TKT® ha terminado 25 Años de experiencia en el sistema HVAC de autobuses. Ya sea que se enfríe o se calienta, si se trata de un autobús de combustible, autobús eléctrico, bus de dos pisos, autobús del aeropuerto, autobús, u otros modelos, Como proveedor de confianza para la fortuna 500 Empresas BYD y Tata Motors, TKT puede proporcionar soluciones de alta calidad adecuadas y validadas.

Por qué elegir el sistema HVAC de bus TKT®?

TKT HVAC usa compresores de marca como Sanyo/Bock, junto con componentes centrales de alta calidad, Para garantizar una larga vida útil y un rendimiento estable.

Confiar en una R experimentada&Equipo D, El sistema de aire acondicionado de TKT Bus logra un enfriamiento rápido en áreas tropicales y ahorro de energía hasta 15%.

-

-

Comodidad maximizada

-

-

Ahorro de costos

-

-

Apoyo de expertos

-

-

Mantenimiento minimizado

Lo que obtienes

♕ Soluciones de aire acondicionador de autobús TKT®

Clientes del sistema HVAC de bus

Preguntas frecuentes del sistema HVAC HVAC

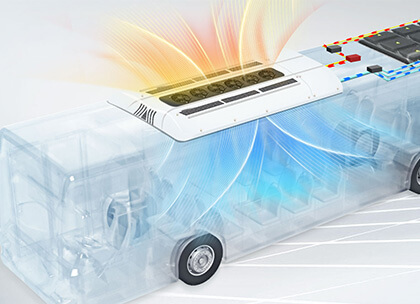

¿Qué es un sistema de bus HVAC??

El autobús HVAC (Calefacción, Ventilación y Aire Acondicionado) es un sistema de equipo integral instalado en el bus para garantizar la temperatura interna, humedad y calidad del aire. Proporciona un ambiente de conducción cómodo y saludable para los pasajeros y los conductores., y también es muy importante para conducir la seguridad. Los sistemas de aire acondicionado Coach son uno de los sistemas centrales esenciales de los autobuses modernos. Su diseño debe tener en cuenta el consumo de energía, confiabilidad y adaptabilidad a condiciones de trabajo complejas (tales como condiciones de carretera llena de baches, Comienza y se detiene frecuentes, etc.).

Funciones centrales del sistema HVAC de bus

h – Calefacción:

1. Utilización del calor de los residuos del motor (Común en la unidad de aire acondicionado del autobús de combustible)

Utilice el calor residual de alta temperatura en la circulación del refrigerante del motor. El calor se transfiere al aire dentro del autobús a través del intercambiador de calor, y luego voló en el autobús a través del conducto de aire.

2. Calentador eléctrico (Común en la unidad de aire acondicionado de autobuses eléctricos)

2.1 Calefacción de cerámica PTC: Energice directamente el elemento de calentamiento de cerámica para calentar directamente el aire que fluye. Estructura simple, respuesta rápida, Pero alto consumo de energía.

2.2 Tipo de bomba de calor: A través del principio del ciclo inverso, El calor se absorbe del ambiente exterior y el calor se intercambia al autobús. La alta eficiencia energética es la principal dirección de desarrollo del calentamiento eficiente de vehículos eléctricos. Pero es relativamente complejo y costoso.

V – Ventilación

Introducción de aire fresco, Aire rancio agotador, Mantener la circulación del aire en el autobús, y controlar la distribución del flujo de aire. Generalmente dividido en ventilación natural y ventilación forzada.

C.A. – Aire acondicionado / Enfriamiento

El principio de la unidad de aire acondicionado del bus es absorber el calor dentro del bus a través del cambio de fase del refrigerante (líquido y gaseoso) y descargarlo fuera del autobús. El proceso principal se divide en cuatro pasos principales: compresión, condensación, estrangulador, y evaporación. Después de absorber calor, El refrigerante gaseoso de baja temperatura y baja presión se absorbe nuevamente en el compresor para comenzar el siguiente ciclo.

