This article will explain in detail the bus air conditioner installed on the roof from a professional point of view. The benefits of installing it on top of a bus are revealed from a scientific point of view. What are the common classifications of bus air conditioners? And how to judge high quality Roof Mounted Bus Air Conditioning System, etc.

I summarized the 3 most important reasons.

1, Air Properties:

I believe we must have heard of hot air balloons. Why can hot air balloons float in the air? It is because the mass of hot air is lighter and the mass of cold air is heavier. Therefore, in the bus space, hot air will be more concentrated in the upper part. Therefore, the installation of the bus air conditioner on the roof will be more conducive to the discharge of hot air and will greatly enhance the cooling efficiency of the air conditioner.

2, Easy to Install, Maintenance and Repair:

Any equipment has its own use life, the bus air conditioning is no exception. If installed on the roof of the bus, either to replace the new air conditioner later, or inspection, maintenance will be more convenient, because you do not need to disassemble the main structure of the bus. It can be done directly by having a technician go to the top of the coach.

PS: High-quality coach air conditioners last longer and can reduce the cost of post-care. (This point is often overlooked)

3, Better Riding Experience:

Install the air conditioning in the top area of the bus exterior, can better reduce vibration and noise, bringing a better experience for passengers. If installed in other areas, will inevitably need to add more costs and technology to solve the problem.

If you need any advice from our experts, please feel free to email us with your questions. Email:md@tkt-hvac.com

Roof Mounted Bus Air Conditioning System, usually subdivided into engine bus air conditioning, sub-engine bus air conditioning, and electric bus air conditioning.

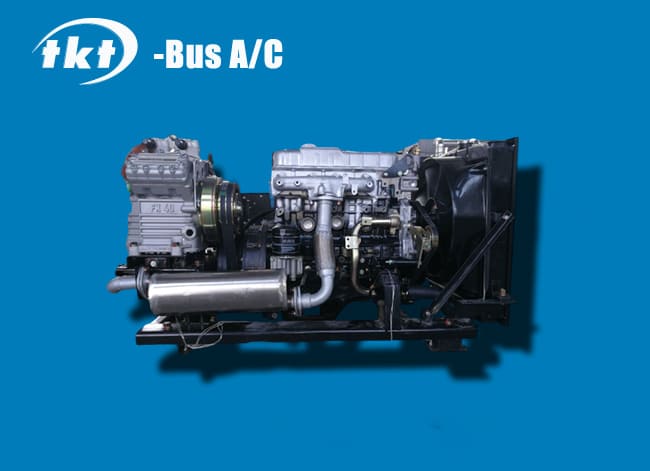

1, engine bus air conditioner:

Also known as diesel bus air conditioner or traditional bus air conditioner. Nowadays, the world's buses are still mainly diesel-driven because it is the lowest cost. All buses that rely on engine drive can use this type of bus air conditioner.

2. Sub-engine bus air conditioning:

Basically the same as engine bus air conditioning. The difference is mainly the use of slightly different scenarios. For example, the lack of power in some coach, or the need to park for a long time still running air conditioning and other situations.

3, electric bus air conditioning:

With the deterioration of the world environment, sustainable green energy bus gradually developed. Therefore, the bus air conditioner also needs to use new green energy - electric drive. This kind of air conditioner can only be installed in electric buses, which need buses with enough high-voltage batteries, usually between DC 280V-750V. (For mini buses with particularly small space, a special solution also exists that can barely use 12V/24V truck RV air conditioners)

After understanding this difference, the rest can be based on the specific length of the bus or the number of seats, to choose a different cooling capacity can be.

