Criando uma solução eficiente e confiável para carregamento de ônibus elétricos

Estações de carregamento de ônibus elétricos TKT foram desenvolvidas, projetado, e fabricado desde 2014. Temos ampla experiência em OEM. Nosso inteligente, os sistemas de carregamento rápido são projetados para atender às necessidades das frotas de transporte público, incluindo o fornecimento de personalização OEM. Atualmente, nós somos trabalhando com alguns dos topo do mundo 500 clientes como motores BYD e TATA.

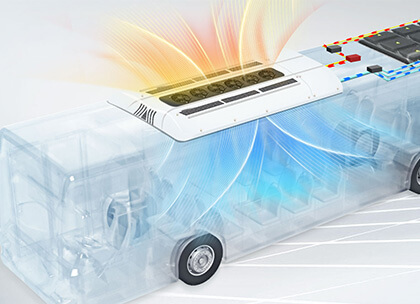

Ônibus elétricos, como meio de transporte público, geralmente são obrigados a operar 24 horas por dia. Alta capacidade de passageiros, partidas e paradas frequentes, e o consumo de energia de equipamentos auxiliares, como aparelhos de ar condicionado, resultam em um consumo de energia muito maior do que os veículos elétricos comuns. Portanto, eles geralmente são equipados com uma bateria de maior capacidade, o que reduz o número de tempos de recarga. Eles também são geralmente equipados com velocidades de carregamento mais rápidas para garantir operação contínua.

Por todas essas razões, projetamos esta solução de carregamento de ônibus elétrico: 120~240kW. Possui duas portas de carregamento e pode carregar dois ônibus elétricos ao mesmo tempo, o que pode aumentar a taxa de utilização. Em segundo lugar, tem uma velocidade de carregamento muito rápida, o que pode reduzir significativamente o tempo de carregamento de ônibus elétricos.

120-240 estação de carregamento rápido KW DC (Clique para detalhes)

O carregamento de uma hora adiciona cerca de 240-480 quilômetros:

Os ônibus elétricos geralmente consomem entre 56 e 60 kWh de eletricidade por 100 quilômetros. Se um carregador de 120 kW for usado para carregar um ônibus elétrico, teoricamente, 120 kWh de eletricidade pode ser cobrado por hora. A autonomia do ônibus elétrico é então aproximadamente 240 quilômetros. Deve-se notar que a eficiência e o alcance reais do carregamento podem ser afetados por uma série de fatores, como a eficiência do carregador, temperatura ambiente, carga do veículo, etc.. Os cálculos acima são apenas para referência.

Se uma estação de carregamento de ônibus elétrico de 120 kW carrega dois ônibus elétricos ao mesmo tempo, a potência de carregamento de cada veículo será de 60 kW.

Contate-nos Obtenha PDF

Que pontos problemáticos o carregamento de ônibus elétrico TKT resolve?

1. Atende à necessidade de reabastecimento de alta frequência/tempo de carregamento reduzido (Alto poder de carregamento)

1.1 Materiais semicondutores de potência avançados: Os carregadores TKT usam materiais semicondutores de potência avançados, como carboneto de silício (SiC) para melhorar a eficiência de conversão e reduzir a perda de energia.

1.2 Design modular: 30O módulo de carregamento de alta potência kW / 40kW é adotado como base. O design modular permite que o carregador expanda de forma flexível a potência de carregamento de acordo com suas necessidades.

2. Satisfazer as necessidades de carregamento dos autocarros multimarcas (Alta compatibilidade)

2.1 Design de interface multipadrão: suporte CCS2, GBT, e outras interfaces de carregamento, compatível com BYD, Yutong, Motores TATA e outras marcas de ônibus.

2.2 Reconhecimento automático de adaptação de protocolo: Várias pilhas de protocolos de comunicação integradas reconhecem automaticamente os protocolos de carregamento do carregamento de ônibus elétrico conectado. Isto melhora a compatibilidade com uma ampla gama de ônibus elétricos e garante uma experiência de carregamento segura e rápida.

2.3 Mais flexível que o carregador pantográfico: não escolher o modelo dos ônibus elétricos, é mais flexível para ser usado como e quando for necessário.

