Batterie-Wärmemanagementsystem

Elektrisch betriebene Klimaanlage

Motorbetriebene Klimaanlage

Ladegeräte für Elektrofahrzeuge

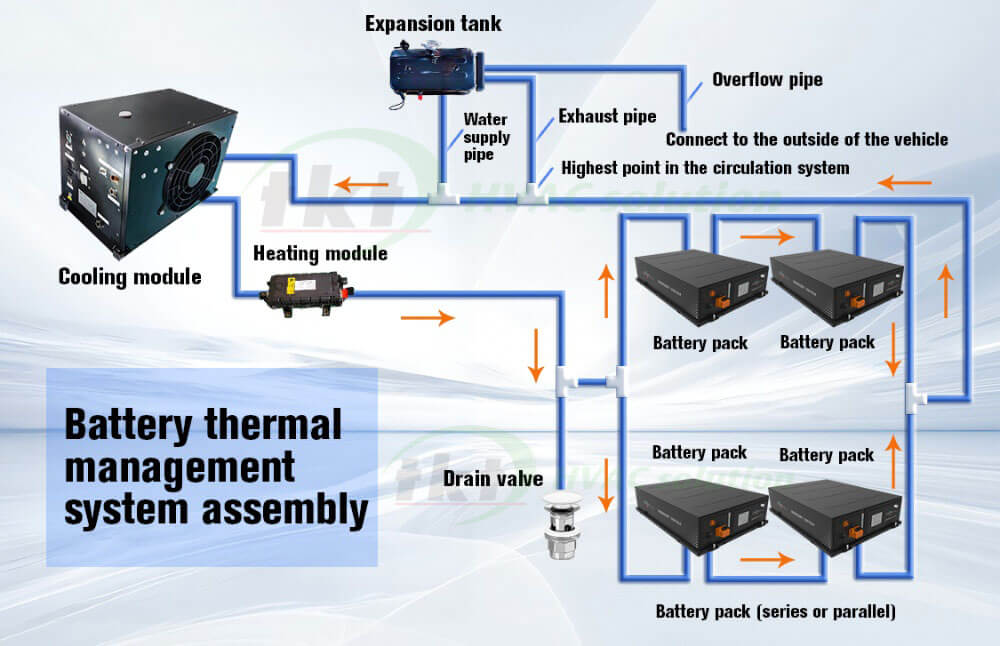

Speziell für Elektro-Lkw BTMS entwickelt, Batterieflüssigkeitskühlung.

1. Kühlkapazität: 10KW / 5KW

2. Spannungsbereich: DC 220V-750V

3. Maßgeschneidert: Heizung / OEM / Abmessungen

4. Vorteile: 0.5 ℃ präzise Temperaturregelung. Plug-and-Play. Vermögen 500 Anbieter.

Elektro-Lkw BTMS steht für Battery Thermal Management System for Electric Trucks. Es handelt sich um ein Batterietemperaturkontrollsystem, das speziell für Elektro-Lkw entwickelt wurde. Dieses System kühlt oder heizt den Akku, um sicherzustellen, dass er im optimalen Temperaturbereich arbeitet, Dadurch wird die Leistung verbessert, Sicherheit, und Lebensdauer.

Funktionsprinzip des Kühlzyklus: Eine elektronische Wasserpumpe treibt Kühlmittel durch die Kühlplatten oder Flüssigkeitskühlrohre im Batteriepaket, Absorbiert die von der Batterie erzeugte Wärme. Das Hochtemperatur-Kühlmittel wird dann zu einem Plattenwärmetauscher transportiert, where it undergoes heat exchange with the refrigerant. The cooled coolant is then recirculated back to the battery.

Purpose of the Cooling Cycle: To rapidly cool the battery during high-power charging or discharging, preventing overheating and thermal runaway.

Heating Mode Circulation Principle: The refrigeration circuit is shut off, and the PTC heater is activated to directly heat the coolant. The high-temperature coolant transfers heat to the battery pack via pipes, ensuring normal battery operation in low-temperature conditions.

Purpose of the heating mode cycle: To enhance battery chemical activity in low-temperature environments using PTC heating, preventing range degradation.

Principle of the temperature equalisation mode: Mehrere Temperatursensoren überwachen kontinuierlich die Temperatur jeder Zelle im Akkupack. Das Steuersystem passt die Kühlmitteldurchflussrate und die Kühl-/Heizleistung dynamisch an, um Temperaturunterschiede zwischen den Zellen zu reduzieren.

Zweck des Temperaturausgleichsmodus: Um Temperaturunterschiede zwischen Batteriezellen zu reduzieren, lokale Überhitzung oder Unterkühlung verhindern, und die Batterielebensdauer verlängern.

| Modell | 10CW | 5CW |

| Kühlkapazität | 10KW | 5KW |

| Standardabmessungen | 780*430*380mm | 620*350*414.5mm |

| Standardgewicht | 40kg | 30kg |

| Luftauslassrichtung | Seite | Seite |

Kontaktieren Sie uns, um das BTMS-PDF zu erhalten

Dies ist die zweite Zusammenarbeit nach unserer ersten Partnerschaft im Jahr 2018 für die Elektrobus-BTMS-Projekt. Der Schwerpunkt dieses Projekts liegt auf dem leichten Elektro-Lkw BTMS. Es spiegelt das Vertrauen wider, das TATA Motors uns entgegenbringt, ein Glücksglobal 500 Unternehmen, und dient als Anerkennung unserer gestalterischen Fähigkeiten, Produktqualität, und After-Sales-Support.

