TKT HVAC has 24 years of experience as bus air conditioner manufacturers. TKT believes that higher quality air conditioners can reduce after-sales problems, which is the best protection for customers. Therefore, our quality inspection process has very high standards, and the experience requirements for our inspectors are also very high. These are all helpful for bus air conditioning troubleshooting.

Article Main Chapters: TKT Quality Inspection-Internal Inspection, TKT quality inspection-external inspection, TKT quality inspection-operation inspection, TKT Quality Inspection-Packaging Inspection, Important certifications for bus air conditioners, Fortune 500 BYD/TATA cooperation case.

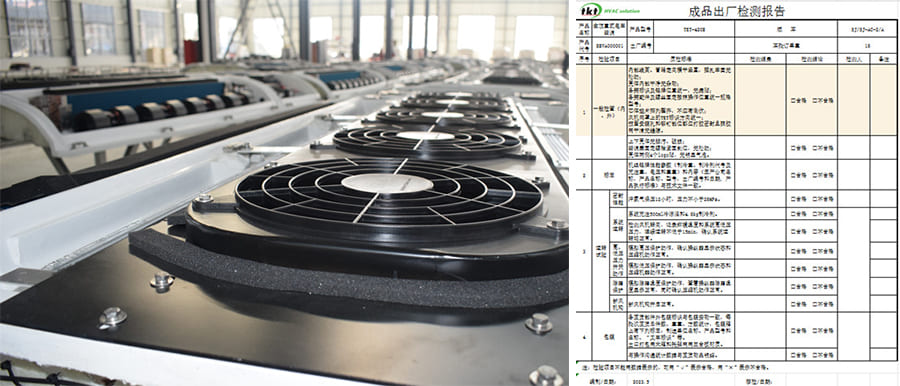

Bus A/C detail and quality inspection process table 1

We will be responsible for factory inspection of every TKT A/C machine. To ensure the high performance and stable operation of each bus air conditioner. TKT experienced quality inspectors will complete dozens of qualification tests. They meticulous and strict testing can reduce many quality hazards and greatly improve the probability of bus air conditioning troubleshooting.

The internal structure of the air conditioner is very complex and requires a lot of inspection content. The content listed below are just some part.

1. The requirements for pipeline harnesses are that the internal wiring harness and pipelines run horizontally and vertically, and are bundled firmly without looseness. This looks clean and tidy, and it is very easy to quickly find the corresponding location if there is a fault in the future.

2. The positions of various signs and nameplates are unified, and the content is clear and clear. Detailed identification can help customers clearly understand the corresponding component location, voltage and other information to avoid misoperation.

3. The core fins are neatly arranged and not broken or messy. Neat arrangement helps increase the heat exchange area, achieve higher heat exchange efficiency, better remove heat, and improve cooling effect.

1. The upper and lower shells are not dirty or damaged. A good product image increases customers' trust and favor.

2. The fixing bolts of the air conditioner cover are tightened in place without looseness. Ensure product safety during transportation, without bumps or damage.

3. There are 4 logo stickers on both sides of the shell, with no obvious bubbles. The requirement of detail quality is brand image.

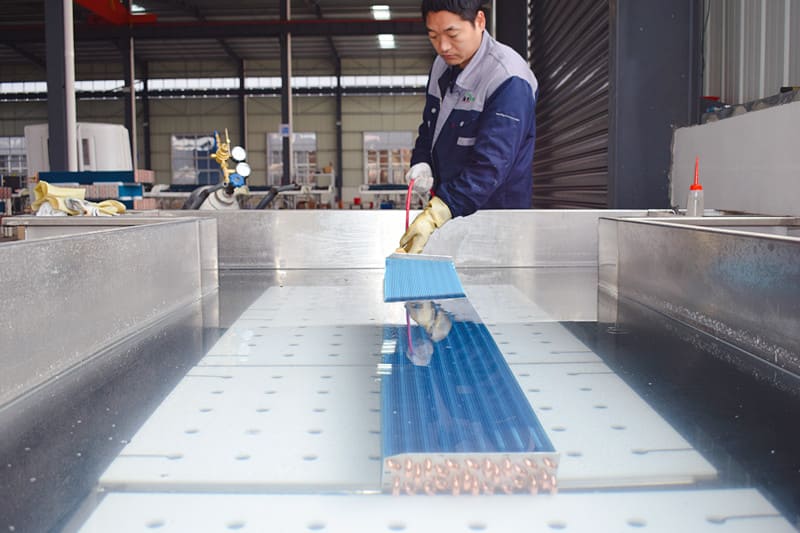

1. Sealing performance inspection. Flush with nitrogen and perform a continuous pressure test for 12 hours, with the pressure not less than 28MPa. The evaporator core, condenser core, and pipes all need to be inspected.

