

linkedin: https://www.linkedin.com/company/tkt-hvac

YouTube: https://www.youtube.com/@TKTHVAC