Electric Truck BTMS Overview

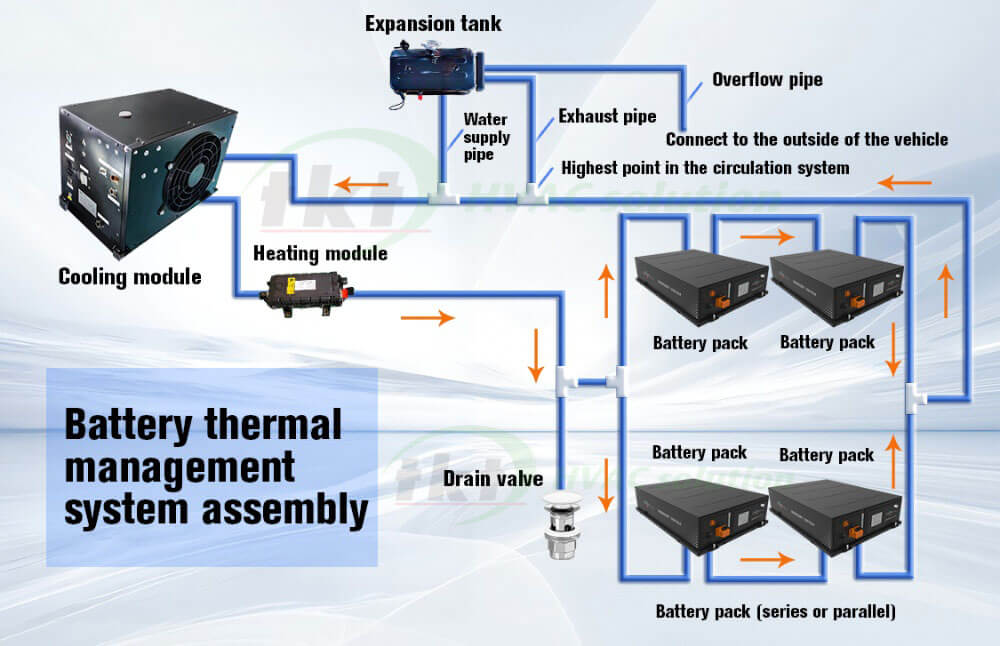

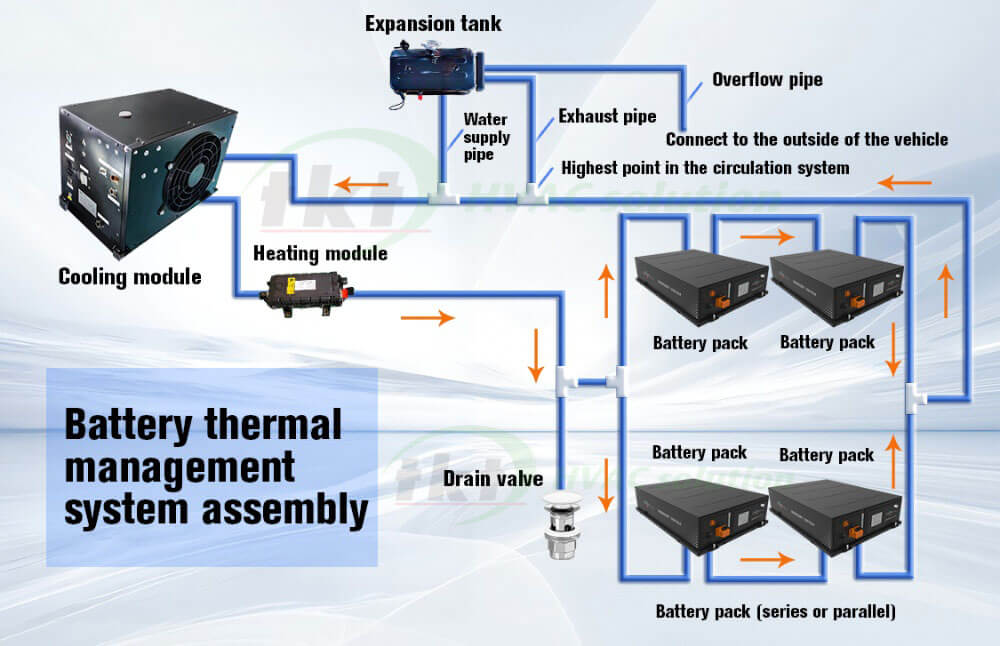

Electric truck BTMS stands for Battery Thermal Management System for electric trucks. It is a battery temperature control system designed specifically for electric trucks. This system cools or heats the battery pack to ensure it operates within the optimal temperature range, thereby improving performance, seguridad, and lifespan.

