Battery pack thermal management systems are key to ensuring the safety and efficiency of electric vehicle batteries. This article explores various battery thermal management methods and their importance in electric vehicles and other applications. Understanding these systems is crucial for engineers and battery enthusiasts. It can help design safer and more efficient battery packs and electric vehicles.

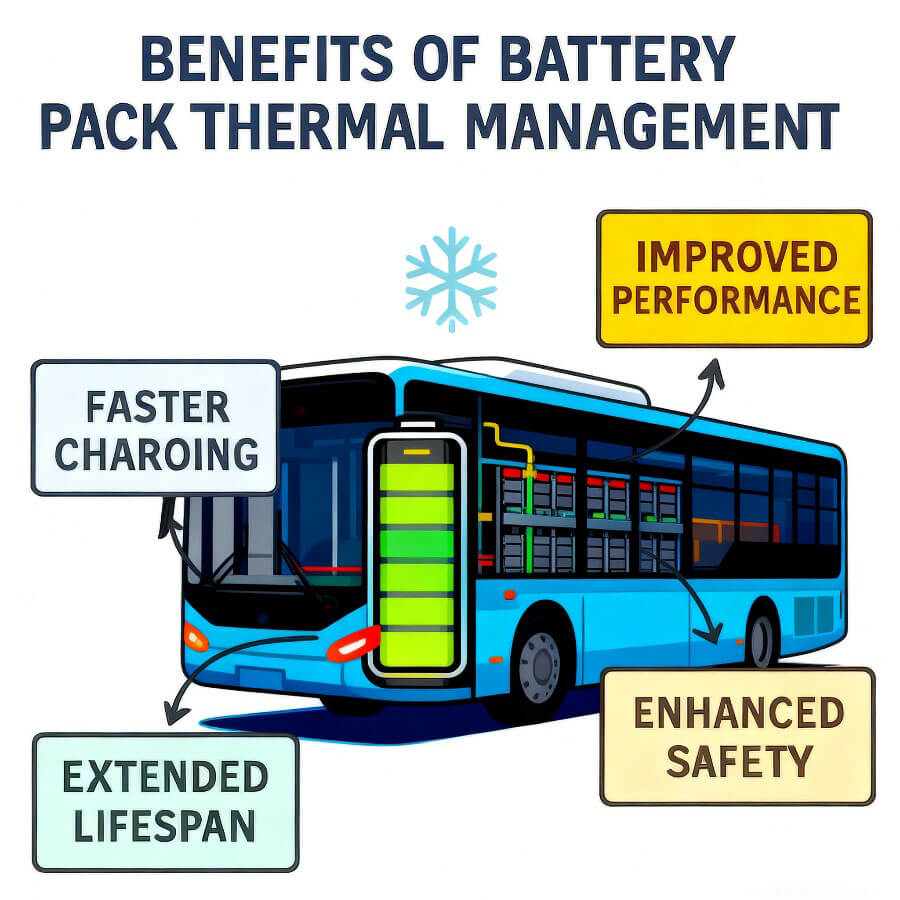

Battery pack thermal management system is crucial to the safety and performance of electric vehicle batteries. The reasons are as follows:

1. It ensures that the battery remains within a safe temperature range. Without a thermal management system, overheating becomes a serious risk. Overheating can rapidly degrade battery performance and shorten battery life. 重症の場合, it can even cause combustion and explosion. This is an irreversible damage process. したがって, controlling the temperature can effectively prevent these consequences.

2. Maintaining a suitable temperature range also improves battery efficiency, which is crucial for applications such as electric vehicles. Higher energy efficiency means longer driving range. Reduced charging times lead to higher profits and a better driving experience.

全体, battery pack thermal management is essential for vehicle electrification. It contributes to safe and efficient energy solutions and aligns with sustainable development goals. Understanding these systems is crucial for engineers and designers. 現在, liquid battery cooling is the mainstream thermal management approach.

Maintaining your battery pack within its optimal temperature range is crucial. Most lithium-ion batteries perform best between 20°C and 45°C. At higher temperatures, reactions within the battery accelerate, potentially causing irreversible damage. 逆に, lower temperatures slow chemical reactions, resulting in a shorter battery life.

