Dirancang khusus untuk alat berat BTMS, pendingin cairan baterai.

1. Kapasitas Pendinginan: 10KW / 8KW / 5KW / 3KW

2. Rentang Tegangan: DC 220V-750V

3. Disesuaikan: Pemanas / OEM / Dimensi

4. Keuntungan: 0.5 ℃ kontrol suhu yang tepat. Pasang dan mainkan. Harta benda 500 pemasok.

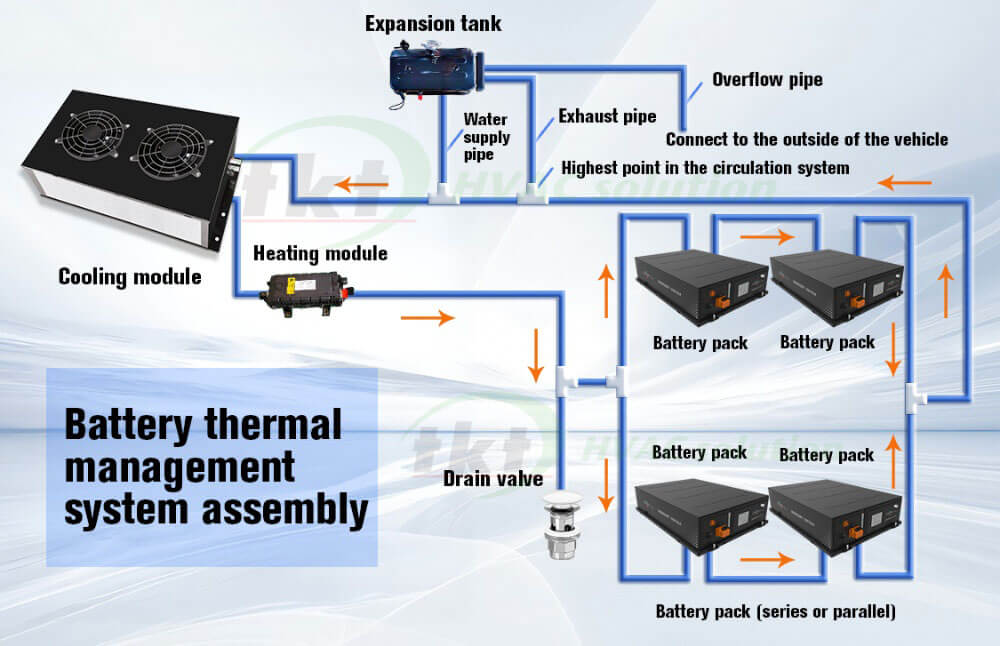

Heavy equipment typically refers to construction machinery and mining equipment, which operate in harsh environments such as high temperatures, high vibration, and high dust levels. The electric heavy equipment BTMS (Sistem Manajemen Termal Baterai) is a specialized temperature control system that cools and heats the power batteries in these devices. Batteries operating within the appropriate temperature range can achieve their maximum performance, extend their lifespan, and prevent thermal runaway in heavy equipment, making it safer.

Batteries in electric heavy equipment typically have capacities ranging from 300 ke 600 kwh, or even 700 kwh. These batteries experience higher instantaneous charge and discharge currents, generating more heat and placing more stringent heat dissipation requirements. Karena itu, the heavy equipment BTMS requires a robust heat dissipation design to withstand extreme temperatures. To meet these demands, the battery cooling system must utilize liquid cooling, which is currently the most mature and economical battery cooling method.

1. High Temperature: Battery temperatures can soar above 85°C (MISALNYA., in desert mining areas) during continuous exposure to sunlight or high-load operation.

2. High Vibration and Shock: When operating or traveling on rough terrain, construction machinery experiences vibrations up to 20-50Hz, making traditional liquid cooling pipes susceptible to loosening or leakage.

3. High Dust and Corrosive Environments: Mine dust can easily clog heat dissipation channels, and salt spray corrosion (MISALNYA., in coastal operations) can corrode metal components, degrading insulation performance.

