Battery thermal management system for electric vehicles and battery life has a direct impact on the relationship. This is because temperature control directly affects battery chemical stability and physical structural integrity. Battery degradation, i.e., decreased capacity and increased internal resistance. It is essentially the cumulative result of internal electrochemical reactions and material aging. Unsuitable temperatures accelerate this process. In this paper, we analyze the aging mechanism of battery, the effect of temperature on aging, and the principle of battery thermal management system in three dimensions.

Batteries for commercial vehicles such as electric buses are usually lithium-ion batteries. The life of lithium-ion batteries decreases mainly due to two irreversible processes.

1. Cyclic aging, i.e. caused by charge/discharge cycles. The materials of the positive and negative electrodes of the battery undergo volume changes during the embedding/de-embedding process of lithium ions, which can lead to chalking of the positive and negative electrode structures, shedding of active substances, and so on. At the same time, the electrolyte and electrode SEI film continues to grow consuming electrolyte and lithium source.

2. Storage aging, i.e., caused by long-term standing. Even without charging and discharging, “self-discharge” will still occur inside the battery. If the battery is exposed to high temperature, it will accelerate the decomposition of electrolyte and the dissolution of metal ions. That will further damage the electrode structure.

Temperature is an important variable in the aging of EV batteries. Too high or too low will significantly accelerate the degradation.

1.1 Negative Electrode Excessive Decomposition Reaction The SEI film is a key barrier to protect the electrode. High temperature accelerates the decomposition reaction of the electrolyte on the surface of the negative electrode. This will consume more electrolyte and active lithium, leading to irreversible capacity loss. Experimental data shows that the capacity retention rate for 1000 cycles at 25°C is about 85%, compared to only 60% at 55°C. Data source: Journal of Power Sources.

1.2 Structural damage of cathode material. Nickel-cobalt-manganese/nickel-cobalt-aluminum cathode is prone to “transformation from layered structure to rock salt structure” at high temperature. This process reduces the lithium embedded capacity of the material and accelerates capacity decay.

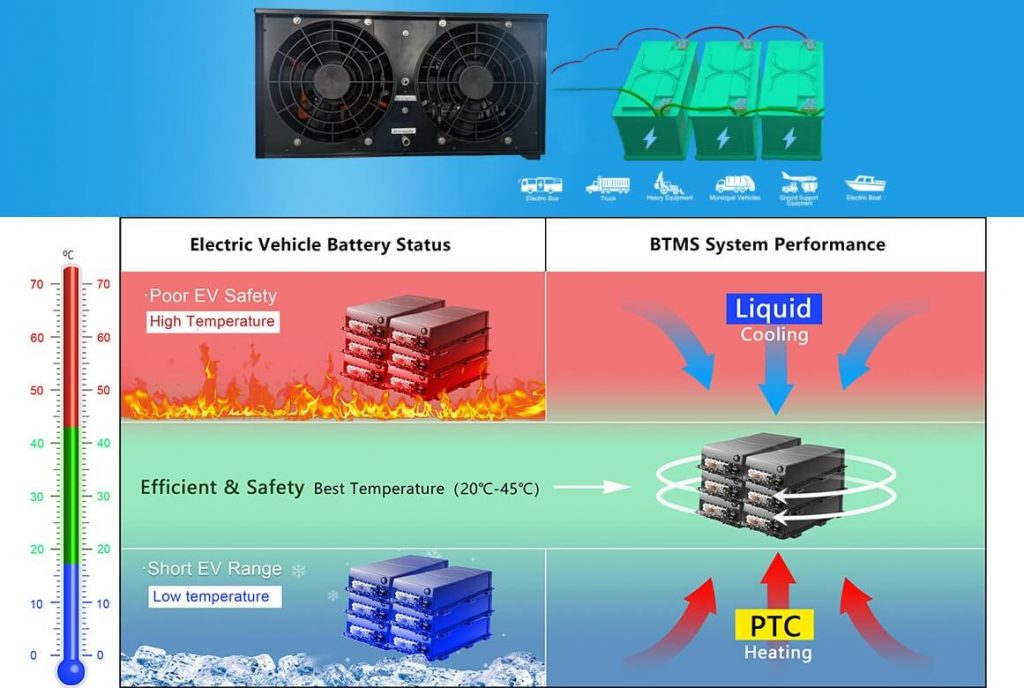

1.3 Risk of thermal runaway of EV battery: High temperature (>60℃) will trigger oxidation of electrolyte, leading to battery bulging. If the temperature continues to rise (>80℃), it may trigger the thermal runaway of EV, directly scrapping the battery or even vehicle combustion.