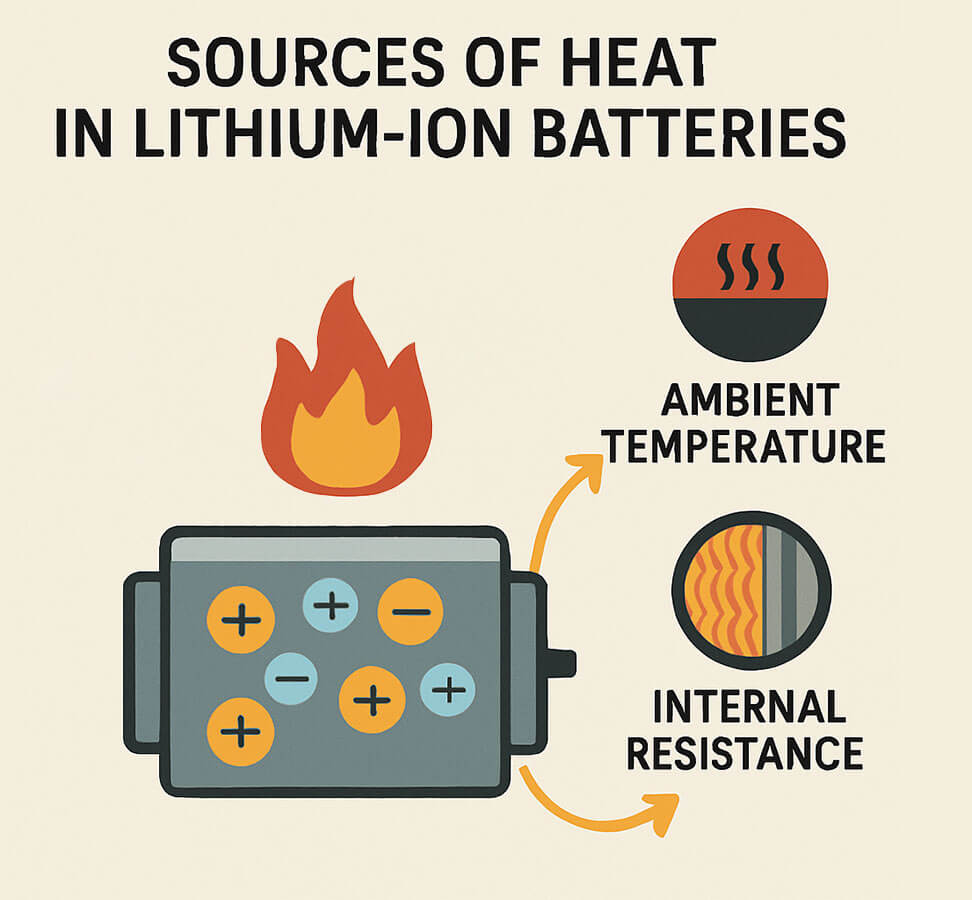

1. Lithium-ion battery packs generate heat from a variety of factors. A primary source is heat generated by internal resistance during the charge and discharge cycles, especially at high power outputs.

2. The external environment also affects heat generation. High temperatures can exacerbate internal heating.

Due to different cooling methods, the specific components vary. しかし, the key components all include a cooling circuit, a control unit, and sensors.

1. The cooling circuit ensures the system effectively dissipates heat from the battery cells.

2. The control unit adjusts the frequency and efficiency of the cooling equipment based on real-time data.

3. Sensors monitor critical information such as battery temperature. They provide real-time information to the system, enabling precise adjustments. These components work together to achieve the goal of battery thermal management.

Passive and active thermal management methods have significant differences in their impact on battery temperature. Passive systems typically leverage natural processes without mechanical or electrical intervention. These methods often employ materials that naturally dissipate heat.

対照的に, active systems utilize external energy sources to control temperature. These systems typically include fans, pumps, or coolants. In high-performance environments, active methods offer more precise temperature regulation and better thermal management.

Each method has its uses and advantages depending on its characteristics. Passive methods are generally simpler and less expensive, but are limited to devices with smaller battery capacities. Active systems, 一方で, are essential for typical commercial vehicles and energy storage devices. They offer better temperature control but come with increased complexity and cost.

Air cooling and liquid cooling are common methods for managing battery temperature.

Air cooling is simple and cost-effective. It uses fans to circulate air to remove heat from the battery surface. しかし, airflow speed is limited, and air heat exchange efficiency is low. したがって, air cooling may not be sufficient for high-power applications.

Battery liquid cooling uses a coolant to circulate around the battery cells, absorbing significant heat and preventing temperature spikes. This method is particularly effective for electric vehicles. It helps maintain a stable thermal state, thereby extending battery life, 安全性, and range. Compared to air cooling, its design is more complex and requires careful design to prevent coolant leaks. Although liquid battery cooling systems increase weight, their advantages are more significant.

Advantages of Battery Liquid Cooling:

1. Efficient thermal management: Ensures uniform temperature across battery cells.

2. 安全性の強化: Reduces the risk of thermal runaway by controlling thermal peaks.

3. Extends battery life: Maintains an ideal thermal state, thereby extending battery life.

Innovation in battery cooling is rapidly evolving. New technologies must provide efficient thermal management without adding additional weight or cost. Foreseeable new technologies include:

1. ナノ流体: These utilize nanoparticles to enhance cooling performance.

2. Phase change materials: These utilize the absorption and release of heat during material transitions to regulate temperature.

3. バッテリー浸漬冷却: This involves fully immersing the entire battery pack in a non-conductive, non-flammable dielectric coolant for efficient heat exchange.

Battery pack thermal management is critical to the reliability and performance of next-generation batteries, ensuring safe and efficient operation. 現在, its primary applications are in electric vehicles and energy storage. We anticipate that this will be needed in a growing number of sectors in the future. As we move toward clean energy, thermal management is essential.

TKT focuses on BTMS design and manufacturing for electric commercial vehicles

TKTは、バッテリーサーマルマネジメントソリューションの世界的な専門家です, specifically designed for electric buses, 電気トラック, 電動重機, and electric ships. Leveraging 25 years of vehicle thermal management experience and industry-leading design and manufacturing capabilities, we can help enhance the performance of your commercial vehicles. We have provided reliable battery liquid cooling systems to numerous global automakers, BYDおよびTATAモーターを含む, extending the lifespan, 安全性, 電気商用車の範囲.

さらに読む: バッテリー浸漬冷却とは, 電気自動車とバッテリー寿命用のバッテリーサーマル管理システム, 電気バス用のバッテリー冷却システムの分析, トラック.

フェイスブック: https://www.facebook.com/TKTHVAC/

リンクトイン: https://www.linkedin.com/company/tkt-hvac

ユーチューブ: https://www.youtube.com/@TKTHVAC