De acuerdo con el modo de conducción del vehículo de autobús, se divide en:

1. Aire acondicionado conducido por el motor (fuel bus): El motor conduce el compresor a través de una correa, y el refrigerante absorbe el calor en el evaporador (reduce la temperatura del aire que fluye a través del evaporador), y luego libera calor a través del condensador (disipado por el motor o enfriado por el aire fuera del autobús), Completando el ciclo.

2. Aircón de autobús eléctrico (Pure Electric Bus): El compresor eléctrico está alimentado por la batería de alimentación a bordo para completar los pasos anteriores y circular y enfriar. Elimina la dependencia del motor, todavía puede correr cuando está estacionado, y tiene un ruido más bajo. Pero el sistema general es más complicado.

¿Cuáles son las categorías de los sistemas de bus HVAC??

1. Clasificación de la fuente de energía

1.1 AC para autobuses de combustible tradicionales: Confiar en la unidad del motor, estructura simple, y rápida velocidad de respuesta.

1.2 AC para autobuses eléctricos puros: Principalmente unidad eléctrica, complejo pero respetuoso con el medio ambiente.

1.3 CA de autobús de combustible de motor independiente: Configurar un motor independiente, especialmente utilizado para la unidad de aire acondicionado de autobuses de combustible, que puede resolver el problema de no poder usar el aire acondicionado al estacionamiento.

2. Clasificación por función

2.1 Tipo de enfriamiento único: Solo tiene una función de enfriamiento;

2.2 Tipo de enfriamiento y calefacción: tiene enfriamiento y calefacción al mismo tiempo;

2.3 Sistema integrado de aire acondicionado eléctrico y sistema de gestión térmica de batería (BTMS): Solo adecuado para autobuses eléctricos, un sistema integrado, puede enfriar la batería y los pasajeros de los vehículos eléctricos al mismo tiempo.

Cómo mantener y atender unidades de aire acondicionado del autobús?

Para garantizar eficientes, Operación confiable y a largo plazo del sistema HVAC del bus, Se requiere mantenimiento regular:

1. Filtro de aire: Limpiar o reemplazar regularmente.

2. Condensador/evaporador: polvo limpio, gatkins, manchas de aceite, etc., en las aletas.

3. Verifique el refrigerante: Verifique la presión y el nivel de líquido, y reponer o verificar si hay fugas si es necesario.

4. Revisar el cinturón (Solo una unidad de aire acondicionado de autobús de combustible): Verifique la tensión y el desgaste de la correa del compresor.

5. Verifique las conexiones de la tubería: Verifique las fugas, flojedad, y usar.

6. Verifique las tuberías de drenaje: Asegúrese de que el condensado se drene suavemente para evitar bacterias reproductores de agua estancada o fluir hacia el autobús.

7. Verifique las conexiones eléctricas: Asegúrese de que el arnés de cableado esté conectado de manera confiable y sin corrosión.

8. Prueba de operación del sistema: Verifique regularmente si el enfriamiento, calefacción, y las funciones de ventilación son normales y si el ruido es anormal.

¿Cuál es la política de garantía para TKT AC para autobuses??

Generalmente, Proporcionamos una garantía de 18 meses a partir de la fecha del envío. Si una parte falla debido a razones de calidad durante el período de garantía, Proporcionaremos repuestos gratis. Pero primero debe proporcionar una descripción de video y fallas para que el ingeniero pueda consultarlo cuidadosamente! Si necesita extender el período de garantía, Póngase en contacto con nosotros para una comunicación detallada.

Otras expresiones para el aire acondicionado del autobús:

unidad de aire acondicionado para autobús, autobús AC, sistema de aire acondicionado para autobús, Aire acondicionado de autobús de transporte, Aire acondicionado para buses, Sistemas de aire acondicionado de Coach, aire acondicionado para autobuses, climatización de autobús, aire acondicionado del autobús, aire acondicionado para minibus, unidad de aire acondicionado, etc..