Core Functions of the Electric Truck BTMS

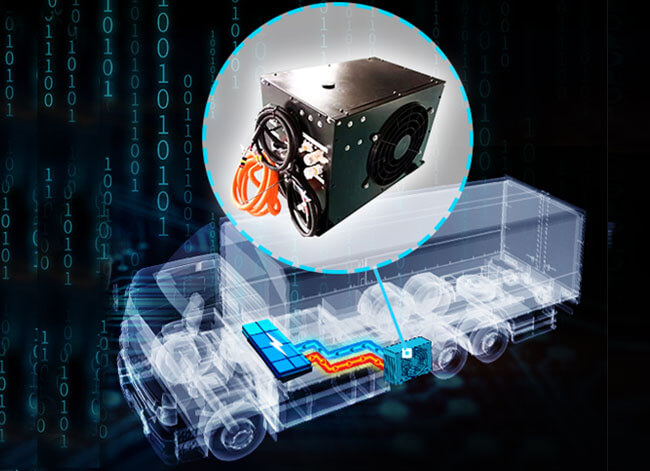

Enfriamiento

Cooling Cycle Operating Principle: An electronic water pump drives coolant through the cooling plates or liquid cooling pipes within the battery pack, absorbing heat generated by the battery. The high-temperature coolant is then transported to a plate heat exchanger, where it undergoes heat exchange with the refrigerant. The cooled coolant is then recirculated back to the battery.

Purpose of the Cooling Cycle: To rapidly cool the battery during high-power charging or discharging, preventing overheating and thermal runaway.

Calefacción

Heating Mode Circulation Principle: The refrigeration circuit is shut off, and the PTC heater is activated to directly heat the coolant. The high-temperature coolant transfers heat to the battery pack via pipes, ensuring normal battery operation in low-temperature conditions.

Purpose of the heating mode cycle: To enhance battery chemical activity in low-temperature environments using PTC heating, preventing range degradation.

Temperature Equalisation

Principle of the temperature equalisation mode: Multiple temperature sensors continuously monitor the temperature of each cell within the battery pack. The control system dynamically adjusts the coolant flow rate and cooling/heating power to reduce temperature differences between cells.

Purpose of the temperature equalisation mode: To reduce temperature differences between battery cells, prevent local overheating or overcooling, and extend battery lifespan.

Electric Truck BTMS Specification Sheet

|

Modelo |

10CW |

5CW |

|

Capacidad de enfriamiento |

10kilovatios |

5kilovatios |

|

Dimensiones estándar |

780*430*380milímetros |

620*350*414.5milímetros |

|

Peso estándar |

40kg |

30kg |

|

Dirección de salida de aire |

Lado |

Lado |

Contáctenos para obtener el BTMS PDF

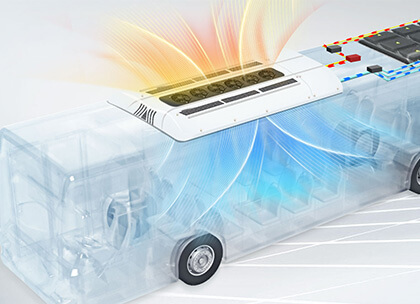

TKT Electric Truck BTMS Cooperation Projects

This marks the second collaboration following our initial partnership in 2018 for the electric bus BTMS project. This project focuses on the light-duty electric truck BTMS. It reflects the trust placed in us by TATA Motors, una fortuna global 500 compañía, and serves as recognition of our design capabilities, calidad del producto, y apoyo postventa.

-

-

Electric Truck BTMS For TATA

-

-

tata – Fortuna 500 Compañía

Haga clic para ver más imágenes de casos de cooperación