2. Operation inspection of the bus air conditioning system. First charge the system with refrigeration oil and refrigerant. Then detect the fan rotation and record the ambient temperature, outlet air temperature, system high and low pressure, etc. In order to ensure system stability, the air conditioner will run continuously for no less than 30 minutes to confirm that the system is operating normally.

3. High and low pressure pressure switch action. Simulate the high-pressure protection action and confirm that the display status of the controller and the normal operation of the compressor are confirmed. Simulate the low-voltage protection action and confirm the display status of the manipulator and the normal operation of the compressor.

Exporting overseas requires a long shipping process. Therefore, stable and safe packaging is very important. Our export packaging uses special custom-made pallets.

Before shipment, our quality inspection personnel will carefully check that the outer packaging label of the shipped parts is consistent with the actual packaging. Information such as the total number of pieces, weight, square meters and other information of each batch of shipments will be carefully counted.

After more and more detailed quality checks like this, TKT Bus Air Conditioning Troubleshooting rate has increased dramatically. The shipment packaging also adopts a customized frame solution, which comprehensively ensures the high quality of the air conditioners.

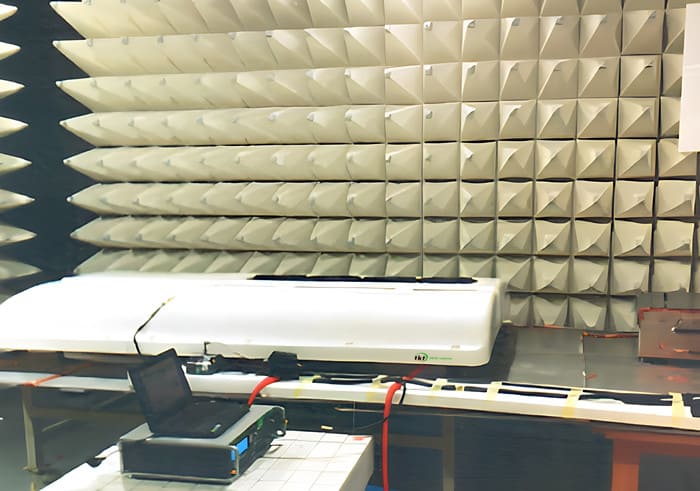

TKT HVAC has been established for more than 20 years and its products are of excellent quality. And it has passed the quality requirements and safety tests of TATA/BYD, Fortune 500 companies. You can have complete peace of mind when it comes to product quality. The following are some of the important certification inspections. (Click to view certificate)

1. EMC electromagnetic compatibility test: The comprehensive evaluation of the interference (EMI) and anti-interference ability (EMS) of the commercial vehicle air conditioner in the electromagnetic field is one of the important indicators to judge the quality of the product.

2. Rain test: TKT air conditioners are usually installed on the roof of the vehicle, and it must be ensured that it can withstand various harsh environments. TKT products have undergone strict rain testing. (Click to see the rain test details)

3. Vibration test: The vehicle air conditioner is installed on the vehicle, so it needs to be tested to simulate violent bumpy road conditions. TKT air conditioners can withstand the extremely rough road conditions in India. 5 years later, they are still running stably.

TKT not only has its own factory in China. We also have our own factory in India. And it has already cooperated with India's TATA motors in 2018. Provide them with full electric bus air conditioning. If you are very satisfied with tata bus air conditioner and looking for bus air conditioner suppliers, please contact us now. We will arrange experts to provide you with technical support and solutions.

TKT also reached cooperation with Olectra bus manufacturer this year. Provide air conditioning for electric buses, Olectra is very satisfied with the quality of our products. We were therefore also entrusted with the development of a new integrated system - A/C Combine Chiller. The new system includes the functions of the bus air conditioning and the battery thermal management system.

Bus air conditioning is used to cool down the interior of the bus and solve passenger comfort issues. The battery thermal management system is designed to cool down the battery and solve the heating problem when the power battery supplies power to the electric bus.

TKT bus air conditioning solutions are very diverse, including not only traditional bus air conditioning solutions, but also electric bus solutions, full electric double decker bus air conditioner solution and bus conversion air conditioner solution.

TKT has rich OEM customization experience and product development capabilities. With the development of buses and the pursuit of higher quality, if you need a 60k btu bus air conditioner, we can upgrade the performance. Bus manufacturers are welcome to inquire and customize.

Feel free to get expert advice by contacting us or sending an email to md@tkt-hvac.com.