BTMS는 배터리 열 관리 시스템을 나타냅니다.. 전기버스 BTMS는 전기버스의 전원 배터리 온도를 조절하기 위해 특별히 설계된 핵심 시스템입니다.. 배터리가 안전하고 효율적인 온도 범위 내에서 작동하도록 보장하여 성능을 향상시킵니다., 수명 연장, 그리고 열폭주를 피하세요. 전기버스 BTMS는 대용량 전원 배터리를 활용한다., 상당한 열 발생. 그러므로, 현재 액체 배터리 냉각 시스템이 사용되고 있습니다..

TKT의 전기버스 BTMS는 완전 자동화되어 있습니다.. CAN 버스를 통해 차량 컨트롤러 및 배터리 관리 시스템과 통신합니다., 배터리 온도 데이터를 실시간으로 동기화하고 작동 주파수를 조정합니다..

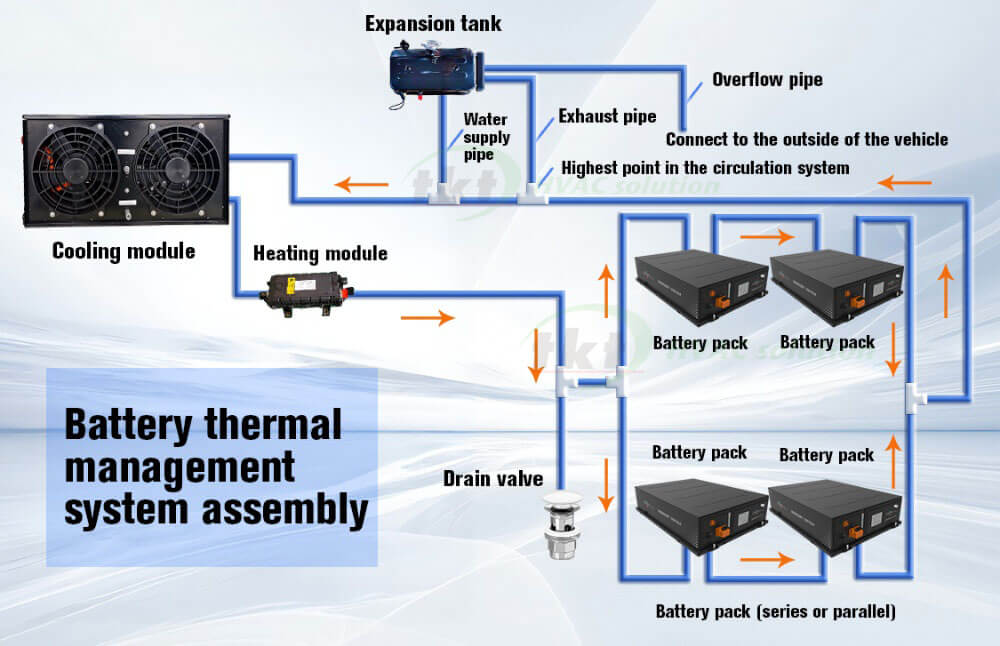

전기 버스용 BTMS 시스템에는 일반적으로 냉각 기능이 포함됩니다., 난방, 냉각, 전기 시스템.

1. 냉각 시스템은 압축기로 구성됩니다., 콘덴서, 판형 열교환기, 그리고 워터펌프. 냉각수를 순환시켜 배터리를 냉각시킵니다..

2. 가열 시스템은 PTC 온수기를 사용하여 순환액을 가열하고 배터리를 따뜻하게합니다..

3. 냉각 시스템에는 공냉식 라디에이터 탱크가 포함됩니다..

4. 전기 시스템에는 컨트롤러와 배선 장치가 포함됩니다..

| 모델 | 10CW | 8아르 자형 | 5CW | 3아르 자형 |

| 냉방 능력 | 10KW | 8KW | 5KW | 3KW |

| 표준 치수 | 780*430*380mm | 936*438*287mm | 620*350*414.5mm | 587*355*242mm |

| 표준중량 | 40kg | 40kg | 30kg | 25kg |

| 공기 배출 방향 | 옆 | 맨 위 | 옆 | 맨 위 |

이르면 2018, TATA Motors와 깊은 파트너십을 맺었습니다., 운 500 회사. 9m 전기버스 에어컨 및 전기버스 BTMS를 맞춤 개발하였습니다.. 여러 차례의 엄격한 테스트를 거친 후, 우리는 전기 버스 에어컨 및 BTMS 지정 공급업체가 되었습니다..

