Creating an Efficient and Reliable Solution for Electric Bus Charging

TKT electric bus charging stations have been developed, designed, and manufactured since 2014. We have extensive OEM experience. Our smart, fast charging systems are designed to meet the needs of public transport fleets, including providing OEM customization. Actuellement, we are working with some of the world’s top 500 customers such as BYD and TATA motors.

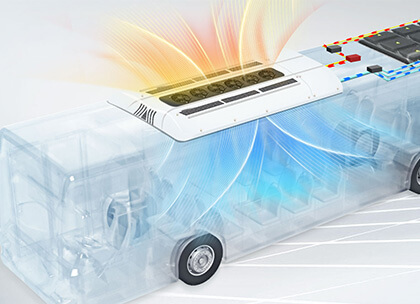

Electric buses, as a mode of public transportation, are usually required to operate around the clock. High passenger capacity, frequent starting and stopping, and energy consumption of auxiliary equipment such as air conditioners result in much higher power consumption than ordinary electric vehicles. Donc, they are usually equipped with a larger battery capacity, which reduces the number of recharging times. They are also usually equipped with faster charging speeds to ensure continuous operation.

For all these reasons, we have designed this electric bus charging solution: 120~240kW. It has two charging ports and can charge two electric buses at the same time, which can increase the utilization rate. Deuxièmement, it has a very fast charging speed, which can significantly reduce the charging dwell time of electric buses.

120-240 KW DC Station de charge rapide (Cliquez pour plus de détails)

One Hour Charging Adds About 240-480 kilomètres:

Electric buses generally consume between 56 et 60 kWh of electricity per 100 kilomètres. If a 120kW charger is used to charge an electric bus, theoretically, 120 kWh of electricity can be charged per hour. The range of the electric bus is then approximately 240 kilomètres. It should be noted that the actual charging efficiency and range may be affected by a number of factors, such as the efficiency of the charger, température ambiante, vehicle load, etc.. The above calculations are for reference only.

If a 120kw electric bus charging station charges two electric buses at the same time, the charging power of each vehicle will become 60kw.

Contact Us Get PDF

What pain points does TKT electric bus charging solve?

1. Meets the need for high-frequency replenishment/reduced charging time (Puissance de charge élevée)

1.1 Advanced power semiconductor materials: TKT chargers use advanced power semiconductor materials such as silicon carbide (SiC) to improve conversion efficiency and reduce energy loss.

1.2 Conception modulaire: 30kW/40kW high power charging module is adopted as the base. The modular design allows the charger to flexibly expand the charging power according to your needs.

2. Meet the charging needs of multi-brand buses (Forte compatibilité)

2.1 Multi-standard interface design: support CCS2, GBT, and other charging interfaces, compatible with BYD, Yutong, TATA motors and other brands of buses.

2.2 Automatic recognition of protocol adaptation: Built-in multiple communication protocol stacks automatically recognize the charging protocols of connected electric bus charging. This improves compatibility with a wide range of electric buses and ensures a safe and fast-charging experience.

2.3 More flexible than pantograph charger: not picking the model of electric buses, it is more flexible to be used as and when it comes.

3. Minimize after-sales problems (Robuste et fiable)

3.1 Multiple protection mechanisms, including overload protection, protection contre les courts-circuits, protection contre les fuites, protection contre la température, etc., ensure the safe operation of the equipment in various working conditions.

3.2 High-quality components: selected components of famous international brands to ensure product stability and durability.

3.3 Failure self-diagnostic function: real-time monitoring of the state of the equipment, automatic detection and recording of fault information, to facilitate maintenance personnel to quickly locate the problem.

4. Enhancing Operational Efficiency (Système de gestion intelligent)

4.1 Human-computer interaction interface: Equipped with high-definition touch screen, supporting multi-language switching, intuitive operation, and improving user experience.

4.2 Cloud platform management: Provide a cloud-based management platform, support remote monitoring, data analysis, diagnostic de défaut, and other functions to improve operational efficiency.

5. Soutien & Après les ventes

TKT a une équipe de services dédiée pour fournir un support en ligne pour nos systèmes matériels et logiciels. Vous n'avez pas besoin de paniquer si des problèmes surviennent.

Comme les fabricants de chargeurs de véhicules électriques d'origine, TKT fournit également une formation sur la maintenance et le dépannage appropriés. This will help extend the life of the electric bus charging station.

