There are many brands of bus air conditioners in the world. They have high and low prices. What factors affect the bus air conditioner price? In this article, I will start you off with the hardware.

Many components work together to achieve the cooling, heating, and air purification functions of the bus air conditioner system. The main components include compressor, condenser, evaporator, bus air conditioner housing, expansion valve, temperature sensor, evaporator fan, condenser fan, solenoid clutch, fluid reservoir, drier, sight glass, etc.

The most costly components are usually, the compressor, condenser, evaporator, and high quality fiberglass housing.

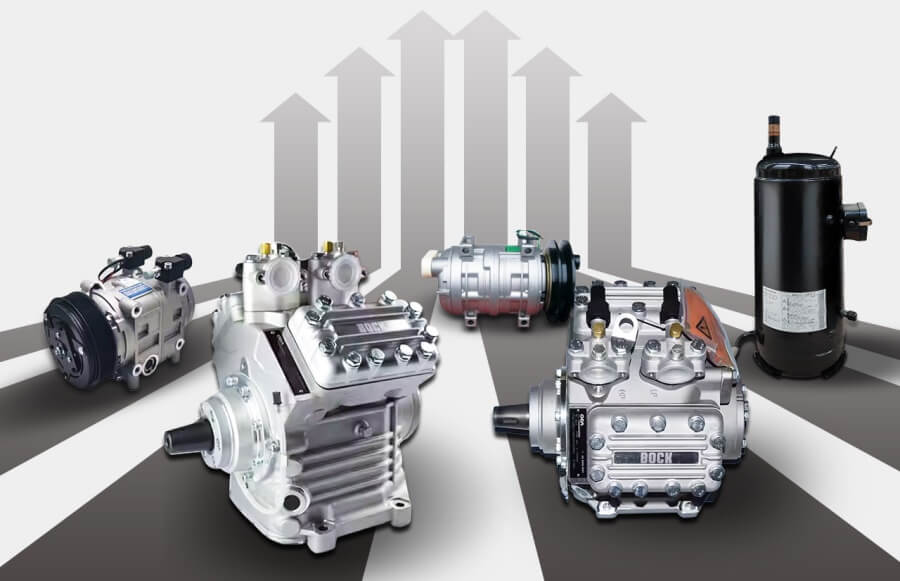

Bus Air Conditioning Compressor: the compressor is the core component of the air conditioning system. It is responsible for compressing and transferring the refrigerant into a high-pressure, high-temperature gas. The performance quality of the compressor directly affects the cooling effect and energy consumption of the bus air conditioner. The bus air conditioner price involves various considerations, and among them, the brand and model of the compressor stands out as one of the important factors. Therefore, the choice of compressor significantly influences the overall cost of the bus air conditioning system. I will explain the compressor to you in a simple and easy-to-understand way.

First of all, Bus air conditioning compressor recommended selection of Bock, SANYO, Valeo and other world brands, more reliable quality, longer service life.

Secondly, besides the brand, the choice of model is very important. We have strict criteria for choosing models. The length of the bus is different, and the cooling capacity needed is different, so the matching compressor model is also different.TKT is serious about bus air conditioning solutions, and will not choose a low-matched solution to reduce costs. Therefore, our bus air conditioners can meet the requirements of the T3 environment. TKT Bus HVAC has existed for 24 years. We are in a long-term business and aim to be a hundred years enterprise.

Finally, please be sure to recognize the scroll compressor. The scroll compressor is the latest type of compressor after the reciprocating compressor, rotor compressor, and screw compressor. Recognized as a technologically advanced third-generation compressor, it is a high-efficiency volumetric compressor. It has a number of significant advantages:

Compact Structure: volume reduced by about 40%.

Low Noise: noise reduction of 5-8 dB.

High Efficiency: efficiency increased by 10%.

Light Weight: weight reduction of 15%.

These advantages make the scroll compressor have smooth running, low vibration, a quiet working environment, and other characteristics. It is also of higher quality and has been described as a “maintenance-free compressor”. It is widely used in high-grade buses. High quality bus air conditioners use good compressors, then the bus air conditioner price will increase.

The condenser is responsible for cooling the high-temperature, high-pressure refrigerant into a high-pressure liquid while releasing heat into the outside air. The evaporator is another important component in the air conditioning system, which utilizes the process of evaporation of the refrigerant at low pressure to absorb heat and thus achieve the cooling effect.

The material, structure, and heat dissipation performance of the condenser and evaporator will affect their price, which in turn will affect the overall the bus air conditioner price.

There are two main types of evaporator and condenser cores, the parallel flow type and the copper tube and aluminum sheet type. Most of the bus air conditioner manufacturers usually opt for parallel flow. TKT uses copper tube aluminum sheet type for the sake of the quality of bus air conditioners.

A. Thermal Conductivity: The Copper Tube Aluminum Chip Type core combines the high thermal conductivity of copper tubes with the good heat dissipation properties of aluminum sheets. This combination makes the copper tube and aluminum sheet-type core excellent in heat transfer.

B. Corrosion Resistance: Copper has good corrosion resistance and is able to maintain its performance in a variety of environments. Especially for coastal cities. The humidity in the air is higher. If the choice of parallel flow core. It is very easy to cause destruction.

In addition to the superiority of the core type, we also hold the core patented technology. Our craftsmanship in making the core is much more advanced. We can do 21mm (industry average is 25mm). In the same area, our copper tube gap is smaller and more copper tubes. This can improve the heat exchange efficiency of the core. A better core can affect the bus air conditioner price.

The bus air conditioner shell is usually made of two materials. One is PC/ABS material and the other is fiberglass. PC/ABS is a plastic alloy, made from a blend of two plastics, PC and ABS. Whereas fiberglass(FRP) is a fiber reinforced plastic, consisting of glass fibers and a resin matrix.

A. High strength and hardness: by combining glass fiber with resin, FRP forms a strong structural property that can withstand large external pressure and impact.

B. Corrosion resistance: FRP enclosure is not affected by the external environment such as air, rain, chemicals, etc. It can effectively avoid rust, corrosion, and oxidation.

C. High and low-temperature resistance: FRP shell has good ability of high and low-temperature resistance, and will not deform or lose strength because of temperature change.

D. Aging resistance: FRP has high chemical and physical stability and can withstand long-time wind and sunshine.

Fiberglass reinforced plastic (FRP) shell is more difficult to process and more expensive to produce due to its high durability. However, TKT attaches more importance to the quality of bus air-conditioners, so the FRP material is chosen. Such a choice will increase the bus air conditioner price to some extent.

Although the bus air conditioner price has gone up a little bit, it's all because the highest quality parts are used. You get what you pay for. High-quality parts have a very important impact on the life and stability of your bus air conditioner. I'm sure no one would want to end up with it malfunctioning in the summer when they need it the most.

TKT was founded in 1998 and is headquartered in Henan, China. We are a leading manufacturer and supplier in the field of thermal control systems and charging systems for electric vehicles. Its main products include Battery Thermal Management System (BTMS), Electric Vehicle Bus Air Conditioner, Electric Vehicle Charger, etc.

TKT is ISO 9001:2015 and IATF 16949:2016 certified, and holds hundreds of patents for automotive components and systems. TKT also holds hundreds of patents for automotive components and systems. The main products have obtained CE, EMI/EMC certificates.

Facebook: https://www.facebook.com/TKTHVAC/

linkedin: https://www.linkedin.com/company/tkt-hvac

YouTube: https://www.youtube.com/@TKTHVAC