3. Minimize problemas pós-venda (Robusto e confiável)

3.1 Múltiplos mecanismos de proteção, incluindo proteção contra sobrecarga, proteção contra curto-circuito, proteção contra vazamento, Proteção de excesso de temperatura, etc., garantir a operação segura do equipamento em diversas condições de trabalho.

3.2 Componentes de alta qualidade: componentes selecionados de marcas internacionais famosas para garantir estabilidade e durabilidade do produto.

3.3 Função de autodiagnóstico de falhas: monitoramento em tempo real do estado do equipamento, detecção automática e registro de informações de falha, para facilitar ao pessoal de manutenção a localização rápida do problema.

4. Melhorando a eficiência operacional (Sistema de Gerenciamento Inteligente)

4.1 Interface de interação humano-computador: Equipado com tela sensível ao toque de alta definição, suportando comutação multilíngue, operação intuitiva, e melhorando a experiência do usuário.

4.2 Gerenciamento de plataforma em nuvem: Forneça uma plataforma de gerenciamento baseada em nuvem, suporte para monitoramento remoto, análise de dados, diagnóstico de falhas, e outras funções para melhorar a eficiência operacional.

5. Apoiar & Pós -vendas

A TKT possui uma equipe de serviço dedicada para fornecer suporte on -line para nossos sistemas de hardware e software. Você não precisa entrar em pânico se surgirem problemas.

Como os fabricantes originais de carregador de veículos elétricos, O TKT também fornece treinamento sobre manutenção e solução de problemas adequados. Isso ajudará a prolongar a vida útil da estação de carregamento de ônibus elétricos.

-

-

Apoiar & Treinamento

-

-

Serviços ao cliente

-

-

24 Garantia de meses

Projeto de solução de carregamento de ônibus elétrico

Projeto de solução de carregamento de ônibus elétrico

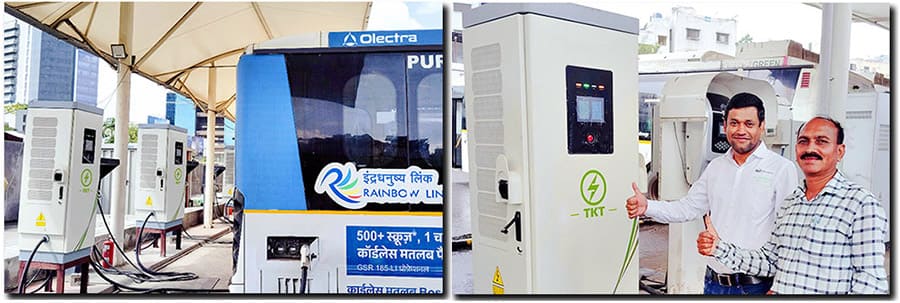

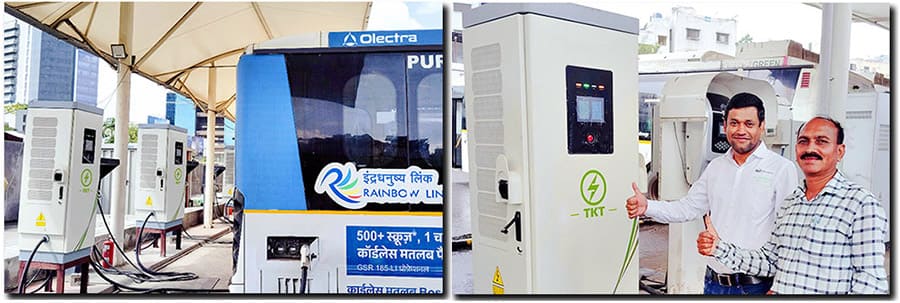

O projeto é a nossa parceria com a Byd-Olectra, Fabricante de ônibus elétricos líder da Índia. O número de carregadores de veículos elétricos rápidos já excederam centenas no primeiro lote.

Como engenheiro elétrico -chefe, Senhor. Dinesh liderou a construção e manutenção da infraestrutura de carregamento. Ele disse, “Seus carregadores de veículos elétricos desempenharam um papel fundamental em nosso projeto. Aumentou muito a frequência das viagens de ônibus.”

