Pengilang Pengecas Bas Elektrik China. Menyediakan penyelesaian tersuai untuk mengecas bas elektrik.

1. Caj satu jam: E-bas menambah kira-kira 240-480km

2. Kuasa pengecasan tinggi: 120KW hingga 240kW

3. Kuat dan boleh dipercayai: CE, Arai dan sijil lain

4. Sistem Pengurusan Pintar: Sesuai untuk pengurusan operasi

5. Keserasian yang tinggi: CCS2, CHAdeMO, dan GBT

TKT electric bus charging stations have been developed, designed, and manufactured since 2014. We have extensive OEM experience. Our smart, fast charging systems are designed to meet the needs of public transport fleets, including providing OEM customization. Pada masa ini, we are working with some of the world’s top 500 customers such as BYD and TATA motors.

Electric buses, as a mode of public transportation, are usually required to operate around the clock. High passenger capacity, frequent starting and stopping, and energy consumption of auxiliary equipment such as air conditioners result in much higher power consumption than ordinary electric vehicles. Oleh itu, they are usually equipped with a larger battery capacity, which reduces the number of recharging times. They are also usually equipped with faster charging speeds to ensure continuous operation.

For all these reasons, we have designed this electric bus charging solution: 120~240kW. It has two charging ports and can charge two electric buses at the same time, which can increase the utilization rate. Kedua, it has a very fast charging speed, which can significantly reduce the charging dwell time of electric buses.

120-240 stesen pengisian cepat kw dc (Click for details)

Electric buses generally consume between 56 dan 60 kWh of electricity per 100 kilometer. If a 120kW charger is used to charge an electric bus, theoretically, 120 kWh of electricity can be charged per hour. The range of the electric bus is then approximately 240 kilometer. It should be noted that the actual charging efficiency and range may be affected by a number of factors, such as the efficiency of the charger, suhu ambien, vehicle load, dan lain-lain. The above calculations are for reference only.

If a 120kw electric bus charging station charges two electric buses at the same time, the charging power of each vehicle will become 60kw.

1.1 Advanced power semiconductor materials: TKT chargers use advanced power semiconductor materials such as silicon carbide (SiC) to improve conversion efficiency and reduce energy loss.

1.2 Reka bentuk modular: 30kW/40kW high power charging module is adopted as the base. The modular design allows the charger to flexibly expand the charging power according to your needs.

2.1 Multi-standard interface design: support CCS2, GBT, and other charging interfaces, compatible with BYD, Yutong, TATA motors and other brands of buses.

2.2 Automatic recognition of protocol adaptation: Built-in multiple communication protocol stacks automatically recognize the charging protocols of connected electric bus charging. This improves compatibility with a wide range of electric buses and ensures a safe and fast-charging experience.

2.3 More flexible than pantograph charger: not picking the model of electric buses, it is more flexible to be used as and when it comes.

3.1 Multiple protection mechanisms, including overload protection, perlindungan litar pintas, perlindungan kebocoran, Perlindungan suhu yang lebih tinggi, dan lain-lain., ensure the safe operation of the equipment in various working conditions.

3.2 High-quality components: selected components of famous international brands to ensure product stability and durability.

3.3 Failure self-diagnostic function: real-time monitoring of the state of the equipment, automatic detection and recording of fault information, to facilitate maintenance personnel to quickly locate the problem.

4.1 Human-computer interaction interface: Equipped with high-definition touch screen, supporting multi-language switching, intuitive operation, and improving user experience.

4.2 Cloud platform management: Provide a cloud-based management platform, support remote monitoring, data analysis, Diagnosis kesalahan, and other functions to improve operational efficiency.

TKT mempunyai pasukan perkhidmatan khusus untuk memberikan sokongan dalam talian untuk sistem perkakasan dan perisian kami. Anda tidak perlu panik jika ada masalah yang timbul.

Sebagai pengeluar pengecas kenderaan elektrik asal, TKT juga menyediakan latihan mengenai penyelenggaraan dan penyelesaian masalah yang betul. This will help extend the life of the electric bus charging station.

