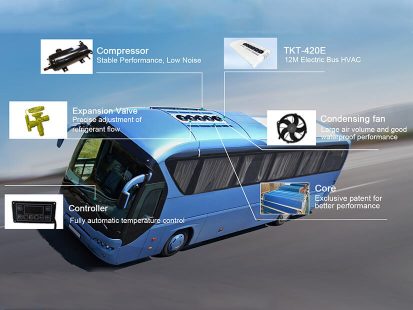

This electric bus AC model is TKT-160E. It is suitable for 6-7m electric buses, school buses, etc.

1. Cooling Capacity: 16 KW / 54K BTU

2. Electric Bus Voltage: DC 280-800V

3. Competitive Price / Heating Optional

4. Quality Trusted by BYD & TATA

5. Higher Quality: Leading Global Brand Compressor / Copper Tube and Aluminum Fin, etc.

The type of air conditioner on the current page is electric bus air conditioning. It is designed for electric buses. It requires DC 280-750 power battery for power. If your bus is engine driven. It is not suitable for this air conditioner. We offer other solutions. Based on more than 20 years of experience, this air conditioner with a cooling capacity of 54K BTU is suitable for electric buses between 6 and 7 meters.

If your bus is powered by a diesel engine, we also have diesel bus air conditioning solutions.

As an expert and leading manufacturer of Electric bus AC in China, TKT busthermo has been supplied to YUTONG, Golden Dragon, Yaxing, Ankai, Neoplan, Hengtong, Shenlong, Foton and Nanjing Golden Dragon ect main bus manufacturer in China, and also do OEM to TATA Motor, TATA Marcopolo, Daewoo, Isuzu, MAZ, INCARVEN, MODABUS, GET ect bus manufacturer in the world. Those rich experience and over 20 years of market verification prove that TKT air conditioner is trustworthy.

✔ High Cooling: TKT HVAC patented system design ensures that the bus stays cool even in tropical climates, providing super cooling for extreme conditions.

✔ High Durability: Uses branded components and copper tube aluminum fin to maintain performance and stability, guaranteeing lifetime.

✔ Environmentally Friendly: Utilizes eco-friendly materials and refrigerants to minimize environmental impact.

✔ Energy Saving: Adopts energy-saving components and optimized layout to ensure cooling effect while reducing energy consumption.

✔ Fresh Air Available: Provides fresh air options for better passenger comfort.

✔ OEM/Customized Systems: Accepts OEM/customized system requests to meet specific requirements.

Learn More About Advantages in Detail

As a veteran electric bus AC manufacturer, we are fully aware that you get what you pay for. TKT utilizes quality components to ensure that our products have superior performance and a longer lifespan. When you choose TKT Busthermo, you’re getting a reliable, top-of-the-line cooling solution.

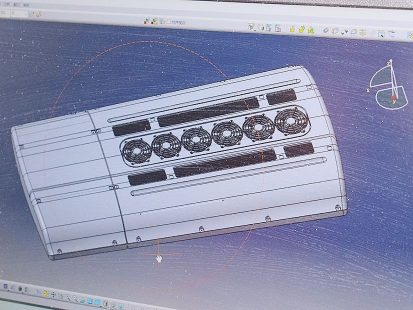

| Model | TKT-160E | |

| Cooling | 16 KW (54K BTU) | |

| Heating | Heating is Optional | |

| Control way | Digital control panel + CAN Control(optional) | |

| Application | 6M-7M EV Bus | |

| Refrigerant | R134A | |

| Compressor Voltage/Power Supply | DC280-750 V | |

| Control Voltage/Power Supply | DC24 V/8 A | |

| Electric Bus AC Compressor | Electric compressor(42 cc/r) | |

| Condenser | Coil type | Copper Tube and Aluminum Fin Structure |

| Fan Air Volume | 3600 m³/h (2 Fans) (3 fans is available, based on clients need) | |

