Quelles sont les principales pièces de la climatisation des bus?

Le bus du climatiseur est principalement composé des composants de base suivants:

1 Compresseur de réfrigération: comprime le réfrigérant et pilote le cycle de réfrigération. C'est la partie la plus importante.

2 Condenseur et évaporateur: Le condenseur sert à dissiper la chaleur, et l'évaporateur absorbe la chaleur de la voiture pour obtenir un refroidissement.

3 Détendeur et filtre sec de stockage de liquide: régler le débit de réfrigérant et filtrer les impuretés.

3 Système de ventilateur: comprend des ventilateurs d'alimentation et de reprise d'air pour assurer la circulation de l'air.

4 Système de contrôle: contient des capteurs de température, embrayages électromagnétiques, etc., pour obtenir un contrôle automatique de la température et un réglage du mode.

Comment fonctionne la climatisation des bus?

Principe fondamental: cycle de réfrigération à compression de vapeur

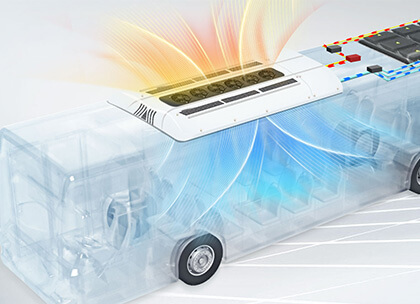

La fonction de réfrigération de la climatisation traditionnelle des bus repose principalement sur le principe de la réfrigération par compression de vapeur.. Ce principe est réalisé grâce au changement de phase du réfrigérant dans le système fermé (transition liquide-gaz) pour réaliser un transfert de chaleur. L'ensemble du processus implique les composants de base mentionnés ci-dessus: compresseur, condenseur, Soupape de détente, évaporateur. Composants auxiliaires tels que les ventilateurs, tuyauterie et commandes.

Flux de travail spécifique de la climatisation des bus

1. Compression: Le réfrigérant à l'état gazeux à basse température et basse pression est aspiré et comprimé par le compresseur, et devient un état gazeux à haute température et haute pression. Compression. Pour la climatisation traditionnelle des bus, cette source d'énergie est entraînée par le moteur du châssis à travers la courroie.

2. Condensation: Le réfrigérant gazeux à haute température et haute pression pénètre dans le condenseur situé à l'extérieur du toit du bus.. Le condenseur est équipé d'un ventilateur de condensation, qui accélère la chaleur du réfrigérant, le refroidir et le condenser dans un état liquide à haute pression.

3. Étranglement: Le réfrigérant liquide à haute pression circule à travers le détendeur, et en raison du rétrécissement soudain du pipeline, la pression chute brusquement, formant une basse température, réfrigérant liquide basse pression. Évaporation: Absorber la chaleur dans le compartiment.

4. Évaporation: Le réfrigérant liquide à basse température et basse pression pénètre dans l'évaporateur du bus. Le réfrigérant dans l'évaporateur absorbe la chaleur de l'air à l'intérieur du bus, et le réfrigérant liquide s'évapore complètement dans un liquide à basse température, état gazeux à basse pression, terminer le processus d’absorption de la chaleur.

Le réfrigérant gazeux évaporé à basse température et basse pression retourne au compresseur pour démarrer le cycle suivant..

Les climatiseurs sont-ils obligatoires dans les bus?

Il n'y a aucune exigence obligatoire pour que les bus soient équipés de climatiseurs.. Cependant, avec l’avancement de la technologie et le développement social, les exigences de confort des gens augmentent. Si une marque de bus ne peut pas offrir une expérience de conduite confortable, cela aura un impact négatif sur son image de marque.

Quand la climatisation des bus est-elle apparue pour la première fois?

D'après les informations dont nous disposons jusqu'à présent, le prototype de la technologie de climatisation des bus est né aux États-Unis en 1937, mais le bus climatisé à deux étages du Royaume-Uni en 1988 a été le premier à être mis en exploitation commerciale et à former un système complet.

Autres expressions courantes pour la climatisation des bus:

climatisation des bus porteurs, climatisation des autobus scolaires, transporteur de bus ac, climatiseur porteur pour bus, climatisation de bus trans-air, autobus climatisé, bus climatisé, bus de climatisation, bus climatisé.