TKT is a leading global expert in battery thermal management solutions. Designed for electric buses, electric trucks, electric heavy equipment, and electric boats. We have provided reliable battery liquid cooling systems to many well-known global automakers, including BYD and Tata Motors, helping to extend the lifespan, safety, and range of electric commercial vehicles.

We leverage 25 years of experience in vehicle thermal management and industry-leading design and manufacturing capabilities to enhance the performance of your commercial vehicles. Our battery thermal management products are renowned for their powerful cooling performance of up to 10 kW, precise temperature control to within 0.5 degrees, plug-and-play design, and OEM/ODM customization.

Specially designed for electric bus BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 8KW / 5KW / 3KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

Specially designed for electric truck BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 5KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

Specially designed for heavy equipment BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 8KW / 5KW / 3KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

Specially designed for electric marine BTMS, battery liquid cooling.

1. Cooling Capacity: 10KW / 8KW / 5KW

2. Voltage Range: DC 220V-750V

3. Customized: Heating / OEM / Dimension

4. Advantages: 0.5 ℃ precise temperature control. Plug and play. Fortune 500 supplier.

Battery thermal management (BTM) involves actively or passively regulating the temperature of a battery pack to maintain it within the ideal operating range of 10°C–45°C. More advanced technical requirements also include controlling the temperature difference between each battery in the battery pack to below 5°C. Its core functions include cooling, heating, and temperature balancing, ensuring safe and efficient operation of the battery pack under various environmental conditions.

Its core objectives are:

1. Prevent thermal runaway: Avoid high temperatures triggering chain exothermic reactions (such as fires or explosions);

2. Optimise battery performance: Heat the battery pack at low temperatures to enhance discharge capacity and cool it at high temperatures to maintain power output;

3. Extend battery lifespan: Reduce temperature fluctuations that cause battery degradation (such as lithium plating or thickening of the SEI film).

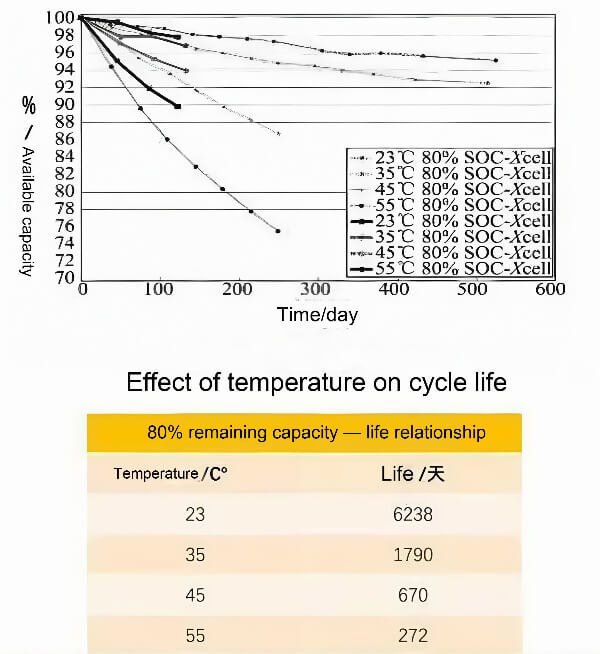

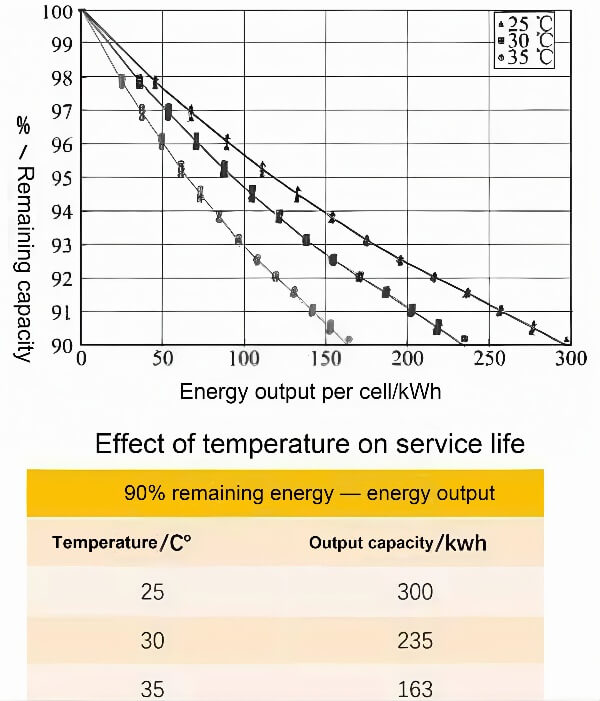

Power batteries are the energy source for electric vehicles. During charging and discharging, the batteries themselves generate a significant amount of heat, leading to an increase in temperature. Elevated temperatures can affect various battery characteristics, such as internal resistance, voltage, state of charge (SOC), available capacity, charging/discharging efficiency, and battery lifespan.

Battery thermal effects also impact vehicle safety, performance, and battery cycle life. I will elaborate on these points in the following sections, so please continue reading. Therefore, battery thermal management is of utmost importance.

Currently, the most reliable and practical solution for EV battery thermal management is liquid cooling technology. I will use liquid cooling as an example to explain.

