Creating an Efficient and Reliable Solution for Electric Bus Charging

TKT electric bus charging stations have been developed, designed, and manufactured since 2014. We have extensive OEM experience. Our smart, fast charging systems are designed to meet the needs of public transport fleets, including providing OEM customization. Attualmente, we are working with some of the world’s top 500 customers such as BYD and TATA motors.

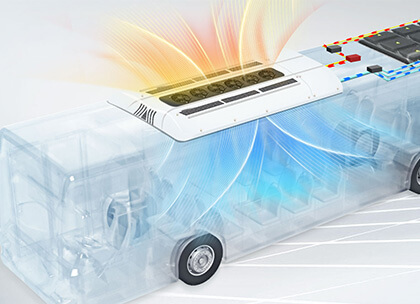

Electric buses, as a mode of public transportation, are usually required to operate around the clock. High passenger capacity, frequent starting and stopping, and energy consumption of auxiliary equipment such as air conditioners result in much higher power consumption than ordinary electric vehicles. Perciò, they are usually equipped with a larger battery capacity, which reduces the number of recharging times. They are also usually equipped with faster charging speeds to ensure continuous operation.

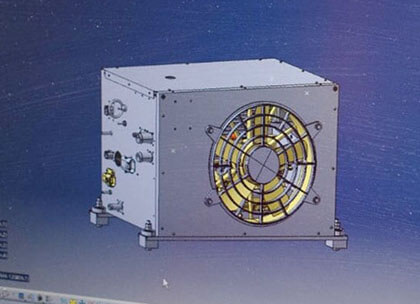

For all these reasons, we have designed this electric bus charging solution: 120~240kW. It has two charging ports and can charge two electric buses at the same time, which can increase the utilization rate. In secondo luogo, it has a very fast charging speed, which can significantly reduce the charging dwell time of electric buses.

120-240 Stazione di ricarica rapida CC da kW (Click for details)

One Hour Charging Adds About 240-480 km:

Electric buses generally consume between 56 E 60 kWh di elettricità al 100 chilometri. If a 120kW charger is used to charge an electric bus, theoretically, 120 kWh of electricity can be charged per hour. The range of the electric bus is then approximately 240 chilometri. It should be noted that the actual charging efficiency and range may be affected by a number of factors, such as the efficiency of the charger, temperatura ambiente, vehicle load, eccetera. The above calculations are for reference only.

If a 120kw electric bus charging station charges two electric buses at the same time, the charging power of each vehicle will become 60kw.

Contact Us Get PDF

What pain points does TKT electric bus charging solve?

1. Meets the need for high-frequency replenishment/reduced charging time (Potenza di ricarica elevata)

1.1 Advanced power semiconductor materials: TKT chargers use advanced power semiconductor materials such as silicon carbide (SiC) to improve conversion efficiency and reduce energy loss.

1.2 Design modulare: 30kW/40kW high power charging module is adopted as the base. The modular design allows the charger to flexibly expand the charging power according to your needs.

2. Meet the charging needs of multi-brand buses (Alta compatibilità)

2.1 Multi-standard interface design: support CCS2, GBT, and other charging interfaces, compatible with BYD, Yutong, TATA motors and other brands of buses.

2.2 Automatic recognition of protocol adaptation: Built-in multiple communication protocol stacks automatically recognize the charging protocols of connected electric bus charging. This improves compatibility with a wide range of electric buses and ensures a safe and fast-charging experience.

2.3 More flexible than pantograph charger: not picking the model of electric buses, it is more flexible to be used as and when it comes.

3. Minimize after-sales problems (Robusto e affidabile)

3.1 Multiple protection mechanisms, including overload protection, protezione da cortocircuito, protezione dalle perdite, Protezione eccessiva di temperatura, eccetera., ensure the safe operation of the equipment in various working conditions.

3.2 High-quality components: selected components of famous international brands to ensure product stability and durability.

3.3 Failure self-diagnostic function: real-time monitoring of the state of the equipment, automatic detection and recording of fault information, to facilitate maintenance personnel to quickly locate the problem.

4. Enhancing Operational Efficiency (Sistema di gestione intelligente)

4.1 Human-computer interaction interface: Equipped with high-definition touch screen, supporting multi-language switching, intuitive operation, and improving user experience.

4.2 Cloud platform management: Provide a cloud-based management platform, support remote monitoring, data analysis, diagnosi di guasto, and other functions to improve operational efficiency.

5. Supporto & Dopo le vendite

TKT ha un team di servizio dedicato per fornire supporto online per i nostri sistemi hardware e software. Non è necessario farsi prendere dal panico se sorgono problemi.

Come produttori di caricabatterie originali per veicoli elettrici, TKT fornisce anche una formazione sulla manutenzione adeguata e sulla risoluzione dei problemi. This will help extend the life of the electric bus charging station.