4. Instantaneous High-Power Charging and Discharging: When electric mining trucks climb slopes or start under heavy load, instantaneous currents can reach hundreds of amperes, generating tens of kilowatts of heat from the batteries. Traditional battery air cooling systems struggle to meet these requirements.

| Model | 10Cw | 8R | 5Cw | 3R |

| Kapasitas Pendinginan | 10KW | 8KW | 5KW | 3KW |

| Dimensi Standar | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 587*355*242mm |

| Berat Standar | 40kg | 40kg | 30kg | 25kg |

| Arah Saluran Keluar Udara | Samping | Atas | Samping | Atas |

Hubungi kami untuk mendapatkan BTMS PDF

TKT didirikan pada 1998. We possess extensive battery thermal management system design experience and manufacturing capabilities. Di dalam 2018, we partnered with TATA Motors, sebuah keberuntungan 500 perusahaan, to develop a custom BTMS. Setelah menjalani beberapa putaran pengujian yang ketat, our product received recognition and praise. Tak lama kemudian, we entered into a second collaboration with them on a BTMS for electric trucks.

BTMS and BMS for electric heavy equipment are the two core subsystems of the battery system. They achieve comprehensive battery management through data sharing and collaborative control.

1. Data Sharing: The BMS transmits battery parameters such as SOC, SOH, and charge and discharge currents to the BTMS in real time. The BTMS dynamically adjusts cooling and heating power based on this data.

2. Collaborative Control: When the BMS detects an overheating alarm, it immediately initiates forced cooling. If it predicts a low temperature, it initiates preheating. Sebaliknya, if the BTMS detects a cooling system failure, it automatically limits charge and discharge power to prevent battery overheating. They work together to ensure equipment safety and avoid the terrible phenomenon of thermal runaway.

1. “Sistem manajemen termal baterai untuk kendaraan listrik dan masa pakai baterai” Klik di sini untuk melihat

2. “Analisis sistem pendingin baterai untuk bus listrik, Truk” Klik di sini untuk melihat

3. “Sistem Pendingin Cairan Baterai - Bagaimana cara kerjanya?” Klik di sini untuk melihat

4. “Proyek BYD K9: Sistem Pendingin Baterai EV Dikombinasikan dengan Bus A/C” Klik di sini untuk melihat

5. “Baterai BTMS: Prinsip, Desain, Instalasi – TKT HVAC” Klik di sini untuk melihat

6. “Sistem Manajemen Termal Baterai untuk Truk / Bis dll. – Disediakan ke Atas 500 TATA” Klik di sini untuk melihat

7. “Sistem Manajemen Termal Baterai untuk Mobilitas Switch – TKT” Klik di sini untuk melihat

8. “Sistem Manajemen Termal Baterai Khusus (BTMS) – TKT HVAC” Klik di sini untuk melihat

9. “Cara Mendesain Lokasi Pemasangan Bus BTMS” Klik di sini untuk melihat

10. “Pendinginan Baterai | Sistem Manajemen Termal Baterai – TKT” Klik di sini untuk melihat

Klik untuk menelusuri Solusi BTMS untuk bus listrik

Klik untuk menelusuri Solusi BTMS untuk truk listrik

Klik untuk menelusuri Solusi BTMS untuk alat berat listrik

Klik untuk menelusuri Solusi BTMS untuk kelautan listrik

Klik untuk menelusuri Solusi BTMS yang disesuaikan dengan OEM

Artikel ini akan menggunakan beberapa kasus gagal untuk menggambarkan risiko investasi stasiun pengisian kendaraan listrik. Jangan lewatkan jika Anda tertarik!

Pahami Pengisi Daya EV 60kW: Pilihan Pilihan Anda untuk Solusi Pengisian Daya EV yang Cepat dan Efisien. TKT adalah produsen profesional.

Becak listrik roda tiga telah menjadi pilihan terbaik untuk perjalanan jarak pendek di kota dan pedesaan.