2.1 Decreased diffusion rate: the viscosity of the electrolyte increases at low temperatures, and the diffusion rate of lithium ions in the electrolyte decreases, leading to a significant increase in the internal resistance of the battery. The internal resistance at low temperature is 2-5 times higher than that at room temperature. When charging and discharging, the polarization voltage increases, and lithium metal is deposited on the surface of the negative electrode to form needle-like crystals. This needle-like crystal is called lithium dendrite. It will pierce the SEI membrane, causing a micro-short circuit and accelerating capacity decay.

2.2 Decrease in electrode activity: the difficulty of lithium ion de-embedding of anode materials increases at low temperatures, resulting in a decrease in the actual usable capacity. For example, the battery capacity at -10℃ is only 50% of the normal temperature. The electrolyte conductivity also decreases under long-term low temperature, further reducing the activity.

Even if the overall temperature of the battery pack is appropriate, too large a temperature difference between the cells can result in a shorter life. For example, if some batteries have a temperature of 35°C and some batteries have a temperature of 25°C.

The core objective of the EV battery thermal management system is to control the battery temperature in the “optimal operating range”, usually 25-40°C. The temperature difference within the cell is reduced (≤5°C), thus suppressing the aging process. It is also necessary to reduce the temperature difference between the battery packs in order to inhibit the aging process described above. TKT is the leading BTMS system specialist.

Battery Liquid Cooling System: The temperature of the battery cell is controlled below 55°C by circulating coolant to remove heat from the battery. For example, the liquid-cooling system in the Tesla Model 3 controls the maximum temperature of the battery cells to 55°C. This is a significant increase in cycle life compared to batteries without thermal management (source Tesla Technical Paper). This results in more than a 30% increase in cycle life compared to batteries without thermal management (source: Tesla Technical White Paper).

PTC Heating: At low winter temperatures, the thermal management system preheats the battery from -20°C to more than 5°C via a PTC heater. For example, BYD Auto can warm up the battery cell to 15°C in -10°C environment, which increases the battery efficiency from 60% to 90% (experiments show that the battery cycle life is 20% longer than that without preheating).

Liquid cooling/liquid heating equal flow design: By optimizing the layout of the cooling pipeline, such as serpentine flow channel and parallel shunt. The new design approach ensures uniform coolant flow for each battery pack cell, controlling the temperature difference within 5 degrees.

Tests by Oak Ridge National Laboratory (ORNL) show that the capacity retention rate of lithium iron phosphate batteries without thermal management system is only 65% after 500 cycles in 45℃ environment; while the capacity retention rate of the same type of battery equipped with battery liquid-cooling system is still 82% after 1,000 cycles.

The battery thermal management system for electric vehicles inhibits phenomena such as accelerated battery aging and thermal runaway of electric vehicles from the root by precisely controlling the temperature range and narrowing the temperature difference within the battery pack. It is coy. This system is a necessary one for electric vehicles. It is an important part of BMS. Electric car battery thermal management systems and electric bus battery thermal management systems are similar in principle, but require higher cooling efficiency and safety.

TKT EV Solution is a leading expert in battery thermal management systems for commercial electric vehicles. We are a BTMS manufacturer in China, integrating design, production and sales. If you have any need in this area, please feel free to leave a message. We support OEM/ODM customization. We have designed integrated system for BYD buses and TATA's electric buses. The new system can cool down the electric bus passengers and battery together at the same time. Highly integrated system is more practical. If you have the need in this area, please feel free to leave a message.

Click on the image to enlarge

Facebook: https://www.facebook.com/TKTHVAC/

Linkedin: https://www.linkedin.com/company/tkt-hvac

Youtube: https://www.youtube.com/@TKTHVAC