1. Heat absorption (battery → coolant)

The heat generated during battery charging and discharging is transferred to the liquid cooling plate in contact with the battery via thermal conduction. The coolant flows through the microchannels inside the liquid cooling plate, absorbing heat through convective heat exchange, causing the coolant temperature to rise.

2. Heat transfer (coolant → radiator)

The heated coolant is driven by an electric water pump and transported through pipes to the radiator. The radiator dissipates the heat into the environment through forced air cooling, causing the coolant temperature to decrease.

3. Circulation

The cooled coolant returns to the liquid cooling plate, forming a closed-loop circulation.

In summary, its operating principle is based on the physical mechanisms of heat conduction and convective heat transfer, achieving the absorption, transfer, and dissipation of battery heat through a closed-loop coolant system.

Generally, there are two main types: active cooling and passive cooling. The main difference is whether energy consumption occurs. If energy consumption occurs, it is active cooling; if there is zero energy consumption, it is passive cooling.

The active cooling system includes the following:

1. Air-cooled cooling system

This system primarily utilises the principle of air convection to circulate air within the battery compartment. The circulating air carries away heat from the batteries, thereby lowering their temperature. Simultaneously, the air undergoes further heat exchange within the evaporator, where the refrigerant evaporates to reduce the temperature of the circulating air.Advantages: Simple system structure, low cost, and easy maintenance.

Disadvantages: Poor high-temperature heat dissipation performance, low low-temperature startup efficiency, and uneven stability between batteries.

2. Refrigerant direct cooling system

This system primarily utilises the latent heat of evaporation principle of refrigerants. An air conditioning system is established within the battery system, with cooling plates installed within the battery system. Refrigerant evaporates within the cooling plates, rapidly and efficiently removing heat from the battery system to achieve cooling.

Advantages: Simple structure, theoretically uniform temperature distribution, and good cooling performance;

Disadvantages: Currently, the technology is not yet mature, and commercialisation is unlikely in the short term.

3. Integration: Shared Water-Cooled Cooling System

A plate heat exchanger is added and coupled to the air conditioning system. The batteries exchange heat with the coolant through the cooling plates. The cooled or heated coolant is pumped into the plate heat exchanger, where refrigerant flows into one side and coolant flows into the other. Heat is removed by the refrigerant, and the coolant flows out of the plate heat exchanger and back into the batteries, completing the cycle.

Advantages: Compact structure, integrated battery heating components, high low-temperature start-up efficiency, excellent high-temperature cooling, and uniform temperature distribution.

Disadvantages: Multiple system components and complex control strategy.

4 Independent Battery Liquid Cooling System

When the battery needs cooling, it exchanges heat with the coolant through the cooling plate. The heated coolant is pumped into the plate heat exchanger by an electronic water pump. Inside the plate heat exchanger, refrigerant flows into one side and coolant flows into the other, where heat is exchanged. The heat is removed by the refrigerant, and the coolant flows out of the plate heat exchanger and back into the battery, completing the cycle.

When the battery needs heating, the cooling circuit is closed and the PTC liquid heater is activated. The heated coolant is then fed into the battery, where it heats the battery through the cooling plate. The internal battery temperature is controlled by controlling the cooling circuit and the PTC liquid heater.

Advantages: Compact structure, integrated battery heating components, high low-temperature starting efficiency, excellent high-temperature cooling, and uniform temperature distribution.

Disadvantages: Multiple system components and complex control strategy.

The independent battery liquid cooling system consists of a compressor, condenser, expansion valve, plate heat exchanger, electronic water pump, PTC liquid heater, expansion tank, and electrical control.

Passive cooling systems include the following:

1. Phase Change Material Battery Thermal Management (PCM-BTM)

This system utilizes the latent heat properties of phase change materials (PCMs), absorbing or releasing heat through solid-liquid phase transitions. It transfers heat through the physical properties of the material, eliminating the energy consumption of active cooling systems.

Advantages: No energy consumption, consistent temperature.

Disadvantages: Heavy weight, short lifespan.

2. Heat Pipe Technology

Heat pipe technology is a highly efficient thermal conductivity element that utilizes phase change in liquids for heat transfer. It consists of a tube shell, a wick, and end caps. A negative pressure is created inside the tube and filled with a low-boiling-point liquid. When one end is heated, the liquid evaporates and vaporizes. The vapor flows to the cold end, condensing and releasing heat. The condensed liquid then flows back to the evaporating end through capillary action, forming a cycle.

Advantages: No energy consumption, uniform temperature.

Disadvantages: High cost and complex design. It is primarily used in spacecraft equipment.

| Coolant Type | Thermal Conductivity (W/m·K) | Specific Heat Capacity (kJ/kg·K) | Advantages | Disadvantages |

| Ethylene glycol aqueous solution | 0.4 | 3.5 | Antifreeze, low cost | High viscosity, pumping power, oxidation, acid generation, metal corrosion |

| Fluorinated Fluid | 0.07–0.08 | 1.1 | Non-flammable, good insulation, non-corrosive | High cost, high GWP |

| Deionized water | 0.6 | 4.18 | Optimal thermal conductivity, environmentally friendly | High electrical conductivity can cause short circuits |

| Mineral oil | 0.1–0.15 | 1.8 | Good insulation, moderate cost | Susceptible to oxidation and decomposition, high viscosity, poor fluidity |

| Nanofluids | 0.5–0.8 | 2.2 | 40% higher thermal conductivity, suitable for high power density | Extremely high cost, risk of particle settling |