Sobre OEM/ODM

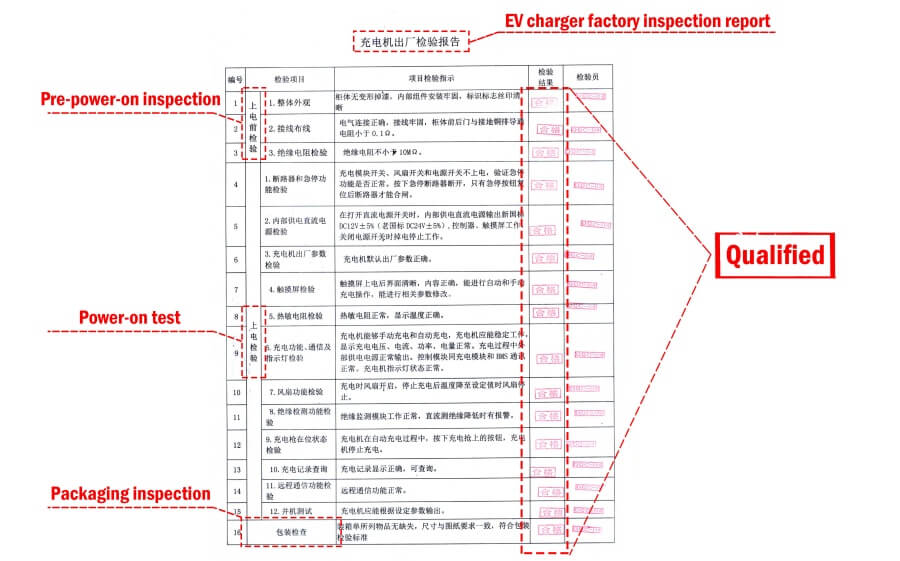

Inspeção rigorosa de pré-entrega

Atribuímos grande importância à qualidade do produto, e conduziremos até 16 inspeções novamente antes de cada entrega. Isso inclui fiação e roteamento, verificações de resistência de isolamento, verificações do disjuntor e da função de parada de emergência, verificações de CC da fonte de alimentação interna, verificações de tela sensível ao toque, verificações de termistores, verificações de função do ventilador, verificações de histórico de cobrança, verificações de função de comunicação remota, e mais.

Perguntas frequentes sobre soluções de carregamento de ônibus elétrico

Qual é a sua garantia para carregadores EV? Quanto tempo é o prazo de entrega?

Geralmente 2 anos. Se você tiver requisitos especiais, entre em contato com nosso atendimento ao cliente. O prazo de entrega é 30-45 dias úteis, depende da quantidade e do cronograma de produção.

Como são cobrados os ônibus elétricos? Que tipo de estação de carregamento um ônibus elétrico usa?

Ônibus elétricos têm bateria de grande capacidade, então eles precisam de uma estação de carregamento rápido DC para atender isso. Geralmente existem dois tipos. Uma é a estação de carregamento de ônibus elétrico de alta potência DC recomendada nesta página, e o outro é um carregador pantógrafo.

O desta página tem maior versatilidade e custo-benefício e pode carregar dois ônibus elétricos ao mesmo tempo.

O carregador do pantógrafo deve ser OEM personalizado pelo ônibus elétrico. A vantagem é o carregamento totalmente automático sem intervenção humana. A desvantagem é que é muito caro, além de não estar disponível para outros ônibus elétricos.

Quanto tempo dura um ônibus elétrico carregado?

Existem muitos fatores que afetam isso, dependendo da capacidade da bateria do seu ônibus elétrico, a potência máxima de carregamento aceita pelo BMS, a potência do ar condicionado do ônibus elétrico, e condições da estrada.

Quanto custa uma estação de carregamento de ônibus elétrico?

O custo de construção de uma estação de carregamento de ônibus elétrico varia dependendo de uma série de fatores. Isso inclui o tamanho da estação de carregamento, seleção de equipamentos, aluguel de local, transformadores, custos de construção, e subsídios governamentais. A julgar pela nossa experiência passada, deveria ser pelo menos $100,000 ou mais.