-

-

Soutien & Entraînement

-

-

Service client

-

-

24 Mois de garantie

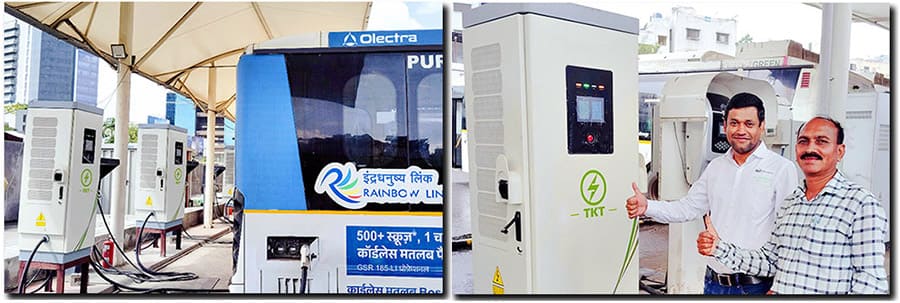

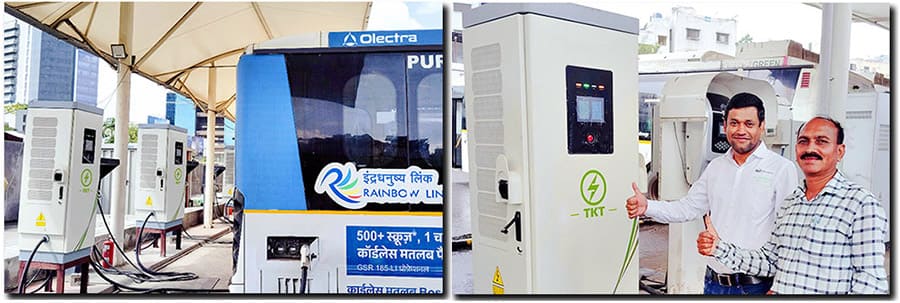

Electric Bus Charging Solution Project

Electric Bus Charging Solution Project

Le projet est notre partenariat avec BYD-Olectra, Le premier fabricant de bus électrique de l'Inde. Le nombre de chargeurs rapides pour véhicules électriques a déjà dépassé les centaines lors du premier lot.

En tant qu'ingénieur en chef électricien, M. Dinesh a mené la construction et l'entretien de l'infrastructure de charge. Il a dit, “Your electric vehicle chargers played a key role in our project. It has greatly increased the frequency of bus trips.”

About OEM/ODM

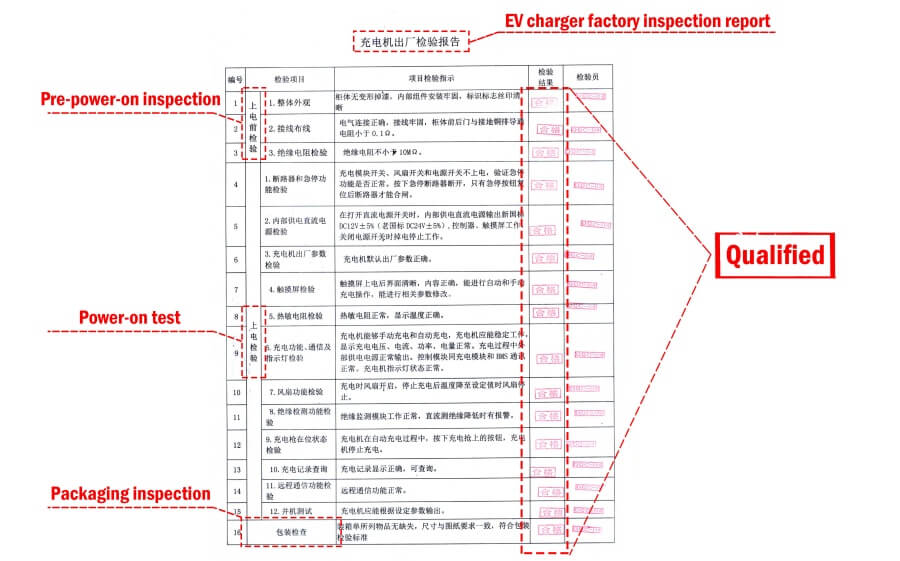

Inspection stricte avant livraison

Nous attachons une grande importance à la qualité des produits, et nous mènerons jusqu'à 16 inspections à nouveau avant chaque livraison. Ceux-ci incluent le câblage et le routage, contrôles de résistance d'isolement, vérifications du fonctionnement du disjoncteur et de l'arrêt d'urgence, Vérifications DC de l'alimentation interne, vérifications de l'écran tactile, vérifications des thermistances, contrôles du fonctionnement du ventilateur, vérifications de l'historique de charge, vérifications des fonctions de communication à distance, et plus.

Electric Bus Charging Solution FAQs

Quelle est votre garantie pour les chargeurs EV? Combien de temps est le délai de livraison?

En général 2 années. Si vous avez des exigences particulières, veuillez contacter notre service client. Le délai de livraison est 30-45 jours de travail, cela dépend de la quantité et du calendrier de production.

How are electric buses charged? What type of charging station does an electric bus use?

Electric buses have a large battery capacity, so they need a DC fast charging station to meet it. There are generally two types. One is the DC high-power electric bus charging station recommended on this page, and the other is a pantograph charger.

The one on this page has wider versatility and cost-effectiveness and can charge two electric buses at the same time.

The pantograph charger must be OEM customized by the electric bus. The advantage is fully automatic charging without human intervention. The disadvantage is that it is very expensive, as well as being unavailable for other electric buses.

How long does an electric bus go on a charge?

There are many factors affecting this, depending on your electric bus battery capacity, the maximum charging power accepted by the BMS, the power of the electric bus air-conditioner, and road conditions.

How much does an electric bus charging station cost?

The cost of constructing an electric bus charging station varies depending on a number of factors. This includes the size of the charging station, equipment selection, site rental, transformateurs, construction costs, and government subsidies. Judging from our past experience, it should be at least $100,000 or more.