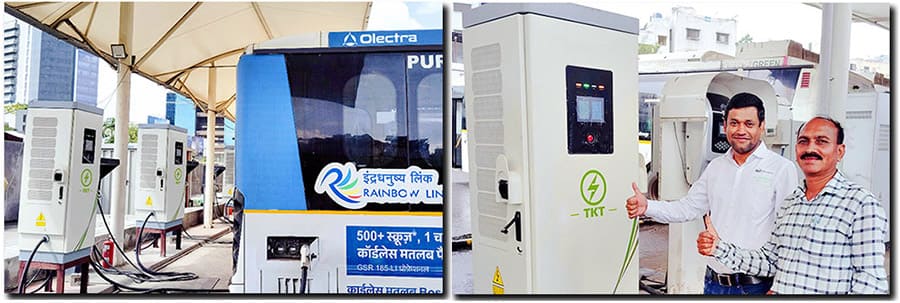

Electric Bus Charging Solution Project

Electric Bus Charging Solution ProjectProjek ini adalah perkongsian kami dengan BYD-Olectra, Pengeluar bas elektrik terkemuka India. Bilangan pengecas kenderaan elektrik cepat telah melebihi beratus -ratus dalam kumpulan pertama.

Sebagai Ketua Jurutera Elektrik, MR. Dinesh mengetuai pembinaan dan penyelenggaraan infrastruktur pengecasan. Katanya, “Your electric vehicle chargers played a key role in our project. It has greatly increased the frequency of bus trips.”

Kami mementingkan kualiti produk, dan kami akan menjalankan sehingga 16 pemeriksaan sekali lagi sebelum setiap penghantaran. Ini termasuk pendawaian dan penghalaan, pemeriksaan rintangan penebat, pemutus litar dan pemeriksaan fungsi berhenti kecemasan, pemeriksaan DC bekalan kuasa dalaman, pemeriksaan skrin sentuh, pemeriksaan termistor, pemeriksaan fungsi kipas, mengecas semakan sejarah, pemeriksaan fungsi komunikasi jauh, dan banyak lagi.

Secara amnya 2 tahun. Jika anda mempunyai keperluan khas sila hubungi perkhidmatan pelanggan kami. Masa utama ialah 30-45 hari bekerja, ia bergantung kepada kuantiti dan jadual pengeluaran.

Electric buses have a large battery capacity, so they need a DC fast charging station to meet it. There are generally two types. One is the DC high-power electric bus charging station recommended on this page, and the other is a pantograph charger.

The one on this page has wider versatility and cost-effectiveness and can charge two electric buses at the same time.

The pantograph charger must be OEM customized by the electric bus. The advantage is fully automatic charging without human intervention. The disadvantage is that it is very expensive, as well as being unavailable for other electric buses.

There are many factors affecting this, depending on your electric bus battery capacity, the maximum charging power accepted by the BMS, the power of the electric bus air-conditioner, and road conditions.

The cost of constructing an electric bus charging station varies depending on a number of factors. This includes the size of the charging station, equipment selection, site rental, transformer, construction costs, and government subsidies. Judging from our past experience, it should be at least $100,000 or more.

1. 7Butiran pengecas KW EV dan kerjasama utama dengan BYD Ketahui lebih lanjut.

2. Keselamatan Pengecas EV: Garis hidup era tenaga baru Ketahui lebih lanjut.

3. China EV Charger - Teknologi Memacu Daya Saing Ketahui lebih lanjut.

4. Voltan pengecasan EV DC: Apa yang anda mesti tahu Ketahui lebih lanjut.

5. Berapakah kos stesen pengisian EV komersial? Ketahui lebih lanjut.

6. Peluang Baharu untuk Pengecas EV Komersial Ketahui lebih lanjut.

electric bus charging infrastructure, stesen pengecas bas elektrik, electric bus charging systems, mengecas bas elektrik, electric bus charging station cost

Artikel ini akan menggunakan beberapa kes yang gagal untuk menggambarkan risiko pelaburan stesen pengecas EV. Jangan ketinggalan jika anda berminat!

Memahami pengecas EV 60kw: Pilihan pilihan anda untuk penyelesaian pengecasan EV yang cepat dan cekap. TKT adalah pengeluar profesional.

Rickshaw tiga roda elektrik telah menjadi pilihan terbaik untuk perjalanan jarak jauh di bandar dan kawasan luar bandar.