With the rapid growth in global electric vehicle sales, EV charger solutions are emerging as the focal point of a new wave of technological competition. According to the latest industry data, the global market size for DC charging stations for passenger vehicles reached US$500 million in 2024 and is projected to exceed US$1.100 billion by 2031, representing a compound annual growth rate of 13%. So, how does one select the appropriate charging station? This is of the utmost importance. A high-quality electric vehicle charger not only impacts charging speed but also directly influences the vehicle's range capability and safety.

AC EV chargers are primarily designed for domestic use and can be understood as slow chargers in comparison. Their principle involves converting mains AC power into DC via an on-board charger before delivering it to the battery. Typically operating at 7-22kW, they are suitable for overnight home charging or extended parking periods at workplaces.

DC EV fast chargers are predominantly commercial in nature, designed for public and commercial premises. Their mechanism involves internal conversion, delivering high-power direct current directly to the vehicle battery. Operating at power levels ranging from tens to hundreds of kilowatts, they can charge smaller vehicles to approximately 80% capacity within a few dozen minutes. Consequently, such charging points are well-suited for deployment at motorway service stations, dedicated EV charging stations, and similar high-traffic locations.

Two DC fast chargers on the left, two AC chargers on the right.

1. Initially, the electric vehicle's BMS system and the charger system undergo connection testing and safety verification to ensure proper communication and interface functionality.

2. The EV charger system and the vehicle's BMS exchange battery status and the maximum acceptable charging power.

3. The EV charger outputs the appropriate voltage/current according to the EV's BMS commands, whilst continuously monitoring data such as voltage, current, and temperature to ensure the charging process remains safe and stable.

1. Charging method and power: There is a significant difference in charging speed between direct current (DC) and alternating current (AC). DC charging is faster, while AC charging is slower.

2. Battery capacity: The larger the battery capacity, the longer it takes to fully charge.

3. Maximum power the vehicle can accept: Even when connected to a higher-power charger, the vehicle's battery management system will limit the actual charging rate.

4. Ambient temperature and battery management strategy: At extreme temperatures, the BMS restricts charging rates to protect the battery. Exceeding temperature limits reduces battery lifespan and risks combustion. Consequently, the BMS limits the actual charging speed.

5. EV charger conversion efficiency: This factor contributes minimally, typically not exceeding 1%.

EV chargers connect to high-voltage electricity at one end, which is potentially lethal. At the other end, they connect to your valuable electric vehicle. Should any issue arise at either end, the consequences could be extremely serious.

1. Safety: Multi-layered protection is paramount. TKT provides, but is not limited to, lightning protection, over-temperature safeguards, overvoltage protection, earth leakage protection, and emergency stop mechanisms.

2. Compatibility: Verify support for your vehicle's specific connectors and communication protocols (e.g., CCS2, CHAdeMO, GBT).

3. Intelligent Features: Dynamic load balancing, remote real-time monitoring, and app-based control enhance user experience and profitability.

4. Reliability and after-sales service: Opt for brands offering warranty coverage with technical support.

What is dynamic load balancing?

Dynamic load balancing automatically adjusts charging power based on the current household electrical load. This feature effectively prevents circuit breakers from tripping and reduces the need for upgrading domestic power capacity (lowering expenditure). It intelligently distributes electricity between the protection system and other electrical appliances, making it a highly practical function for households and small businesses.

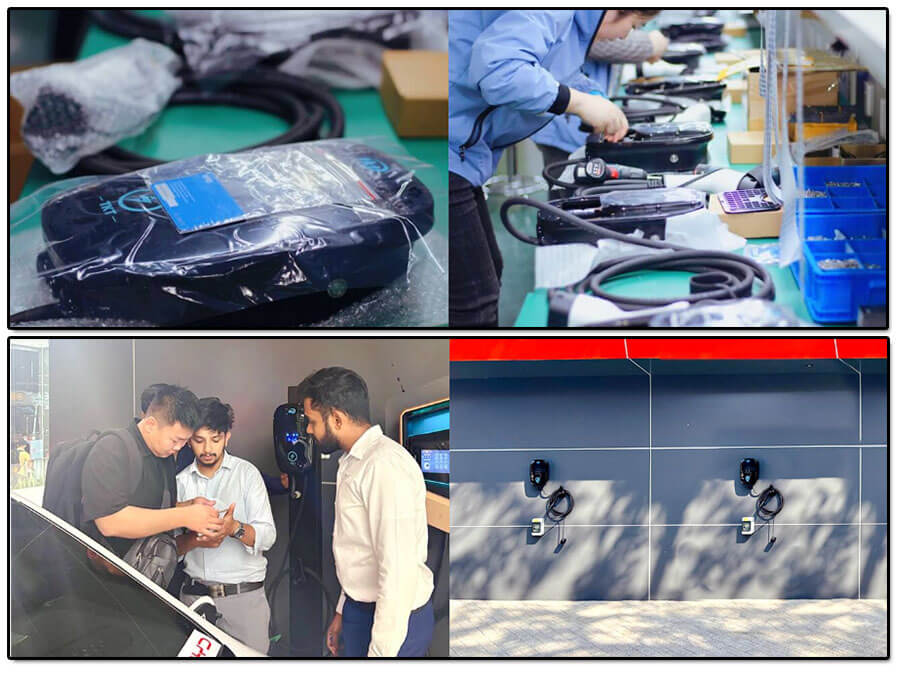

Examine whether the EV charger manufacturer possesses genuine OEM collaboration experience. If so, relevant content is typically featured in their website gallery or news section. Such manufacturers' EV charger solutions have undergone sample testing across diverse climatic conditions and offer robust after-sales support. Only through these criteria can opportunities for major OEM partnerships arise.

For instance, TKT maintains a close partnership with major automotive manufacturer BYD. We serve as their designated charger supplier for the Sri Lankan market. This collaboration demonstrates our strengths across multiple domains, including product manufacturing, OEM design capabilities, and after-sales service. Such partnerships provide valuable reference points for evaluating charger manufacturers' capabilities.

EV charger solutions involve high-voltage electricity and are not merely simple electrical equipment. Safety, compatibility, and intelligent management are equally crucial. For further product details, please click here.

TKT products are sold in 85 countries and regions, trusted by Fortune 500 enterprises such as BYD and Tata. Established in 1998 and headquartered in Henan, China, TKT is a leading manufacturer and supplier in electric vehicle thermal management and charging systems. The company holds ISO 9001 and IATF 16949 certifications, alongside hundreds of component and system patents.

Further reading: 180kw EV Charger: High-Efficiency Charging Powering the Future, What’s the Best EV Car Charger? 7kw EV Charger Details and Major Cooperation with BYD

Facebook: https://www.facebook.com/TKTHVAC/

Linkedin: https://www.linkedin.com/company/tkt-hvac

Youtube: https://www.youtube.com/@TKTHVAC