-

-

Supporto & Formazione

-

-

Servizi clienti

-

-

24 Mesi di garanzia

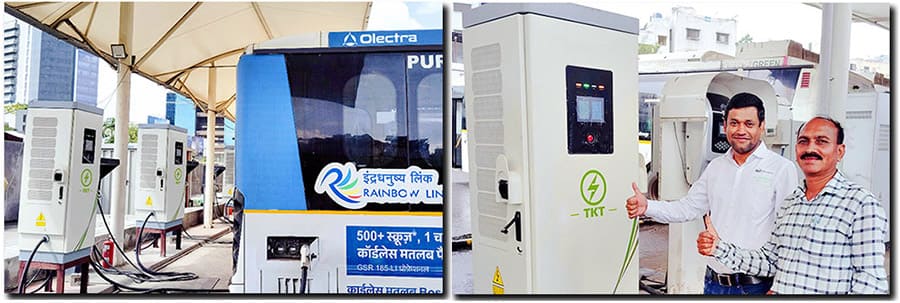

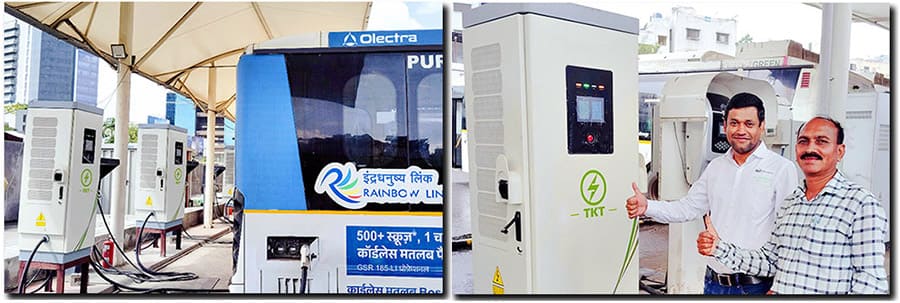

Electric Bus Charging Solution Project

Electric Bus Charging Solution Project

Il progetto è la nostra partnership con BYD-Olectra, Il principale produttore di autobus elettrici dell'India. Il numero di caricabatterie per veicoli elettrici veloci ha già superato centinaia nel primo lotto.

Come ingegnere elettrico capo, Sig. Dinesh ha guidato la costruzione e la manutenzione dell'infrastruttura di ricarica. Ha detto, “Your electric vehicle chargers played a key role in our project. It has greatly increased the frequency of bus trips.”

About OEM/ODM

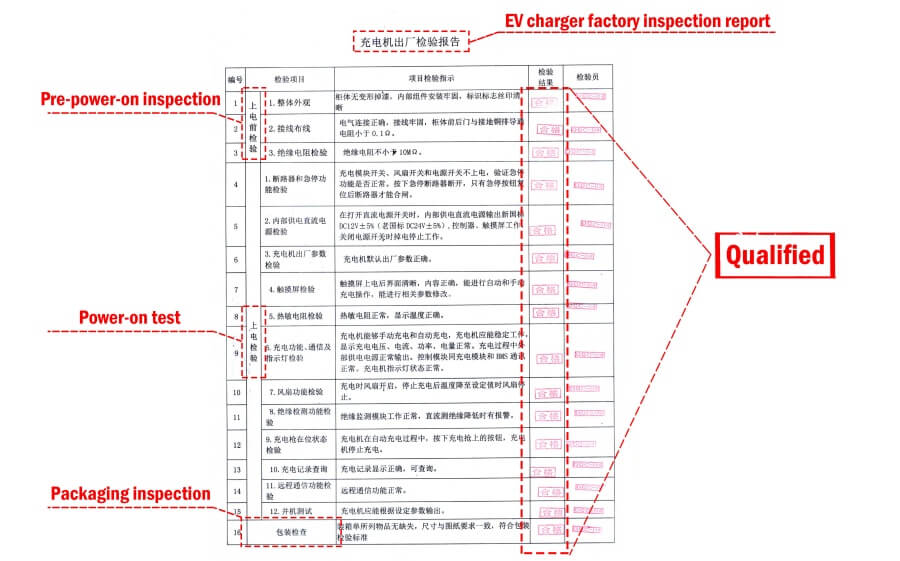

Ispezione rigorosa prima della consegna

Attribuiamo grande importanza alla qualità del prodotto, e condurremo fino a 16 ripetere le ispezioni prima di ogni consegna. Questi includono il cablaggio e il routing, verifiche della resistenza di isolamento, controlli dell'interruttore automatico e della funzione di arresto di emergenza, controlli DC dell'alimentatore interno, controlli del touch screen, controlli del termistore, controlli del funzionamento del ventilatore, controlli della cronologia di ricarica, verifiche della funzionalità di comunicazione remota, e altro ancora.

Electric Bus Charging Solution FAQs

Qual è la vostra garanzia per i caricabatterie per veicoli elettrici? Quanto è lungo il tempo di consegna??

Generalmente 2 anni. Se hai esigenze particolari contatta il nostro servizio clienti. Il tempo di consegna è 30-45 giorni lavorativi, dipende dalla quantità e dal programma di produzione.

How are electric buses charged? What type of charging station does an electric bus use?

Electric buses have a large battery capacity, so they need a DC fast charging station to meet it. There are generally two types. One is the DC high-power electric bus charging station recommended on this page, and the other is a pantograph charger.

The one on this page has wider versatility and cost-effectiveness and can charge two electric buses at the same time.

The pantograph charger must be OEM customized by the electric bus. The advantage is fully automatic charging without human intervention. The disadvantage is that it is very expensive, as well as being unavailable for other electric buses.

How long does an electric bus go on a charge?

There are many factors affecting this, depending on your electric bus battery capacity, the maximum charging power accepted by the BMS, the power of the electric bus air-conditioner, and road conditions.

How much does an electric bus charging station cost?

The cost of constructing an electric bus charging station varies depending on a number of factors. This includes the size of the charging station, equipment selection, site rental, trasformatori, construction costs, and government subsidies. Judging from our past experience, it should be at least $100,000 or more.