Direka khas untuk peralatan berat btms, penyejukan cecair bateri.

1. Kapasiti Penyejukan: 10KW / 8KW / 5KW / 3KW

2. Julat voltan: DC 220V-750V

3. Disesuaikan: Pemanasan / OEM / Dimensi

4. Kelebihan: 0.5 ℃ Kawalan suhu yang tepat. Palam dan main. rezeki 500 pembekal.

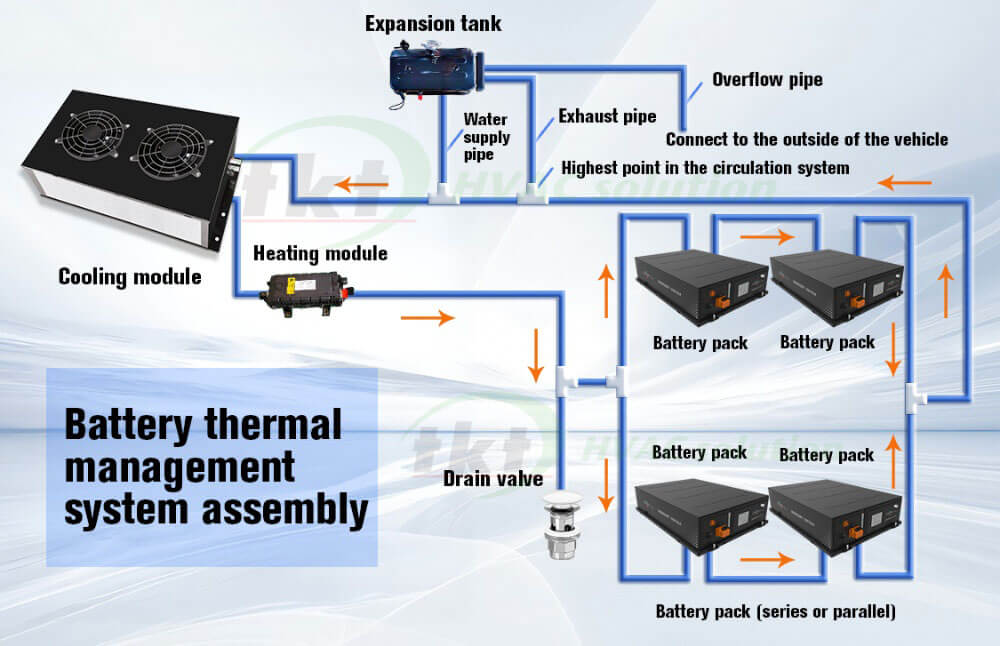

Peralatan berat biasanya merujuk kepada jentera pembinaan dan peralatan perlombongan, yang beroperasi dalam persekitaran yang keras seperti suhu tinggi, getaran tinggi, dan tahap habuk yang tinggi. Alat berat elektrik BTMS (Sistem Pengurusan Terma Bateri) ialah sistem kawalan suhu khusus yang menyejukkan dan memanaskan bateri kuasa dalam peranti ini. Bateri yang beroperasi dalam julat suhu yang sesuai boleh mencapai prestasi maksimumnya, memanjangkan jangka hayat mereka, dan mengelakkan pelarian haba dalam peralatan berat, menjadikannya lebih selamat.

Bateri dalam peralatan berat elektrik biasanya mempunyai kapasiti antara 300 kepada 600 kWh, atau pun 700 kWh. Bateri ini mengalami arus cas dan nyahcas segera yang lebih tinggi, menghasilkan lebih banyak haba dan meletakkan keperluan pelesapan haba yang lebih ketat. Oleh itu, peralatan berat BTMS memerlukan reka bentuk pelesapan haba yang teguh untuk menahan suhu yang melampau. Untuk memenuhi tuntutan ini, sistem penyejukan bateri mesti menggunakan penyejukan cecair, yang kini merupakan kaedah penyejukan bateri yang paling matang dan menjimatkan.

1. Suhu Tinggi: Suhu bateri boleh melonjak melebihi 85°C (Mis., di kawasan perlombongan padang pasir) semasa pendedahan berterusan kepada cahaya matahari atau operasi beban tinggi.

2. Getaran dan Kejutan Tinggi: Apabila beroperasi atau mengembara di kawasan yang kasar, jentera pembinaan mengalami getaran sehingga 20-50Hz, menjadikan paip penyejuk cecair tradisional terdedah kepada longgar atau kebocoran.

3. Habuk Tinggi dan Persekitaran Menghakis: Debu lombong boleh menyumbat saluran pelesapan haba dengan mudah, dan kakisan semburan garam (Mis., dalam operasi pantai) boleh menghakis komponen logam, merendahkan prestasi penebat.