Klicken Sie hier, um weitere Bilder von Kooperationsfällen anzuzeigen

zuerst, Die Kernziele dieser beiden BTMS-Systeme sind konsistent. Beide zielen darauf ab, sicherzustellen, dass Lithium-Ionen-Batterien innerhalb ihres optimalen Temperaturbereichs arbeiten, um ein thermisches Durchgehen zu verhindern, Maximieren Sie die Batterieleistung, verlängern die Batterielebensdauer, und die Fahrzeugreichweite aufrechterhalten.

1. Kühlleistung

Batteriepakete für Elektro-Lkw sind riesig, mit Kapazitäten, die typischerweise fünf- bis zehnmal größer sind als die von Personenkraftwagen. Dies führt zu einer erheblichen Gesamtwärmeentwicklung. Zusätzlich, Schwere Lkw benötigen eine extrem hohe Momentanleistung, beispielsweise beim Beschleunigen oder Bergauffahren. daher, Elektro-Lkw-BTMS müssen außergewöhnlich gut konstruiert sein, um der extremen Hitze standzuhalten, die bei schweren Lasten entsteht, Hochgeschwindigkeitsfahren, oder Schnellladung. Die Durchflussrate des Kühlsystems, Wärmeaustauschbereich, und Kühlergröße müssen deutlich vergrößert werden.

Im Gegensatz, Elektrische Personenkraftwagen haben relativ kleinere Batteriepakete und einen geringeren Strombedarf. Typischerweise, ein einzelner Kühlkreislauf oder ein Batterie-Luftkühlsystem ist ausreichend.

2. Systemkomplexität und Kosten

Elektro-Lkw-BTMS stellen strenge Anforderungen an die Kühlkapazität. Die enormen Anforderungen an die Wärmeableitung erfordern größere Wasserpumpen, Kompressoren, Wärmetauscher, mehr Kühlmittel, und komplexere Rohrleitungen. Die Komplexität des Systemdesigns ist höher, Dies führt zu deutlich höheren Kosten im Vergleich zu Pkw.

Herkömmliche Elektrofahrzeugsysteme sind relativ einfach, was zu geringeren Kosten führt.

Zusammenfassend, Das BTMS für Elektro-Lkw ist eine speziellere Lösung zur Bewältigung extremer thermischer Belastungen mit strengen Leistungsanforderungen. Im Gegensatz, Das BTMS für Personenkraftwagen konzentriert sich auf die Bereitstellung einer Wärmemanagementleistung, die den täglichen Bedarf bei begrenzten Platz- und Kostenbeschränkungen erfüllt.

Klicken Sie hier, um zur Startseite der BTMS-Lösung zurückzukehren.

1. “Batterie -thermisches Managementsystem für Elektrofahrzeuge und Akkulaufzeit” Klicken Sie hier, um es anzuzeigen

2. “Analyse des Batteriekühlsystems für den elektrischen Bus, LKW” Klicken Sie hier, um es anzuzeigen

3. “Batterieflüssigkeitskühlsystem – wie funktioniert es??” Klicken Sie hier, um es anzuzeigen

4. “BYD K9-Projekt: EV-Batteriekühlsystem kombiniert mit Bus-Klimaanlage” Klicken Sie hier, um es anzuzeigen

5. “BTMS-Batterie: Prinzip, Design, Installation – TKT HVAC” Klicken Sie hier, um es anzuzeigen

6. “Batterie-Wärmemanagementsystem für LKW / Bus usw. – Lieferung nach oben 500 TATA” Klicken Sie hier, um es anzuzeigen

7. “Batterie-Wärmemanagementsystem für Switch-Mobilität – TKT” Klicken Sie hier, um es anzuzeigen

8. “Benutzerdefiniertes Batterie-Wärmemanagementsystem (BTMS) – TKT HVAC” Klicken Sie hier, um es anzuzeigen

9. “So entwerfen Sie den Installationsort für Bus BTMS” Klicken Sie hier, um es anzuzeigen

10. “Batteriekühlung | Batterie-Wärmemanagementsystem – TKT” Klicken Sie hier, um es anzuzeigen

Klicken Sie hier, um zur Startseite der BTMS-Lösung zurückzukehren.

Klicken Sie hier, um zu durchsuchen BTMS-Lösungen für Elektrobusse

Klicken Sie hier, um zu durchsuchen BTMS-Lösungen für Elektro-Lkw

Klicken Sie hier, um zu durchsuchen BTMS-Lösungen für elektrische Schwermaschinen

Klicken Sie hier, um zu durchsuchen BTMS-Lösungen für die Elektroschifffahrt

Klicken Sie hier, um zu durchsuchen OEM-maßgeschneiderte BTMS-Lösungen

In diesem Artikel werden einige gescheiterte Fälle verwendet, um die Risiken einer Investition in Ladestationen für Elektrofahrzeuge zu veranschaulichen. Verpassen Sie es nicht, wenn Sie interessiert sind!

Verstehen Sie das 60-kW-Ladegerät für Elektrofahrzeuge: Ihre bevorzugte Wahl für schnelle und effiziente Ladelösungen für Elektrofahrzeuge. TKT ist ein professioneller Hersteller.

Die elektrische Dreirad-Rikscha hat sich zur besten Wahl für den Kurzstreckenverkehr in Städten und ländlichen Gebieten entwickelt.