As global industries transition toward greener development, electric ships have become a key area of technological upgrading. As the power source of ships, the safety and performance of batteries directly depend on a set of key technologies: the marine BTMS (배터리 열 관리 시스템). This intelligent temperature management system, designed specifically for marine lithium-ion batteries, utilizes advanced liquid cooling technology to ensure safe operation of battery packs in complex marine environments. Its primary functions include safety monitoring, energy efficiency optimization, and life extension. It is suitable for a variety of applications, including ro-ro passenger ferries, cargo ships, fishery administration vessels, and new energy vessels.

Marine battery thermal management systems (비티엠에스) and electric bus BTMS share core functionalities: both require precise temperature control, efficient balancing, and intelligent management to ensure battery safety and performance. 하지만, the more specialized environments of marine BTMS require some differences in their technical implementation path compared to electric buses.

1. Salt spray and humid environments: Ships operate in high salt spray and high humidity environments, requiring BTMS system to possess enhanced corrosion resistance.

2. Vibration and shock: The continuous vibration and shock generated during ship operation necessitate reinforced mounting structures to ensure system stability.

| 모델 | 10CW | 8아르 자형 | 5CW | 5아르 자형 |

| 냉방 능력 | 10KW | 8KW | 5KW | 5KW |

| 표준 치수 | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 750*550*293mm |

| 표준중량 | 40kg | 40kg | 30kg | 40kg |

| 공기 배출 방향 | 옆 | 맨 위 | 옆 | 맨 위 |

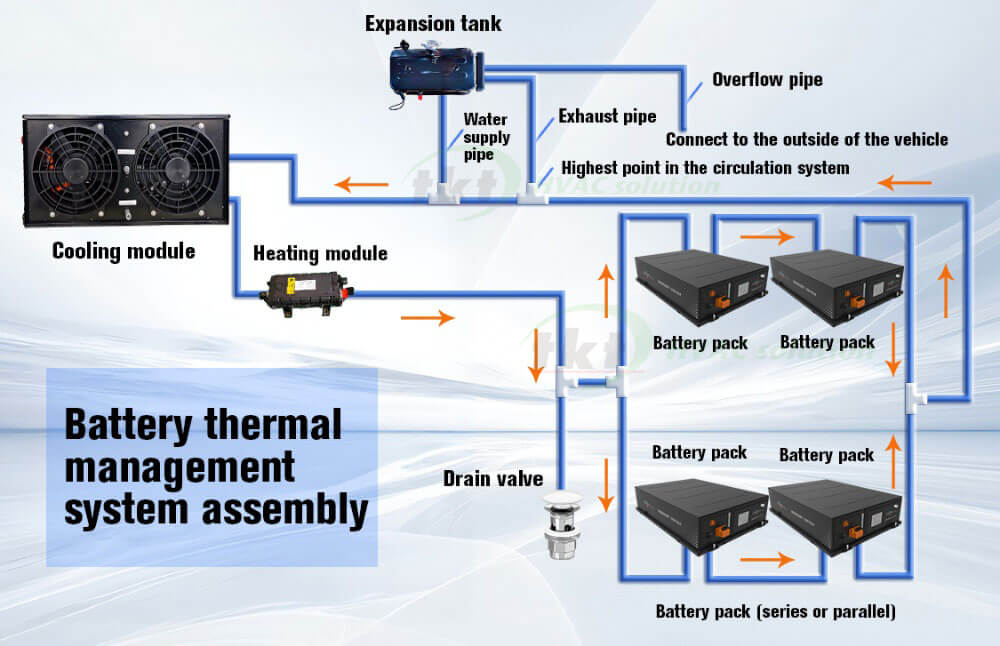

The coolant absorbs heat from the battery module, flows through a plate heat exchanger, transfers the heat to an external cooling system, and then returns to the battery module for a repeat cycle after cooling itself.

1. Liquid Cold Plate: Integrated within the battery pack, it utilizes highly thermally conductive material to maximize contact area.

2. Electronic Water Pump: Provides a stable coolant flow and serves as the power source.

3. Expansion Tank: Compensates for thermal expansion and contraction of the coolant, preventing cavitation.

1. “전기 자동차 및 배터리 수명을위한 배터리 열 관리 시스템” 보려면 여기를 클릭하세요

2. “전기 버스 용 배터리 냉각 시스템 분석, 트럭” 보려면 여기를 클릭하세요

3. “배터리 액체 냉각 시스템 - 어떻게 작동합니까??” 보려면 여기를 클릭하세요

4. “BYD K9 프로젝트: 버스 A/C와 결합된 EV 배터리 냉각 시스템” 보려면 여기를 클릭하세요

5. “BTMS 배터리: 원칙, 설계, 설치 – TKT HVAC” 보려면 여기를 클릭하세요

6. “트럭용 배터리 열 관리 시스템 / 버스 등. – 상단에 제공 500 안녕” 보려면 여기를 클릭하세요

7. “스위치 이동성을 위한 배터리 열 관리 시스템 - TKT” 보려면 여기를 클릭하세요

8. “맞춤형 배터리 열 관리 시스템 (비티엠에스) – TKT HVAC” 보려면 여기를 클릭하세요

9. “버스 설계방법 BTMS 설치위치” 보려면 여기를 클릭하세요

10. “배터리 냉각 | 배터리 열 관리 시스템 – TKT” 보려면 여기를 클릭하세요

탐색하려면 클릭하십시오 전기 버스용 BTMS 솔루션

탐색하려면 클릭하십시오 전기 트럭용 BTMS 솔루션

탐색하려면 클릭하십시오 전기중장비용 BTMS 솔루션

탐색하려면 클릭하십시오 전기 해양용 BTMS 솔루션

탐색하려면 클릭하십시오 OEM 맞춤형 BTMS 솔루션

이 기사에서는 실패한 사례를 사용하여 EV 충전소 투자의 위험을 설명합니다.. 관심있으신 분들은 놓치지 마세요!

60kW EV 충전기 이해: 빠르고 효율적인 EV 충전 솔루션을 위한 귀하의 선호 선택. TKT는 전문 제조업체입니다..