4. Pengecasan dan Penyahcasan Kuasa Tinggi serta-merta: Apabila trak perlombongan elektrik memanjat cerun atau bermula di bawah beban berat, arus segera boleh mencapai ratusan ampere, menghasilkan puluhan kilowatt haba daripada bateri. Sistem penyejukan udara bateri tradisional berjuang untuk memenuhi keperluan ini.

| Model | 10CW | 8R | 5CW | 3R |

| Kapasiti Penyejukan | 10KW | 8KW | 5KW | 3KW |

| Dimensi standard | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 587*355*242mm |

| Berat standard | 40kg | 40kg | 30kg | 25kg |

| Arah saluran udara | Sisi | Atas | Sisi | Atas |

Hubungi kami untuk mendapatkan btms pdf

TKT ditubuhkan di 1998. Kami mempunyai pengalaman reka bentuk sistem pengurusan haba bateri yang luas dan keupayaan pembuatan. Dalam 2018, kami bekerjasama dengan TATA Motors, sebuah Keberuntungan 500 syarikat, untuk membangunkan BTMS tersuai. Setelah menjalani pelbagai ujian yang ketat, produk kami mendapat pengiktirafan dan pujian. Tidak lama selepas itu, kami mengadakan kerjasama kedua dengan mereka pada a BTMS untuk trak elektrik.

BTMS dan BMS untuk peralatan berat elektrik adalah dua subsistem teras sistem bateri. Mereka mencapai pengurusan bateri yang komprehensif melalui perkongsian data dan kawalan kolaboratif.

1. Perkongsian Data: BMS menghantar parameter bateri seperti SOC, SOH, dan cas dan nyahcas arus ke BTMS dalam masa nyata. BTMS melaraskan kuasa penyejukan dan pemanasan secara dinamik berdasarkan data ini.

2. Kawalan Kolaboratif: Apabila BMS mengesan penggera terlalu panas, ia serta-merta memulakan penyejukan paksa. Jika ia meramalkan suhu rendah, ia memulakan pemanasan awal. Sebaliknya, jika BTMS mengesan kegagalan sistem penyejukan, ia secara automatik mengehadkan kuasa cas dan nyahcas untuk mengelakkan bateri terlalu panas. Mereka bekerjasama untuk memastikan keselamatan peralatan dan mengelakkan fenomena dahsyat pelarian haba.

1. “Sistem pengurusan terma bateri untuk kenderaan elektrik dan hayat bateri” Klik di sini untuk melihat

2. “Analisis sistem penyejukan bateri untuk bas elektrik, Lori” Klik di sini untuk melihat

3. “Sistem Penyejukan Cecair Bateri - Bagaimana ia berfungsi?” Klik di sini untuk melihat

4. “Projek BYD K9: Sistem Penyejukan Bateri EV Digabungkan dengan A/C Bas” Klik di sini untuk melihat

5. “Bateri BTMS: Prinsip, Reka bentuk, Pemasangan - TKT HVAC” Klik di sini untuk melihat

6. “Sistem Pengurusan Terma Bateri untuk Lori / Bas dll. - dibekalkan ke bahagian atas 500 TATA” Klik di sini untuk melihat

7. “Sistem Pengurusan Thermal Bateri untuk Mobiliti Tukar - TKT” Klik di sini untuk melihat

8. “Sistem Pengurusan Terma Bateri Tersuai (BTMS) - TKT HVAC” Klik di sini untuk melihat

9. “Cara Merekabentuk Lokasi Pemasangan BTMS Bas” Klik di sini untuk melihat

10. “Penyejukan Bateri | Sistem Pengurusan Thermal Bateri - TKT” Klik di sini untuk melihat

Klik untuk melayari Penyelesaian BTMS untuk bas elektrik

Klik untuk melayari Penyelesaian BTMS untuk Lori Elektrik

Klik untuk melayari Penyelesaian BTMS untuk peralatan berat elektrik

Klik untuk melayari Penyelesaian BTMS untuk Marin Elektrik

Klik untuk melayari Penyelesaian BTMS disesuaikan OEM

Artikel ini akan menggunakan beberapa kes yang gagal untuk menggambarkan risiko pelaburan stesen pengecas EV. Jangan ketinggalan jika anda berminat!

Memahami pengecas EV 60kw: Pilihan pilihan anda untuk penyelesaian pengecasan EV yang cepat dan cekap. TKT adalah pengeluar profesional.

Rickshaw tiga roda elektrik telah menjadi pilihan terbaik untuk perjalanan jarak jauh di bandar dan kawasan luar bandar.