If you need any advice from our experts, please feel free to email us with your questions. Email:md@tkt-hvac.com

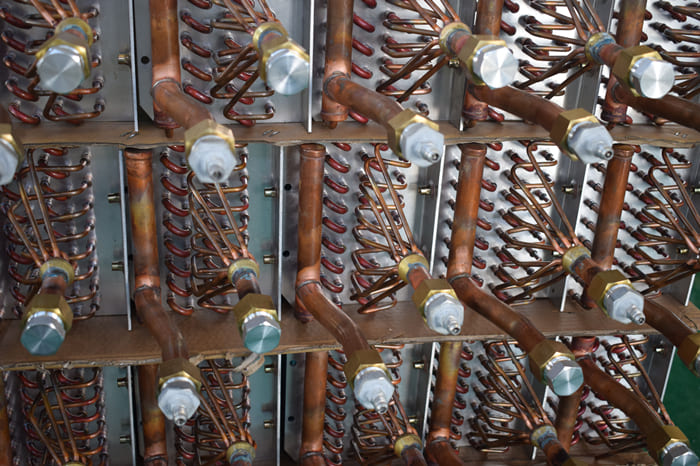

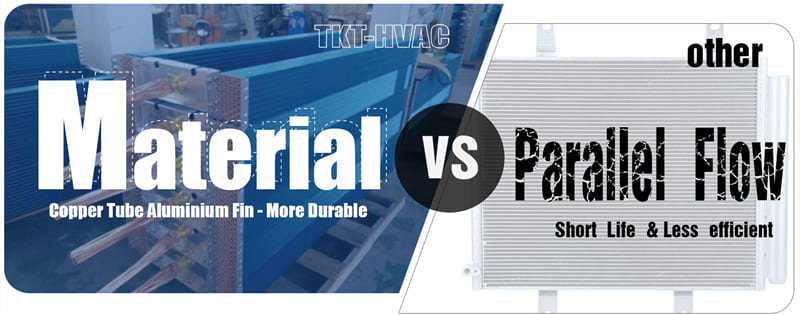

With over 20 years of experience, TKT senior engineers have continuously optimized the core design ideas and production process. Our advanced core fabrication process has controlled the copper tube spacing to 21mm (industry common spacing is 25mm), the smaller spacing can accommodate more copper tubes, which in turn increases the heat exchange efficiency by 16%. (Click on image to enlarge)

The common cores are divided into two structures: parallel flow (pure aluminum) and Cooper Tube and Aluminum Fin. In comparison, the Cooper Tube and Aluminum Fin type is better, as evidenced by the cost of the material. Details of the main advantages:

1、Higher heat dissipation efficiency

Cooper Tube and Aluminum Fin Structure is relatively more efficient in heat dissipation. Because the thermal conductivity of copper is very high, while the specific heat capacity of aluminum is small, coupled with the design of the Cooper Tube and Aluminum Fin type core uses a large contact area of copper and aluminum, so the heat can be transferred to the aluminum sheet faster, and then through the fan and other cooling equipment to dissipate, compared to the parallel flow heat exchanger relatively slow.

2、More environmental friendly and energy saving

Air conditioners with Cooper Tube and Aluminum Fin cores are able to work with lower power compressors for the same cooling capacity due to their higher cooling efficiency. This means that, under the same cooling effect, copper aluminum air conditioning will consume less electricity, with higher economy and energy efficiency.

3、More corrosion resistant

The Cooper Tube and Aluminum Fin core is composed of copper and aluminum, of which the aluminum sheet is made of high purity aluminum, and through a special process, it has better resistance to oxidation and corrosion. This means that after a period of use, the core is less likely to rust, fall off or deform, ensuring the long-term stable operation of the air conditioner.

If you need any advice from our experts, please feel free to email us with your questions. Email:md@tkt-hvac.com