그후, TATA Motors는 우리와 또 다른 협업 프로젝트를 시작했습니다. 전기트럭의 BTMS 시스템. 이러한 협업은 우리의 디자인 역량을 입증하는 역할을 합니다., 제품 품질, 그리고 판매 후 지원.

장점

1. 효율적인 열 방출

액체의 열전도율이 높습니다., 충전 및 방전 시 발생하는 많은 양의 열을 빠르게 방출합니다.. 특히 고온 환경 및 대용량 전원 배터리에 적합합니다..

2. 우수한 온도 균일성

배터리 냉각판 설계로 액체와 배터리 사이에 넓은 접촉 면적 제공, 지역 핫스팟 감소. 이를 통해 배터리 간 온도차를 정밀하게 제어하고 온도차를 최소화할 수 있습니다..

단점

1. 높은 시스템 복잡성

워터 펌프와 같은 구성 요소의 통합이 필요합니다., 관, 그리고 물개, 체중 증가.

2. 높은 비용

더 많은 구성 요소가 필요합니다, 좀 더 세련된 디자인, 공랭식보다 조립이 더 복잡함.

장점:

1. 간단하고 안정적인 구조

액체 순환 시스템이 필요하지 않습니다.; 공기 흐름은 팬에 의해서만 구동됩니다.. 소형 배터리 팩 또는 보조 냉각 시나리오에 적합.

2. 저렴한 비용

생산 비용 절감 및 액체 교체 비용 없음.

단점:

1. 낮은 방열 효율.

공기 열전도율이 낮아 고온 환경에서 배터리 온도 제어가 어렵습니다. (예를 들어, 45°C 이상), 쉽게 열 폭주로 이어질 수 있습니다..

2. 온도 일관성이 좋지 않음.

부적절한 공기 덕트 설계로 인해 배터리 모듈 간에 10°C 이상의 온도 차이가 발생할 수 있습니다., 배터리 수명과 안전에 영향을 미치는.

요약하자면, 전기 버스의 고전압 전원 배터리는 상당한 에너지와 열을 발생시킵니다., 액체 배터리 냉각 시스템이 필요함. 공기 냉각 시스템은 이러한 냉각 요구 사항을 충족할 수 없습니다..

1. “전기 자동차 및 배터리 수명을위한 배터리 열 관리 시스템” 보려면 여기를 클릭하세요

2. “전기 버스 용 배터리 냉각 시스템 분석, 트럭” 보려면 여기를 클릭하세요

3. “배터리 액체 냉각 시스템 - 어떻게 작동합니까??” 보려면 여기를 클릭하세요

4. “BYD K9 프로젝트: 버스 A/C와 결합된 EV 배터리 냉각 시스템” 보려면 여기를 클릭하세요

5. “BTMS 배터리: 원칙, 설계, 설치 – TKT HVAC” 보려면 여기를 클릭하세요

6. “트럭용 배터리 열 관리 시스템 / 버스 등. – 상단에 제공 500 안녕” 보려면 여기를 클릭하세요

7. “스위치 이동성을 위한 배터리 열 관리 시스템 - TKT” 보려면 여기를 클릭하세요

8. “맞춤형 배터리 열 관리 시스템 (비티엠에스) – TKT HVAC” 보려면 여기를 클릭하세요

9. “버스 설계방법 BTMS 설치위치” 보려면 여기를 클릭하세요

10. “배터리 냉각 | 배터리 열 관리 시스템 – TKT” 보려면 여기를 클릭하세요

탐색하려면 클릭하십시오 전기 버스용 BTMS 솔루션

탐색하려면 클릭하십시오 전기 트럭용 BTMS 솔루션

탐색하려면 클릭하십시오 전기중장비용 BTMS 솔루션

탐색하려면 클릭하십시오 전기 해양용 BTMS 솔루션

탐색하려면 클릭하십시오 OEM 맞춤형 BTMS 솔루션

이 기사에서는 실패한 사례를 사용하여 EV 충전소 투자의 위험을 설명합니다.. 관심있으신 분들은 놓치지 마세요!

60kW EV 충전기 이해: 빠르고 효율적인 EV 충전 솔루션을 위한 귀하의 선호 선택. TKT는 전문 제조업체입니다..