1. Customized: Dimension/ Cooling/ Heating etc.

2. World Top 500 TATA Supplier

3. Over 200,000 units in operation worldwide

4. 10 Years of Experience in R&D and Design

5. ISO9001: 2015 Quality Control Certification

6. Application: Bus Battery Chiller&Battery Heater / Truck Battery Chiller&Heater / Heavy Equipment Battery Chiller&Heater ect.

The optimal operating temperature of the battery is 20° to 45°. If this temperature is exceeded, the driving range and the life of the battery will drop dramatically. What’s more, it may also affect the surrounding equipment and cause the consequences of combustion and explosion. That’s why electric vehicles especially need a battery thermal management system, which we also call a BTMS or battery cooler or battery pack cooling system.

If the battery is below this temperature, its electrochemical reaction activity will become poor and the performance of the battery will be greatly reduced. It may even cut off the power directly. Our product can heat it, so we call it battery heating or battery heater.

TKT BTMS is now available for electric buses, electric trucks and electric heavy machinery. There are 8 options for you to choose from. We also offer customization services.

▲More than 10 years of market proof, over 200,000 units in operation worldwide, with quality and performance widely recognized worldwide.

▲Patent Design to make higher cooling/heating with less weight;

▲Bigger Coolant flow to maintain battery temperature in shortest temperature;

▲CAN Control to avoid the wrong operation to damage battery pack;

▲Adopt IP67 electric parts, such as electric compressor, water pump, connectors ect;

▲Fast OEM/Customized Design (1 month);

▲Precise Temperature Control (0.5 Deg.C);

| Product Model | Application | Cooling Capacity |

Customized |

|

8R/8S |

11-12M Electric Bus BTMS |

Cooling 8-10KW

Heating 6-10KW |

Dimension/

Cooling/ Heating |

|

5R/5S |

9-10M Electric Bus BTMS |

Cooling 5-6KW

Heating 3KW |

Dimension/

Cooling/ Heating |

|

3R/3S |

6-7M Electric Bus BTMS |

Cooling 3-4KW

Heating 1-2KW |

Dimension/

Cooling/ Heating |

|

5S–EVT |

Electric Truck BTMS |

Cooling 5-6KW

Heating 3KW |

Dimension/

Cooling/ Heating |

|

3R–EVHE |

Electric Heavy Equipment BTMS |

Cooling 3-4KW

Heating 1-2KW |

Dimension/

Cooling/ Heating |

|

3S–EVHE |

Electric Heavy Equipment BTMS |

Cooling 3-4KW

Heating 1-2KW |

Dimension/

Cooling/ Heating |

Over the past 10 years, TKT has designed and manufactured Battery Pack Cooling System according to the requirements of different OEM customers, such as BYD, Yutong and Golden Dragon in China, and TATA Motors in India, Daewoo in Korea and other overseas markets. The cooling capacity and heating capacity of Battery Thermal Management System(BTMS) ranges from 3-10KW according to customer’s requirements, which can meet the requirements of different commercial vehicles even if the ambient temperature reaches 60 degrees C or -20 degrees C. TKT also makes roof-mounted Battery Chiller, side-mounted Battery Chiller and chassis-mounted Battery Chiller according to the requirements of different customers.

“EV Battery Thermal Management Case Study – A Customized Story for Fortune 500” Click to read (highly recommended)

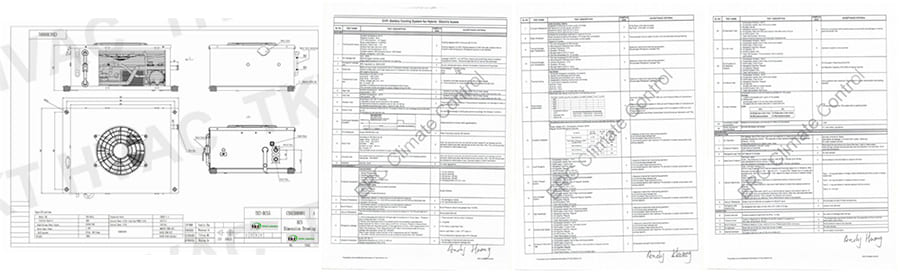

Contact us for High Resolution Images

Condenser coil, condenser fan, water tank, water pump, heat exchanger, electric compressor, control panel, CAN module, expansion valve, etc.

The condenser system cools down the coolant and the water pump will run the coolant through the BCS and the battery structure system to release the heat generated by the battery pack.

TKT HVAC has 25 engineers with master and PhD degrees, 480 workers with 4-8 years of assembly experience, and 85 countries to provide you with perfect after-sales service. With more than 210 patents and CE, EMI/EMC certifications for major products.

TKT is an ISO 9001:2015 certified factory with more than 210 patents for automotive components and systems, and CE, EMI/EMC certifications for major products.

The materials used in all TKT products are internationally recognized brands. Such as Bitzer, Bock, Danfoss, Sanden, Valeo, Alco and Goodyear. We insisting on using copper tubes and aluminum plates will make the products more durable and extend their lifespan.

TKT provides OEM cooperation services for the world’s top 500 companies such as TATA (India). The projects mainly include bus air conditioners, battery cooling systems, etc.

TKT keeps an engineer team with 135 members, such as design engineer, structure engineer, electrical engineer, testing engineer, EMI/EMC engineer, after sales engineer ect., and has the complete ability of bus air conditioner and parts design, development, testing and certification.

TKT has an experienced after-sales team in China and around the world, providing local service in 85 countries and extensive after-sales technical support.

Payment Terms

For small order:

1)100% T/T in advance is acceptable

2)receive payment from Alibaba Trade assurance system

For big value order:

50% T/T deposit, 50% balance before shipping

Warranty Policy

1) 18 Months Free Warranty Time;

2) Free Spare Parts Delivered in Advance;

3) Local Free Service during Warranty Period;

Specific products and accessories may be longer, please leave a message for detailed consultation.

Battery cooling technology is more demanding for the design of electric buses and electric trucks, which TKT has been working on since 2012.

The most effective solution to improve driving range without increasing the number of batteries is a custom battery thermal management system.

EV Battery Thermal Management Case – Customized for Fortune 500. TKT’s BTMS has 10 years of design experience.