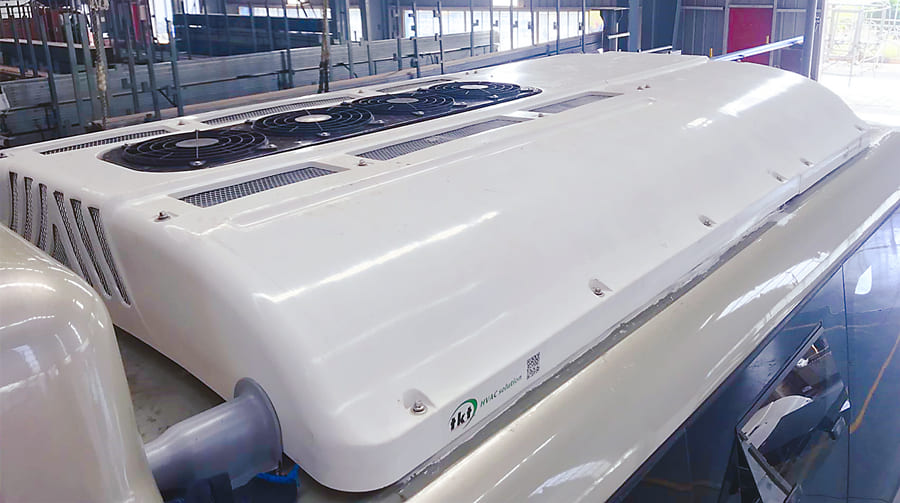

TKT bus air conditioner fan cover, using the Archimedes spiral principle and conical patent design. This design is effective, optimizing the airflow trajectory, taking away heat more quickly and greatly improving the heat exchange effect of the air conditioner. (Click on image to enlarge)

The design of the connection structure of each pipeline and part inside the air conditioner is optimized to improve the flow path of refrigerant. As a result, the heat exchange efficiency is improved, the refrigerant charge is reduced by 35%, and the refrigerant leakage is reduced. It contributes to the protection of the world environment. (Click on image to enlarge)

High thickness anti-vibration foam is added to almost every part and between parts. The sheet metal is also all thickened. It can better cope with various road conditions.

If you need any advice from our experts, please feel free to email us with your questions. Email:md@tkt-hvac.com

Material selection of high-grade iron aluminum alloy, high temperature resistance and corrosion resistance greatly enhanced. The strength is more than a little higher than ordinary aluminum alloy and plastic.

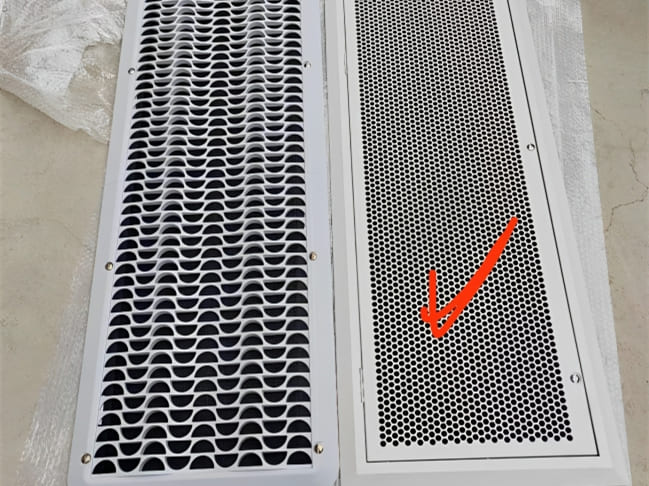

The interior adds advanced dustproof fiber and stable hexagonal grille design to ensure the freshness of air as well as heat exchange efficiency.

According to the principle of aerodynamics, senior engineers fully consider the wind resistance coefficient and wind volume requirements of the roof, and the professional streamline design.

The material chosen is FRP, which has the characteristics of light weight, high strength, corrosion resistance, insulation and beautiful appearance. It provides sufficiently high strength protection and reduces overall vehicle weight and increases vehicle mileage. Such a choice meets the need of energy saving and environmental protection, which is always the belief of our company.

We attach great importance to partnership, because only long-term and stable cooperation will lead to a win-win situation. We hope more friends can share this idea and work together to bring more coolness to people all over the world, have a good working and living environment, and at the same time work together for the sustainable development of the world.

For more information on diesel bus air conditioners.

For more information on Sub-engine bus air conditioning.

For more information on electric bus air conditioning.

If you need any advice from our experts, please feel free to email us with your questions.

Email:md@tkt-hvac.com