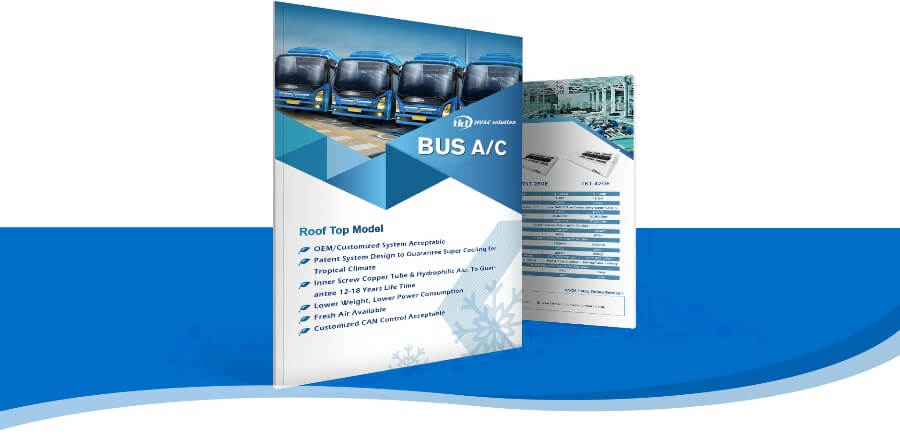

Quali sono i principali componenti dell'aria condizionata per autobus?

Il bus del condizionatore d'aria è composto principalmente dai seguenti componenti principali:

1 Compressore di refrigerazione: comprime il refrigerante e avvia il ciclo di refrigerazione. Questa è la parte più importante.

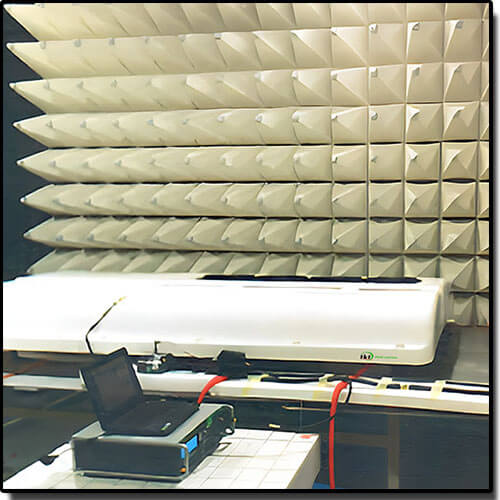

2 Condensatore ed Evaporatore: Il condensatore viene utilizzato per dissipare il calore, e l'evaporatore assorbe il calore dell'auto per ottenere il raffreddamento.

3 Valvola di espansione e filtro a secco per lo stoccaggio del liquido: regolare il flusso del refrigerante e filtrare le impurità.

3 Sistema di ventilazione: include ventilatori di mandata e ripresa per garantire la circolazione dell'aria.

4 Sistema di controllo: contiene sensori di temperatura, frizioni elettromagnetiche, eccetera., per ottenere il controllo automatico della temperatura e la regolazione della modalità.

Come funziona l'aria condizionata negli autobus??

Principio fondamentale: Ciclo frigorifero a compressione di vapore

La funzione di refrigerazione del tradizionale climatizzatore per autobus si basa principalmente sul principio della refrigerazione a compressione di vapore. Questo principio si ottiene attraverso il cambiamento di fase del refrigerante nel sistema chiuso (transizione liquido-gas) per ottenere il trasferimento di calore. L'intero processo coinvolge i componenti principali sopra menzionati: compressore, condensatore, valvola di espansione, evaporatore. Componenti ausiliari come ventilatori, tubazioni e controlli.

Flusso di lavoro specifico della climatizzazione degli autobus

1. Compressione: Il refrigerante allo stato gassoso a bassa temperatura e bassa pressione viene aspirato e compresso dal compressore, e diventa lo stato gassoso ad alta temperatura e alta pressione. Compressione. Per la climatizzazione tradizionale degli autobus, questa fonte di energia è azionata dal motore del telaio attraverso la cinghia.

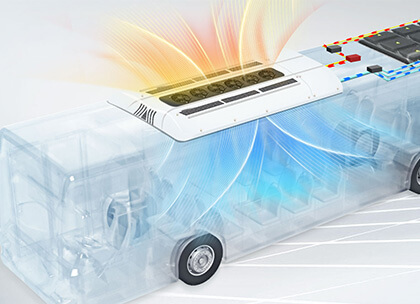

2. Condensazione: Il refrigerante gassoso ad alta temperatura e alta pressione entra nel condensatore all'esterno del tetto dell'autobus. Il condensatore è dotato di un ventilatore di condensazione, che accelera il calore lontano dal refrigerante, raffreddandolo e condensandolo in uno stato liquido ad alta pressione.

3. Limitazione: Il refrigerante liquido ad alta pressione scorre attraverso la valvola di espansione, e a causa dell'improvviso restringimento del gasdotto, la pressione scende bruscamente, formando una bassa temperatura, refrigerante liquido a bassa pressione. Evaporazione: Assorbire il calore nel vano.

4. Evaporazione: Il refrigerante liquido a bassa temperatura e bassa pressione entra nell'evaporatore del bus. Il refrigerante nell'evaporatore assorbe il calore dell'aria all'interno dell'autobus, e il refrigerante liquido evapora completamente a bassa temperatura, stato gassoso a bassa pressione, completare il processo di assorbimento del calore.

Il refrigerante gassoso evaporato a bassa temperatura e bassa pressione ritorna al compressore per avviare il ciclo successivo.

I condizionatori sugli autobus sono obbligatori??

Non esiste un obbligo obbligatorio per gli autobus di essere dotati di condizionatori. Tuttavia, con il progresso della tecnologia e dello sviluppo sociale, le esigenze di comfort delle persone sono in aumento. Se una marca di autobus non può fornire un'esperienza di guida confortevole, avrà un impatto negativo sull'immagine del marchio.

Quando è apparsa per la prima volta l'aria condizionata sugli autobus??

Secondo le informazioni che conosciamo finora, il prototipo della tecnologia di climatizzazione degli autobus è nato negli Stati Uniti nel 1937, ma l'autobus a due piani con aria condizionata nel Regno Unito 1988 è stato il primo ad essere messo in esercizio commerciale e a formare un sistema completo.

Altre espressioni comuni per l'aria condizionata degli autobus:

aria condizionata per autobus di trasporto, aria condizionata di scuolabus, autobus portante ac, condizionatore d'aria per autobus, aria condizionata per autobus trans air, autobus con aria condizionata, Autobus con aria condizionata, Autobus di aria condizionata, autobus climatizzato.