| Evaporator | Coil type | Copper Tube and Aluminum Fin Structure |

| Fan Air Volume | 7200 m³/h (4 Fans) | |

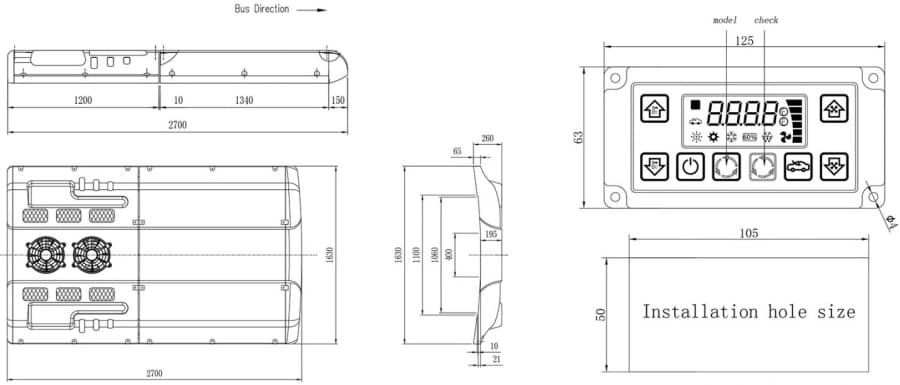

| Dimension | 2700*1630*195 mm | |

The leading bus air conditioner manufacturer in China! TKT has a team of 135 engineers. They include design engineers, structural engineers, electrical engineers, test engineers, etc. They have complete design, development, and testing capabilities for commercial vehicle air conditioners and components.

Click for More Cases (Load HD Pictures, Wait Patiently)

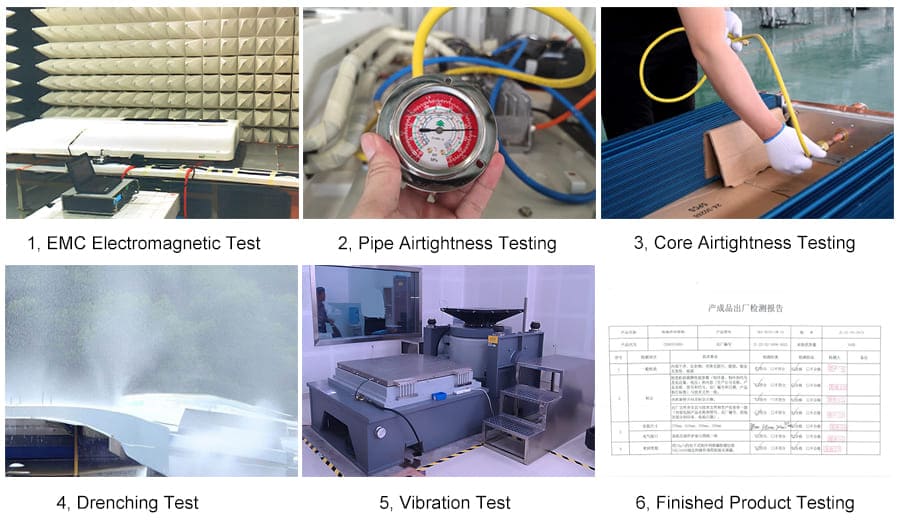

TKT HVAC has a strict quality inspection process. Such as EMC electromagnetic test, piping air tightness test, drenching test, vibration test, finished product test and so on. This is all in order for you to get reliable bus air conditioners. (Click here to view Bus Rooftop Air Conditioner quality Inspection details)

You will get the following benefits.

1. Longer lifespan: more than 30% longer than low-end air conditioners

2. More stable operation: 45 degree outdoor temperature still stable operation

3. Factory sourced pricing

4. Customized OEM service

5. (Click to learn more benefits)

1. Why Choose us?

A. Reliable quality and competitive Price

B: Professional and well trained sales, and Technical support

C: Flexible payment terms

2. What is your Warranty Policy?

Firstly, we provide 18 months warranty from the date of delivery. Free spare parts will be provided if the parts defective for quality reason during the warranty period. But videos and fault description will be need for engineer double check first! Damage or defective caused by improper use not covered by warranty.

TKT HVAC was founded in 1998. So far, it has obtained many quality certificates such as ISO9001:2015, IATF16969:2016, CE, EMI/EMC, etc. And owns more than 100 related patents.

Typically 7-10 days if in stock.

If there is no stock, it is usually in 3 weeks. Of course, the specific situation depends on the order quantity and the task of our factory.

ac for electric double decker bus, ac for full electric double decker bus, electric bus ac compressor, electric bus ac system, full electric double decker bus ac, electric double decker bus ac, roof top shutle bus ac electric.

If your bus is powered by a diesel engine, we also have diesel bus air conditioning solutions.

It introduces in detail the key parts of the bus aircon and the working principle of key part. Easy to understand and very professional.

TKT has a wealth of bus air conditioning unit solutions. This article introduces many basic knowledge and installation steps of bus A/C.

AC combine chiller project is an innovative design that integrates EV battery cooling system and electric bus air conditioning.