Sistema de gerenciamento térmico de bateria

Ar condicionado elétrico

Ar condicionado acionado por motor

Carregadores EV

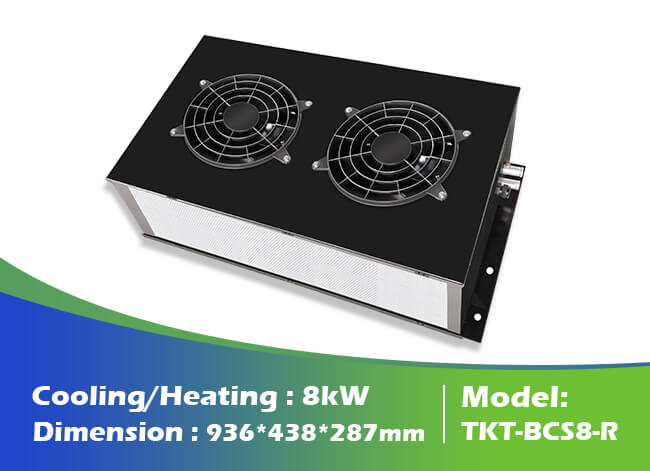

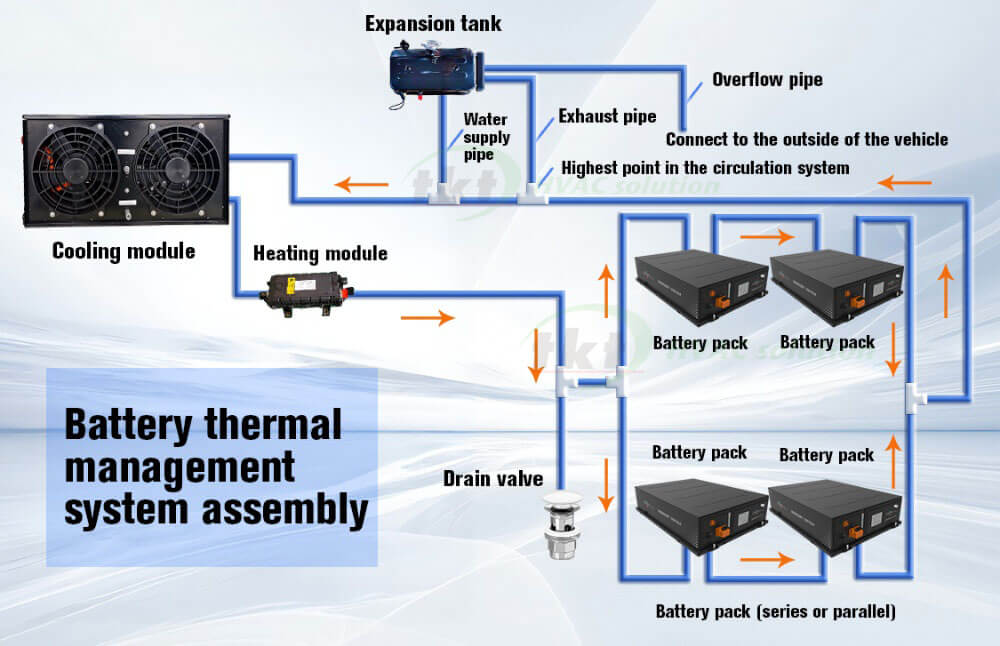

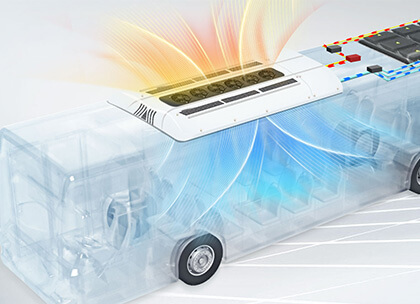

Ônibus elétrico BTMS

Caminhão Elétrico BTMS

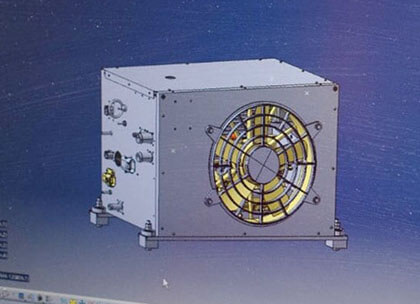

Equipamento E-Pesado BTMS

BTMS personalizado

Soluções BTM

Ar condicionado para ônibus elétrico

Ar condicionado para caminhão

Ar condicionado para trailers

Ar condicionado para veículos comerciais

Solução do clima de ônibus